444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The rice and grain market is a vital segment of the global food industry, catering to the dietary needs of millions of people worldwide. In recent years, there has been a growing demand for safer and more nutritious food products. High Pressure Processing (HPP) has emerged as a revolutionary technology that addresses these concerns by ensuring food safety, extending shelf life, and preserving the nutritional value of rice and grain-based products. This comprehensive guide explores the key aspects of HPP in the rice and grain market, including its meaning, market insights, opportunities, and future outlook.

Meaning

High Pressure Processing (HPP), also known as High Pressure Pasteurization, is a non-thermal food processing technique that uses hydrostatic pressure to inactivate spoilage microorganisms and pathogens present in food products. The process involves subjecting packaged foods, such as rice and grain products, to high levels of hydrostatic pressure, typically between 300 to 600 MPa (Mega Pascals). This high pressure disrupts the cellular structure of microorganisms, effectively killing them and increasing the shelf life of the food without the need for heat or chemical preservatives.

Executive Summary

High Pressure Processing has gained significant attention in the rice and grain market due to its ability to enhance food safety, maintain freshness, and preserve the nutritional quality of these staple food products. This technology offers numerous benefits, including extended shelf life, improved product quality, and reduced need for additives. It has become a preferred choice for manufacturers and consumers seeking safer and healthier food options.

