444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2150

Market Overview

India is a prominent player in the global manufacturing market and has witnessed significant growth over the years. The manufacturing sector in India contributes to the country’s economic development, employment generation, and technological advancement. With a diverse range of industries, including automotive, textiles, pharmaceuticals, electronics, and machinery, the Indian manufacturing market offers immense potential for both domestic and international investors.

Meaning

The India manufacturing market refers to the production and assembly of goods within the country. It involves various stages, including raw material sourcing, production, quality control, packaging, and distribution. The manufacturing sector plays a crucial role in driving economic growth, attracting foreign investment, and creating employment opportunities for a large number of people.

Executive Summary

The Indian manufacturing market has experienced substantial growth in recent years, driven by factors such as a large consumer base, government initiatives, technological advancements, and favorable investment policies. However, it also faces challenges such as infrastructure limitations, skill gaps, and regulatory complexities. Despite these challenges, the sector presents significant opportunities for industry participants and stakeholders.

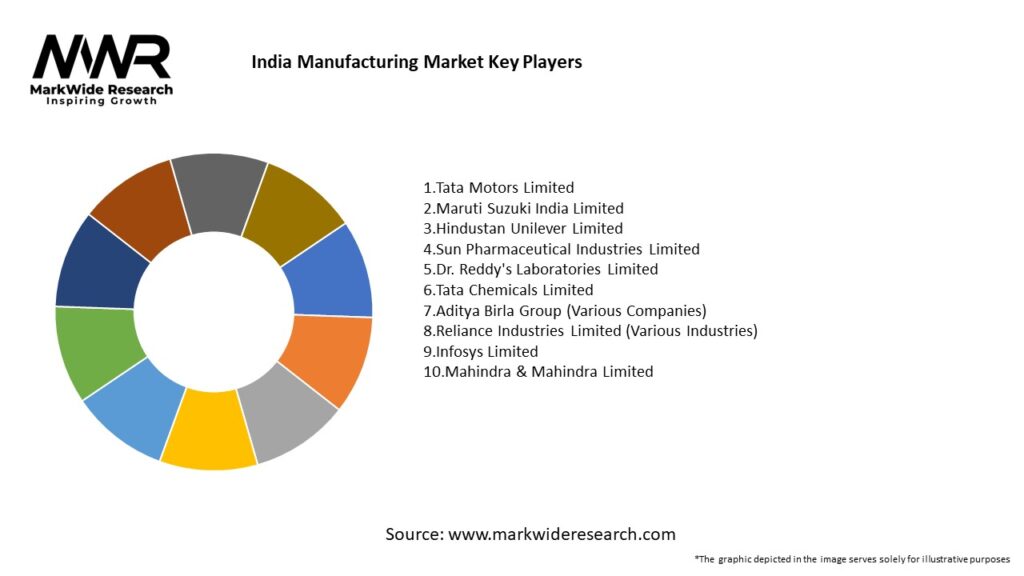

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The India manufacturing market operates in a dynamic environment influenced by various factors. Changing consumer preferences, technological advancements, government policies, global trade dynamics, and economic conditions shape the market dynamics. Manufacturers need to adapt to these dynamics and embrace innovation to stay competitive and seize growth opportunities.

Regional Analysis

The Indian manufacturing market exhibits regional variations in terms of industrial development, infrastructure, and market potential. Key manufacturing hubs in India include Maharashtra, Gujarat, Tamil Nadu, Karnataka, and Uttar Pradesh. These regions have favorable industrial ecosystems, skilled labor pools, and robust infrastructure, making them attractive destinations for manufacturing investments.

Competitive Landscape

Leading Companies in the India Manufacturing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

