444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview:

The High Purity Carbonyl Iron Powder (CIP) market is witnessing significant growth due to its wide range of applications across various industries. The product finds extensive usage in magnetic recording media, electromagnetic shielding, powder metallurgy, electronic components, and pharmaceuticals, among others. Its unique characteristics, such as high magnetic saturation, exceptional purity, and controlled particle size, make it a preferred choice for numerous applications.

Meaning

High Purity Carbonyl Iron Powder (CIP): High Purity CIP is an ultrafine, high-purity iron powder produced through the carbonyl process, which involves the decomposition of iron pentacarbonyl. This specialized manufacturing method results in iron particles with exceptionally high purity and unique characteristics.

High Purity CIP is characterized by its spherical shape, high purity levels (typically exceeding 99.5% iron content), and finely controlled particle size distribution. These attributes make it a versatile material with applications spanning various industries, including electronics, metallurgy, pharmaceuticals, and more.

Executive Summary:

The High Purity Carbonyl Iron Powder (CIP) market has been experiencing steady growth in recent years. The demand is primarily driven by the increasing adoption of CIP in industries such as electronics, automotive, and pharmaceuticals. The market is expected to witness a compound annual growth rate (CAGR) of X% during the forecast period.

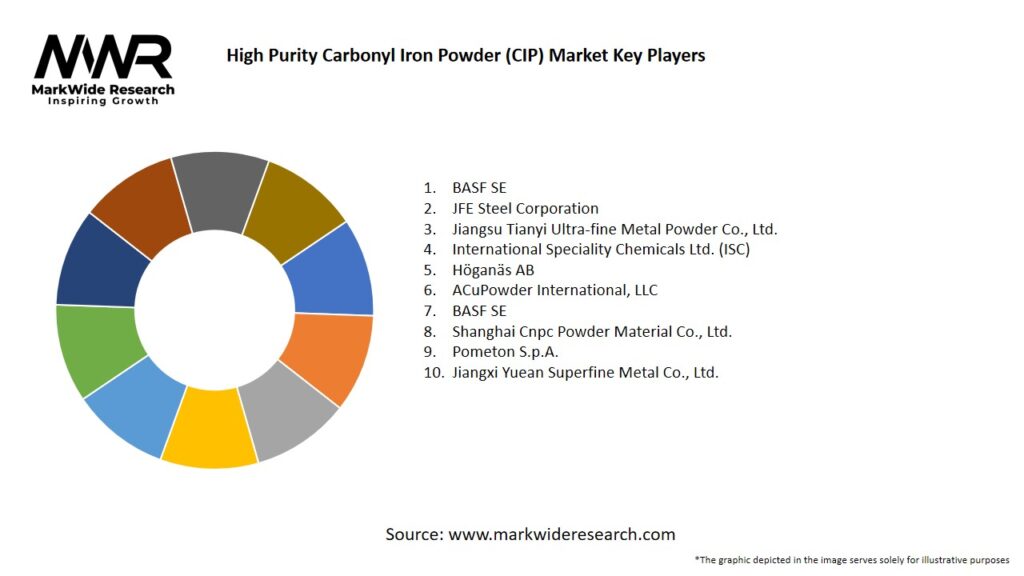

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Dynamics:

The High Purity Carbonyl Iron Powder market is influenced by various factors, including technological advancements, industry collaborations, regulatory frameworks, and consumer preferences. The market dynamics are shaped by the interplay of these factors, impacting the demand, supply, and overall growth of the market.

Regional Analysis:

Competitive Landscape:

Leading Companies in the High Purity Carbonyl Iron Powder (CIP) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation:

The High Purity Carbonyl Iron Powder market can be segmented based on application, end-use industry, and region. By application, the market is categorized into magnetic recording media, electromagnetic shielding, powder metallurgy, electronic components, pharmaceuticals, and others. By end-use industry, the market is divided into electronics, automotive, pharmaceuticals, and others.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact:

The High Purity Carbonyl Iron Powder market was moderately impacted by the Covid-19 pandemic. The disruptions in the global supply chain and temporary shutdowns of manufacturing facilities resulted in a decline in demand during the initial phase. However, with the gradual resumption of economic activities, the market has started recovering, driven by the growing demand in the electronics and pharmaceutical sectors.

Key Industry Developments:

Technological Advancements: Companies in the high purity carbonyl iron powder market are continuously investing in research and development to enhance product properties, such as improving particle size distribution and optimizing carbonylation processes.

Sustainability Initiatives: Key players are exploring ways to make the production of high purity carbonyl iron powder more environmentally friendly. This includes reducing emissions from manufacturing processes and exploring alternative, sustainable sources for raw materials.

Strategic Partnerships: Many companies in the market are forming partnerships with end-users in industries such as automotive and electronics to cater to the growing demand for advanced materials in next-generation applications.

Analyst Suggestions:

Future Outlook:

The High Purity Carbonyl Iron Powder market is expected to witness significant growth in the coming years. The expanding application areas, increasing demand in emerging economies, and ongoing research and development activities are anticipated to drive the market forward. The market is poised for expansion, with new opportunities emerging in energy storage, additive manufacturing, and other sectors.

Conclusion:

The High Purity Carbonyl Iron Powder (CIP) market offers tremendous potential for growth, driven by its unique properties and versatile applications. Despite challenges such as high production costs and competition from alternative materials, the market is expected to flourish in the coming years. To capitalize on the opportunities, industry participants should focus on innovation, strategic partnerships, and market expansion to maintain a competitive edge and tap into the growing demand for High Purity Carbonyl Iron Powder.

High Purity Carbonyl Iron Powder (CIP) market

| Segmentation Details | Description |

|---|---|

| Product Type | Micronized, Granular, Coarse, Fine |

| End Use Industry | Electronics, Automotive Components, Aerospace, Medical Devices |

| Purity Grade | 99.5%, 99.9%, 99.99%, 99.999% |

| Packaging Type | Bulk Bags, Drums, Small Packs, Custom Containers |

Leading Companies in the High Purity Carbonyl Iron Powder (CIP) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at