Key Market Insights

-

Automation Gains: Over 40% of new HMC installations now include robotic pallet loading or gantry systems, boosting utilization rates above 85%.

-

Hybridization: Adoption of additive-subtractive HMCs is growing at 15% annually, enabling near-net-shape part production and reduced material waste.

-

Connectivity: More than 60% of HMCs shipped in 2024 featured networked controls compatible with MTConnect or OPC UA for real-time monitoring.

-

Energy Efficiency: Next-gen HMCs incorporate regenerative drives and spindle energy-saving modes, cutting power draw by up to 20%.

-

Regional Leadership: Asia-Pacific accounts for approximately 50% of global HMC demand, with rapid capacity additions in China and India.

Market Drivers

-

Industry 4.0 Initiatives: Manufacturers are investing in smart, connected HMCs to enable predictive maintenance and production transparency.

-

Aerospace Expansion: Growth in aircraft deliveries requires high-rigidity HMCs for titanium and aluminum structural parts.

-

Automotive Electrification: EV powertrain components (e-motor housings) demand precision machining, driving HMC purchases.

-

Labor Shortages: Automation of loading, unloading, and part inspection makes HMCs attractive amid skilled-labor scarcity.

-

Lifecycle Upgrades: OEMs are replacing legacy horizontal mills with modern HMCs to improve spindle speed, axis speed, and accuracy.

Market Restraints

-

High Capital Costs: Entry-level HMCs can exceed $200,000, while fully automated cells may top $1 million, limiting adoption among SMEs.

-

Complex Integration: Implementing pallet-handling robots, fixtures, and software requires significant engineering effort and upfront planning.

-

Floor-Space Requirements: HMC cells with multiple pallets and automation can demand large footprints, challenging congested facilities.

-

Maintenance Expertise: Advanced controls and servo systems necessitate specialized technical support and training.

-

Economic Cyclicality: Downturns in key end-use sectors (e.g., automotive) can lead to deferred capital expenditures.

Market Opportunities

-

Modular Automation Kits: Plug-and-play robotic load/unload modules that retrofit existing HMCs can lower automation barriers for tier-2/3 suppliers.

-

Digital Twin Offerings: Virtual commissioning and simulation services for new HMC installations reduce start-up risk and shorten ramp-up time.

-

Additive Integration: Hybrid HMC machines combining directed-energy deposition heads with milling spindles open new part-repair applications.

-

Aftermarket Services: Subscription-based monitoring and remote diagnostics for installed HMC fleets can drive recurring revenues.

-

Emerging‐Market Growth: Rapid manufacturing expansion in Southeast Asia, Latin America, and Eastern Europe creates untapped HMC demand.

Market Dynamics

-

OEM Partnerships: Machine-tool builders collaborate with robotics and software firms to deliver turnkey cells, reducing buyer complexity.

-

Digital Ecosystems: Control manufacturers are partnering with MES/ERP vendors to create seamless data flows from HMCs to production planning.

-

Sustainability Focus: Recycling heat generated by HMC spindles and optimizing coolant flow aligns with corporate environmental targets.

-

Consolidation Trends: Larger OEMs acquiring specialized HMC builders accelerate technology integration and global distribution.

-

Skills Development: Technical schools and industry consortia are launching programs to train operators and programmers on advanced HMC platforms.

Regional Analysis

-

Asia-Pacific: Leader in both consumption and production, fueled by China’s manufacturing modernization plans and India’s automotive growth.

-

North America: Strong demand driven by aerospace, defense, and oil & gas sectors; growing smart-factory initiatives in the U.S. and Canada.

-

Europe: Germany and Italy dominate through precision automotive and die-mold industries; stringent quality standards favor high-end HMCs.

-

Latin America: Emerging investments in light-vehicle OEMs and agricultural-equipment manufacturing spur new HMC installations in Brazil and Mexico.

-

Middle East & Africa: Niche growth for oilfield equipment and defense components; modernization of state-owned enterprises drives selective HMC procurements.

