444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview: The India Connected Mining Market plays a pivotal role in transforming the mining industry by integrating advanced technologies. This market focuses on optimizing operations through connectivity, automation, and data-driven decision-making. With the adoption of IoT, AI, and other innovations, connected mining in India enhances efficiency, safety, and sustainability in the extraction of mineral resources.

Meaning: Connected mining in India refers to the utilization of digital technologies to interconnect various aspects of mining operations. This involves integrating sensors, automation systems, and data analytics to create a cohesive and intelligent mining ecosystem. This approach aims to streamline processes, enhance safety, and improve resource utilization in the mining sector.

Executive Summary: The India Connected Mining Market is witnessing a transformative phase, driven by technological advancements. The integration of smart solutions is revolutionizing traditional mining practices, bringing forth opportunities for increased productivity and reduced operational risks. Industry stakeholders must comprehend the nuances of this evolving landscape to harness its full potential.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics: The India Connected Mining Market operates in a dynamic landscape shaped by technological advancements, regulatory changes, and industry trends. Adapting to these dynamics is crucial for stakeholders to capitalize on opportunities and navigate challenges in this evolving market.

Regional Analysis: The regional dynamics of the India Connected Mining Market vary based on mineral-rich regions, government policies, and infrastructure development. Understanding the unique characteristics of different regions within India provides insights into the diverse applications and challenges of connected mining.

Competitive Landscape:

Leading Companies for India Connected Mining Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

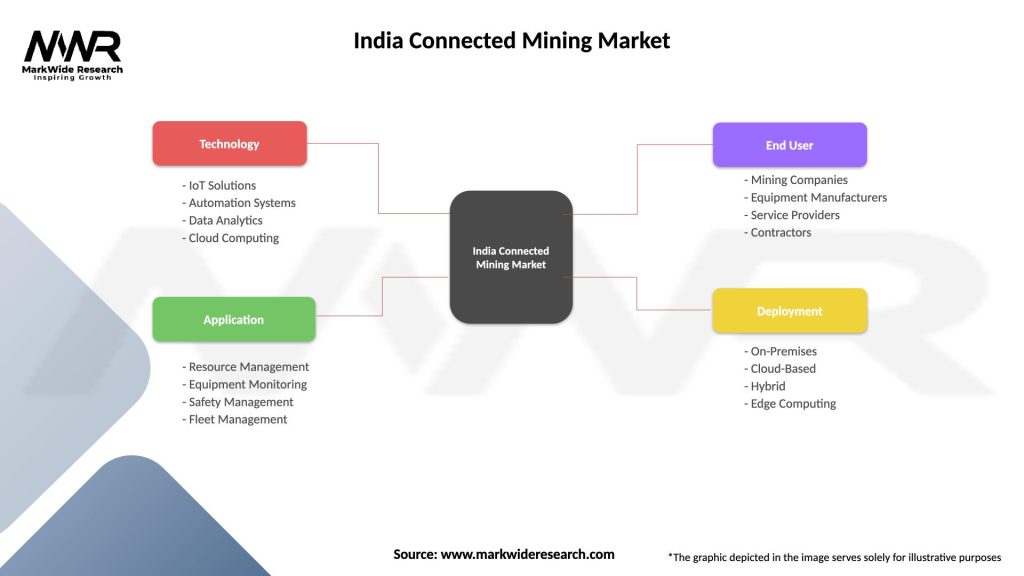

Segmentation:

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact:

Key Industry Developments:

Analyst Suggestions:

Future Outlook: The future of the India Connected Mining Market looks promising, with continued technological advancements, government support, and a growing awareness of the benefits of connected mining. As the industry navigates challenges and embraces innovation, the focus on sustainable practices and global competitiveness will shape its trajectory.

Conclusion: In conclusion, the India Connected Mining Market stands at the forefront of a technological revolution that promises to reshape the mining industry. The integration of connected technologies not only enhances operational efficiency and safety but also positions Indian mining on the global stage. With strategic investments, collaborations, and a commitment to sustainability, the industry can forge a path towards a connected and resilient future.

What is Connected Mining?

Connected Mining refers to the integration of advanced technologies such as IoT, AI, and data analytics in the mining sector to enhance operational efficiency, safety, and productivity. This approach allows for real-time monitoring and management of mining operations.

What are the key players in the India Connected Mining Market?

Key players in the India Connected Mining Market include companies like Tata Steel, Hindustan Zinc, and Sandvik, which are leveraging technology to improve mining processes and sustainability, among others.

What are the growth factors driving the India Connected Mining Market?

The growth of the India Connected Mining Market is driven by the increasing demand for automation, the need for enhanced safety measures, and the rising focus on operational efficiency. Additionally, the adoption of sustainable mining practices is also contributing to market growth.

What challenges does the India Connected Mining Market face?

Challenges in the India Connected Mining Market include high initial investment costs, the complexity of integrating new technologies with existing systems, and concerns regarding data security and privacy. These factors can hinder the adoption of connected mining solutions.

What opportunities exist in the India Connected Mining Market?

Opportunities in the India Connected Mining Market include the potential for innovation in mining technologies, the expansion of smart mining solutions, and the increasing emphasis on sustainability and environmental compliance. These factors can lead to new business models and partnerships.

What trends are shaping the India Connected Mining Market?

Trends in the India Connected Mining Market include the growing use of automation and robotics, the implementation of predictive maintenance through data analytics, and the rise of digital twins for operational optimization. These trends are transforming traditional mining practices.

India Connected Mining Market

| Segmentation Details | Description |

|---|---|

| Technology | IoT Solutions, Automation Systems, Data Analytics, Cloud Computing |

| Application | Resource Management, Equipment Monitoring, Safety Management, Fleet Management |

| End User | Mining Companies, Equipment Manufacturers, Service Providers, Contractors |

| Deployment | On-Premises, Cloud-Based, Hybrid, Edge Computing |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies for India Connected Mining Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at