444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The high purity grade BISP-TMC market has been experiencing significant growth owing to its increasing demand in various industrial applications. BISP-TMC, or bis(trimethylsilyl)pentamethyldisilazane, is a high purity grade chemical compound used primarily as a silicon source in the production of advanced materials such as semiconductors, photovoltaic cells, and electronic components. Its exceptional purity and chemical properties make it a preferred choice in industries requiring precise and reliable silicon deposition processes.

Meaning

BISP-TMC, or bis(trimethylsilyl)pentamethyldisilazane, is a specialized chemical compound known for its high purity and precise composition. It belongs to the organosilicon family and is primarily used as a silicon source in various industrial applications, particularly in the semiconductor and electronics industries. BISP-TMC is valued for its exceptional purity, which ensures precise silicon deposition processes and high-quality end products.

Executive Summary

The high purity grade BISP-TMC market is witnessing robust growth driven by the increasing demand for advanced materials in semiconductor manufacturing, photovoltaic cell production, and electronic component fabrication. Key factors contributing to market expansion include the growing adoption of high-performance electronic devices, the emergence of new applications in the automotive and aerospace sectors, and the continuous innovation in materials science and nanotechnology.

Key Market Insights

Market Drivers

Several factors are driving the growth of the high purity grade BISP-TMC market:

Market Restraints

Despite the favorable market conditions, the high purity grade BISP-TMC market faces certain challenges:

Market Opportunities

The high purity grade BISP-TMC market presents several opportunities for growth and innovation:

Market Dynamics

The high purity grade BISP-TMC market is characterized by dynamic trends and factors influencing growth and competitiveness:

Regional Analysis

The high purity grade BISP-TMC market is geographically diverse, with key regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. Each region has its unique market dynamics, regulatory environment, and industrial landscape. Asia-Pacific is the largest and fastest-growing market for high purity grade BISP-TMC, driven by the presence of major semiconductor manufacturing hubs in countries such as China, Taiwan, South Korea, and Japan. North America and Europe are mature markets for high purity grade BISP-TMC, characterized by advanced technology adoption, strong R&D capabilities, and stringent quality standards. Latin America and the Middle East and Africa offer growth opportunities for high purity grade BISP-TMC, supported by increasing investments in infrastructure development, industrialization, and technology transfer.

Competitive Landscape

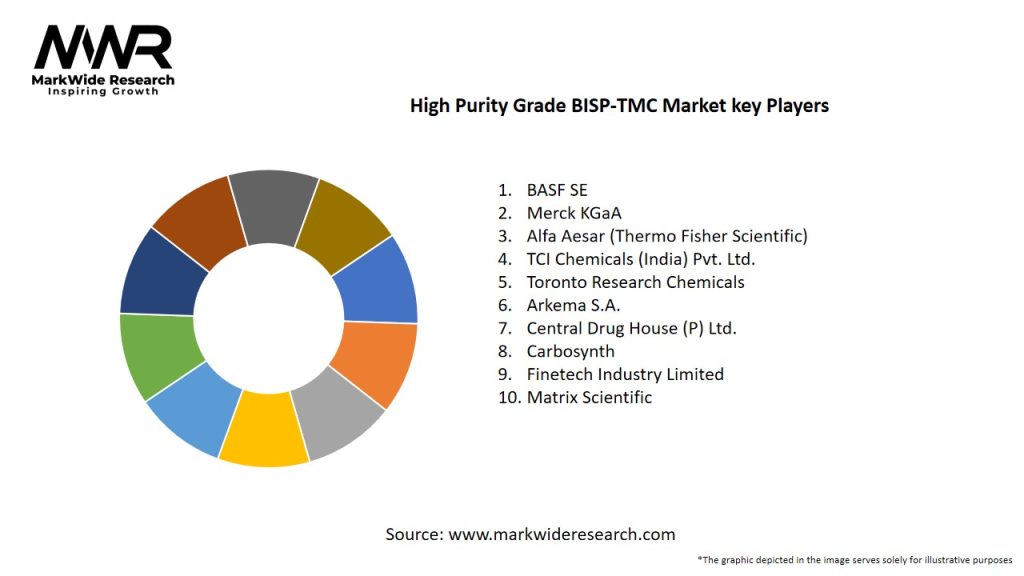

The high purity grade BISP-TMC market is competitive, with several multinational and regional players operating in the industry. Key players include:

These companies compete on factors such as product quality, purity, reliability, technical support, pricing, and customer service. Strategic initiatives such as product launches, acquisitions, partnerships, and investments in research and development are common in the market as players seek to gain a competitive edge and expand their market presence.

Segmentation

The high purity grade BISP-TMC market can be segmented based on various factors, including:

Each segment has unique characteristics, requirements, and growth drivers, offering opportunities for manufacturers and suppliers to target specific market segments and address the evolving needs and preferences of customers and end-users.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The high purity grade BISP-TMC market offers several benefits for industry participants and stakeholders:

SWOT Analysis

Market Key Trends

Several key trends are shaping the high purity grade BISP-TMC market:

Covid-19 Impact

The Covid-19 pandemic has had mixed impacts on the high purity grade BISP-TMC market. While certain segments such as semiconductor manufacturing experienced minimal disruptions, others such as photovoltaic cell production and electronic component fabrication faced significant challenges due to supply chain disruptions, production slowdowns, and reduced demand. However, the pandemic also underscored the importance of digitalization, remote work, and automation in maintaining business continuity and accelerating technology adoption in the semiconductor and electronics industries. As countries and industries recover from the pandemic, opportunities emerge for innovation, collaboration, and investment in advanced materials and manufacturing technologies that drive growth, competitiveness, and sustainability.

Key Industry Developments

Analyst Suggestions

Based on market trends and dynamics, analysts suggest the following strategies for industry participants:

Future Outlook

The high purity grade BISP-TMC market is poised for continued growth and innovation, driven by the increasing demand for advanced materials in semiconductor manufacturing, photovoltaic cell production, and electronic component fabrication. Key trends such as digitalization, automation, sustainability, and collaboration will continue to shape the market landscape and opportunities for industry participants and stakeholders. As countries and industries strive to achieve technological leadership, economic resilience, and environmental sustainability, the demand for high purity grade BISP-TMC and other advanced materials is expected to grow, driving investment and innovation in the global semiconductor and electronics industries.

Conclusion

In conclusion, the high purity grade BISP-TMC market offers significant opportunities for industry participants and stakeholders to address emerging challenges, drive innovation, and promote sustainability in the semiconductor and electronics industries. Despite challenges such as supply chain disruptions, raw material price volatility, and regulatory constraints, high purity grade BISP-TMC remains a critical enabler of advanced materials and manufacturing technologies, supporting the development of high-performance electronic devices and components. By investing in research and development, collaboration, and sustainability initiatives, industry participants can position themselves for success in the dynamic and evolving high purity grade BISP-TMC market, driving growth, competitiveness, and sustainability for years to come.

High Purity Grade BISP-TMC Market

| Segmentation Details | Description |

|---|---|

| Product Type | Solvents, Reagents, Catalysts, Additives |

| Grade | Ultra-Pure, High-Purity, Technical Grade, Analytical Grade |

| Application | Pharmaceuticals, Electronics, Biotechnology, Research |

| End Use Industry | Healthcare, Manufacturing, Agriculture, Others |

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at