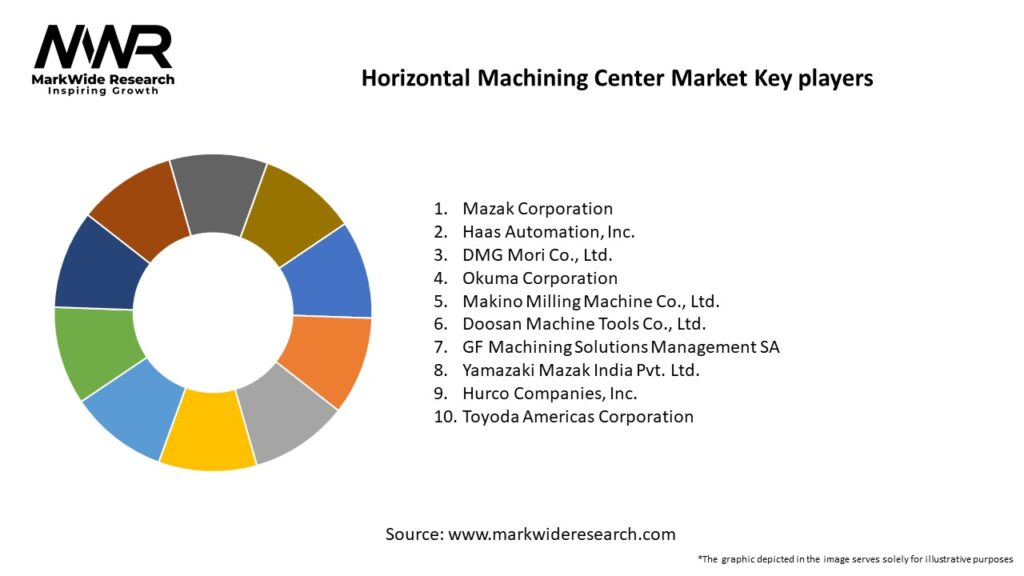

Competitive Landscape

Leading Companies in the Horizontal Machining Center Market:

- Mazak Corporation

- Haas Automation, Inc.

- DMG Mori Co., Ltd.

- Okuma Corporation

- Makino Milling Machine Co., Ltd.

- Doosan Machine Tools Co., Ltd.

- GF Machining Solutions Management SA

- Yamazaki Mazak India Pvt. Ltd.

- Hurco Companies, Inc.

- Toyoda Americas Corporation

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

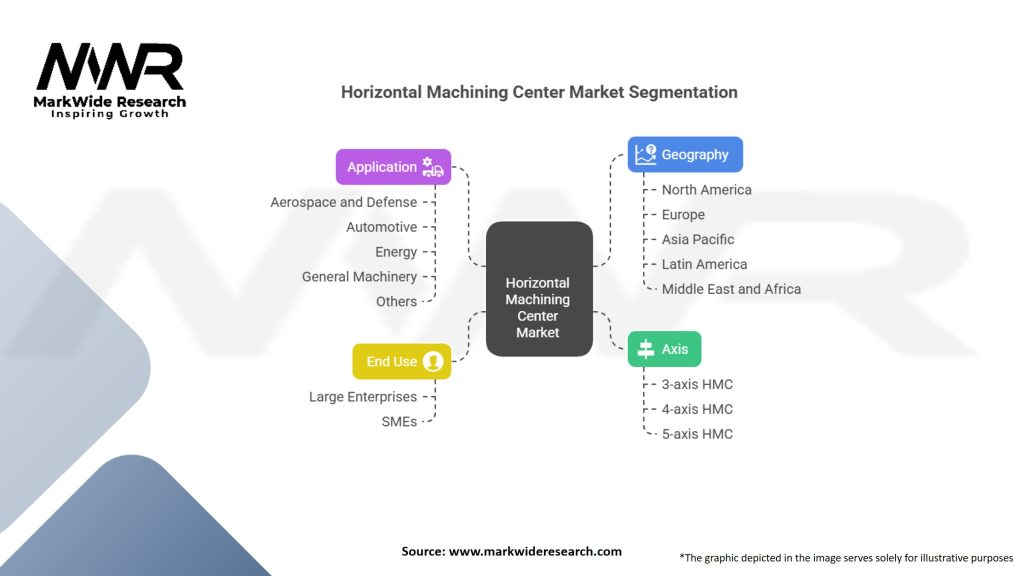

Segmentation

-

By Automation Level: Manual, Partially Automated (Pallet Changer), Fully Automated (Pallet Pool + Robot)

-

By Axis Configuration: 3-Axis, 4-Axis Rotary, 5-Axis Pallet-Turning HMCs

-

By Spindle Power: Low (≤15 kW), Medium (15–30 kW), High (>30 kW)

-

By End-Use Industry: Aerospace, Automotive, Die & Mold, Medical Devices, Energy, General Engineering

-

By Region: Asia-Pacific, North America, Europe, Latin America, Middle East & Africa

Category-wise Insights

-

Compact HMCs: Short-footprint models (e.g., Haas VF-5SSY) suited for small-batch and job-shop environments.

-

Large-Capacity HMCs: Heavy-duty machines (e.g., DMG MORI NHX series) for five-axis processing of large aerospace and mold plates.

-

Hybrid Additive-Subtractive HMCs: Integrated systems (e.g., Mazak INTEGREX i-HYB) that combine DED heads with milling spindles.

-

Multi-Pallet HMCs: Pallet-pool or rotary-storage variants (e.g., Okuma MP series) enabling lights-out, high-volume production.