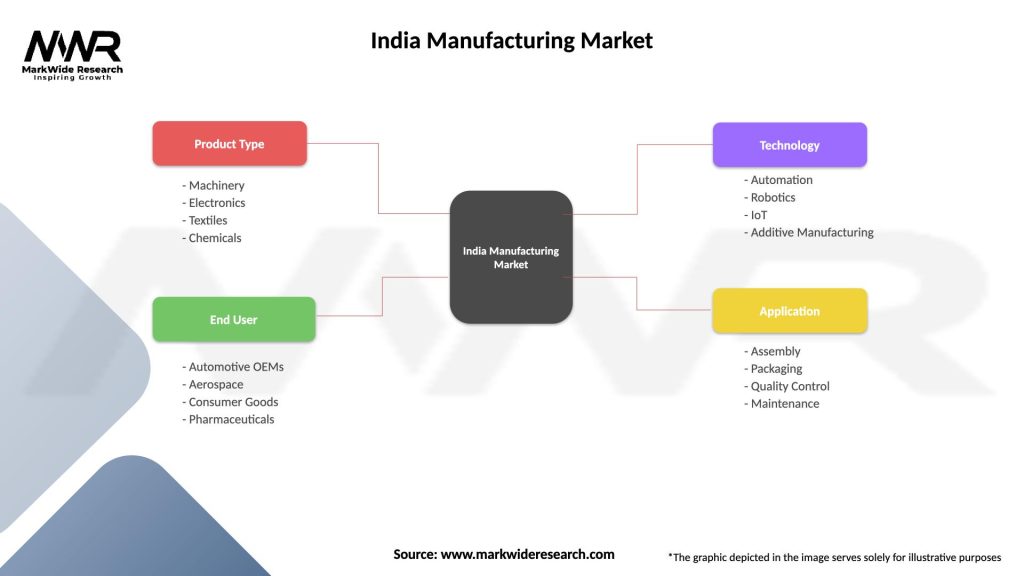

Segmentation

The Indian manufacturing market can be segmented based on various factors, including industry verticals, product types, and production processes. Some key segments include automotive manufacturing, pharmaceutical manufacturing, textile manufacturing, electronic manufacturing, and machinery manufacturing. Each segment has its unique characteristics, challenges, and growth potential.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the Indian manufacturing market. The nationwide lockdowns and disruptions in global supply chains affected production, distribution, and demand. However, the crisis also presented opportunities for certain sectors such as pharmaceuticals, medical devices, and personal protective equipment (PPE) manufacturing. The pandemic accelerated digital transformation and highlighted the need for agile and resilient manufacturing practices.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the Indian manufacturing market looks promising, driven by favorable factors such as a growing domestic market, government initiatives, technological advancements, and global demand. The sector is expected to witness increased investments, innovation, and exports. However, addressing infrastructure limitations, skill gaps, and regulatory complexities will be essential for sustainable growth and competitiveness.

Conclusion

The Indian manufacturing market presents significant opportunities for industry participants and stakeholders. With a large domestic market, government support, technological advancements, and a skilled labor force, India is well-positioned to attract investments and foster manufacturing growth. However, challenges such as infrastructure limitations, skill shortages, and regulatory complexities need to be addressed. Embracing digital transformation, sustainable practices, and fostering collaborations will be crucial for manufacturers to thrive in the dynamic and competitive Indian manufacturing market.

What is India Manufacturing?

India Manufacturing refers to the process of producing goods and products in various sectors such as textiles, automotive, electronics, and machinery within India. It encompasses a wide range of activities from raw material processing to assembly and distribution.

What are the key players in the India Manufacturing Market?

Key players in the India Manufacturing Market include Tata Group, Mahindra & Mahindra, Larsen & Toubro, and Bharat Forge, among others. These companies are involved in diverse sectors such as automotive, heavy machinery, and consumer goods.

What are the growth factors driving the India Manufacturing Market?

The India Manufacturing Market is driven by factors such as government initiatives like ‘Make in India’, increasing foreign direct investment, and a growing domestic consumer base. Additionally, advancements in technology and infrastructure development play a significant role.

What challenges does the India Manufacturing Market face?

The India Manufacturing Market faces challenges such as regulatory hurdles, inadequate infrastructure, and a skilled labor shortage. These issues can hinder production efficiency and competitiveness in the global market.

What opportunities exist in the India Manufacturing Market?

Opportunities in the India Manufacturing Market include the potential for automation and digital transformation, growth in the electric vehicle sector, and increased demand for sustainable manufacturing practices. These trends can lead to innovation and expansion in various industries.

What trends are shaping the India Manufacturing Market?

Trends shaping the India Manufacturing Market include the adoption of Industry Four Point Zero technologies, a focus on sustainability, and the rise of smart manufacturing. These trends are influencing production processes and supply chain management.

India Manufacturing Market

| Segmentation Details | Description |

|---|---|

| Product Type | Machinery, Electronics, Textiles, Chemicals |

| End User | Automotive OEMs, Aerospace, Consumer Goods, Pharmaceuticals |

| Technology | Automation, Robotics, IoT, Additive Manufacturing |

| Application | Assembly, Packaging, Quality Control, Maintenance |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the India Manufacturing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at