-

High-Speed HMCs: Specialized models with up to 24,000 rpm spindles for aluminum and composite part machining.

Key Benefits for Industry Participants and Stakeholders

-

Increased Throughput: Pallet changeovers in under 15 seconds and continuous operation maximize cutting time.

-

Consistent Quality: Enhanced chip control and rigid construction deliver tighter tolerances and superior surface finish.

-

Labor Optimization: Automated loading/unloading reduces reliance on skilled operators for simple repetitive tasks.

-

Flexibility: Multi-axis and multi-pallet configurations support a wide range of part sizes and batch quantities.

-

Data-Driven Decisions: Real-time process data from HMCs feed analytics platforms, enabling cycle-time reductions and preventive maintenance.

SWOT Analysis

Strengths:

-

Proven productivity gains and quality improvements in demanding industries.

-

Broad machine portfolios from global OEMs covering all application niches.

-

Strong integration of automation and digital services.

Weaknesses:

-

High upfront investment and integration complexity for fully automated cells.

-

Require skilled technical support for advanced control and robotics systems.

-

Large footprint may not suit constrained shop floors.

Opportunities:

-

Retrofit automation kits for legacy horizontal mills to introduce pallet-handling at lower cost.

-

Expansion of hybrid additive-subtractive HMCs to address prototyping and repair markets.

-

Aftermarket subscription services for digital monitoring, predictive maintenance, and remote support.

Threats:

-

Persistent global supply-chain constraints on semiconductors and precision components.

-

Economic downturns in automotive and aerospace affecting capital-goods budgets.

-

Emerging competition from low-cost machine builders offering simplified horizontals.

Market Key Trends

-

Edge Computing on HMCs: Onboard analytics enabling instantaneous feedback on tool wear, work-offset shifts, and vibration detection.

-

Digital Twin Deployment: Virtual replicas of HMC cells used for process optimization, fixture validation, and operator training.

-

Green Machining Practices: Coolant-through-tool, energy-recovery drives, and high-pressure coolant systems to reduce environmental impact.

-

Collaborative Robots: Use of cobots for part tending and inspection alongside HMCs, minimizing safety-zone requirements.

-

Subscription Financing: As-a-Service models bundling HMC hardware, software updates, and maintenance into a monthly fee.

Covid-19 Impact

The pandemic initially disrupted machine deliveries and integration projects due to travel restrictions. However, pressures to reduce on-site staffing accelerated adoption of automated HMC cells and remote monitoring solutions. Post-pandemic, machine-tool orders rebounded strongly as OEMs sought to reshore production and enhance resilience through lights-out manufacturing capabilities.

Key Industry Developments

-

DMG MORI’s Digital Factory Launch (2023): A cloud-based platform for remote monitoring and optimization of HMC fleets worldwide.

-

Mazak’s SmartBox Integration (2022): Standard inclusion of Yamazaki Mazak SmartBox Automation Cells with many new horizontal mill models.

-

Okuma’s THINC OSP i-Auto Tuning (2024): AI-driven control feature that automatically optimizes feedrates and spindle speeds for cycle-time reduction.

-

Haas Automation’s Robot Integration Kit (RIK) Expansion (2021): New universal mounting interface for collaborative and industrial robots on HMCs.

Analyst Suggestions

-

Invest in Modular Automation: Offer scalable pallet-changer and robot-tending modules that grow with customer needs, lowering the entry barrier.

-

Enhance Service Digitalization: Develop subscription-based monitoring and remote-support services to generate recurring revenue and improve machine uptime.

-

Promote Hybrid Solutions: Educate customers on the benefits of additive-subtractive HMCs for reduced material usage and part-repair capabilities.

-

Target Aftermarket Upgrades: Provide retrofit packages for older horizontal mills to add connectivity, pallet handling, and condition monitoring.

-

Strengthen Training Programs: Partner with vocational schools and OEM training centers to upskill operators and programmers on advanced HMC features.

Future Outlook

The Horizontal Machining Center market is set to sustain strong growth, outpacing general machine-tool markets through 2030. Advancements in automation, digitalization, and hybrid machining will continue to enhance HMC value propositions, making them central to high-mix, medium-volume, and lights-out production strategies. As manufacturers prioritize agility, resilience, and sustainability, HMC suppliers that deliver turnkey, data-driven, and service-oriented solutions will lead the next wave of industrial transformation.

Conclusion

Horizontal Machining Centers have evolved from standalone mills into integral nodes of smart, autonomous manufacturing cells. By combining high-rigidity construction, efficient chip management, and seamless automation & connectivity, modern HMCs deliver the productivity, quality, and flexibility demanded by today’s competitive industries. Stakeholders who embrace modular automation, robust digital ecosystems, and value-added services will secure leadership in a market driven by continual innovation and the relentless pursuit of operational excellence.