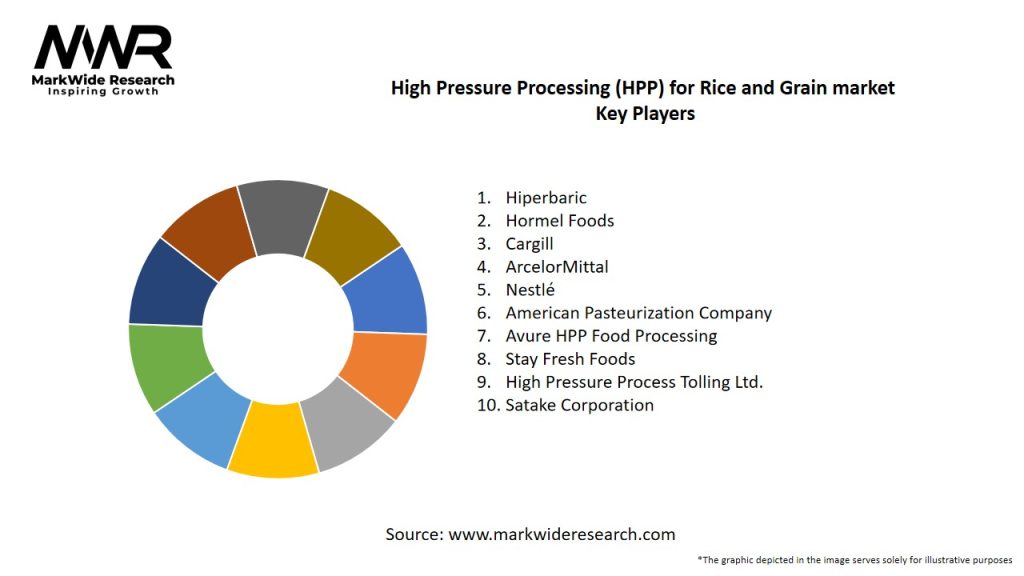

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

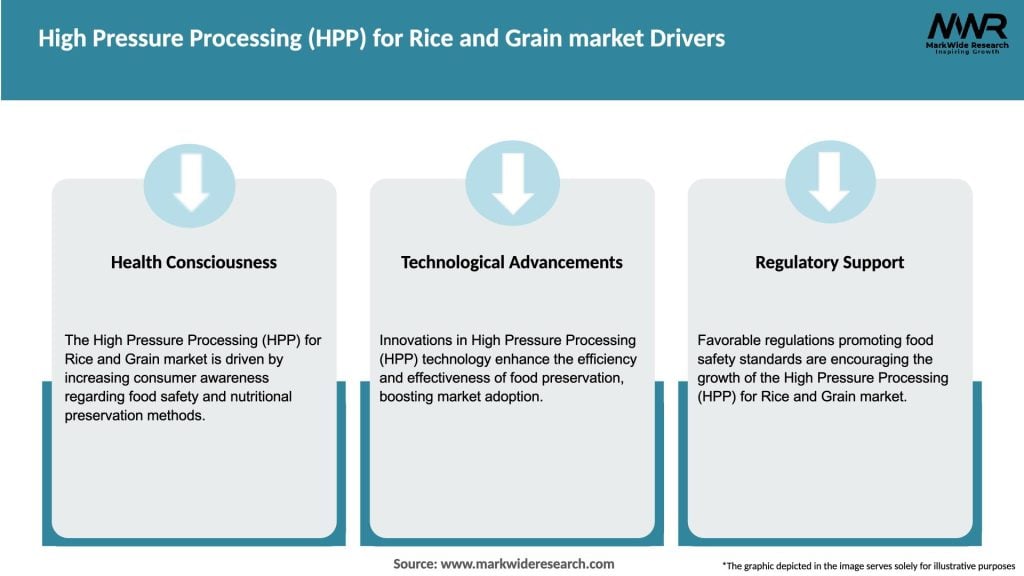

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The rice and grain market is highly dynamic, driven by factors such as consumer preferences, technological advancements, and regulatory frameworks. The adoption of HPP technology in this market is expected to continue its upward trajectory, driven by the need for safer and more nutritious food options. Manufacturers who embrace this technology can gain a competitive edge by offering high-quality, long-lasting products that meet the evolving demands of consumers.

Regional Analysis

The adoption of HPP in the rice and grain market varies across regions. North America and Europe have witnessed significant uptake of HPP technology, driven by stringent food safety regulations and increasing consumer demand for clean label products. Asia Pacific and Latin America are emerging markets for HPP in the rice and grain industry, driven by the rising population, urbanization, and changing dietary patterns.

Competitive Landscape

Leading Companies in the High Pressure Processing (HPP) for Rice and Grain Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

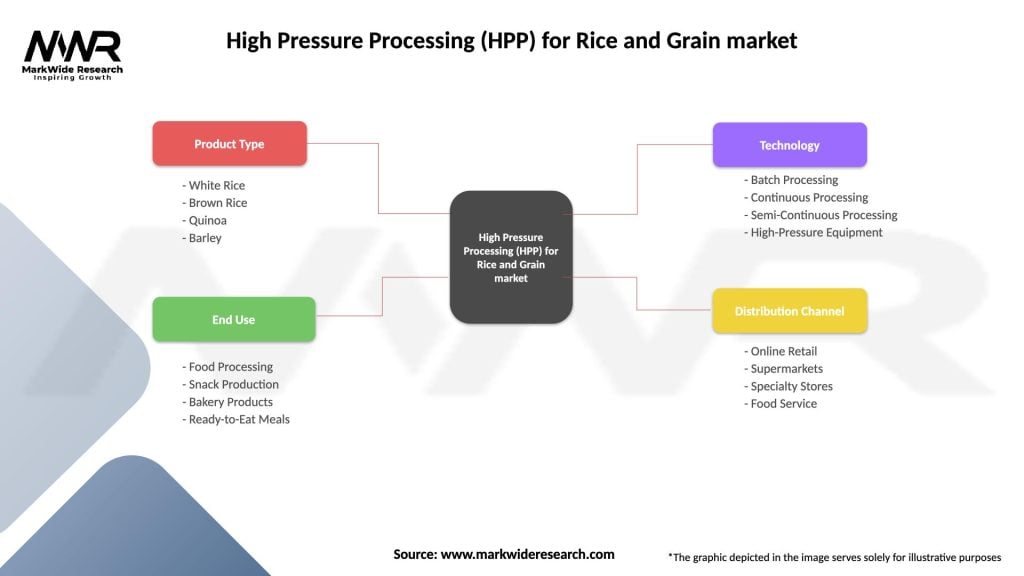

Segmentation

The rice and grain market can be segmented based on product type, end-use applications, and geographical regions. Product types may include white rice, brown rice, basmati rice, parboiled rice, wheat, barley, oats, and more. End-use applications encompass retail, food service, and industrial applications.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has highlighted the importance of food safety and hygiene. Consumers are now more conscious of the safety and quality of the food they consume. HPP technology has gained prominence during the pandemic as a reliable method to ensure food safety and prolong the shelf life of rice and grain products, responding to the increased demand for safer and more sustainable food options.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of HPP in the rice and grain market looks promising, with continued growth expected. Increasing consumer demand for safer and healthier food products, coupled with advancements in HPP technology and equipment, will drive the adoption of HPP in this industry. Manufacturers who embrace this technology and adapt to changing consumer preferences will gain a competitive advantage and capitalize on the evolving market trends.

Conclusion

High Pressure Processing (HPP) has revolutionized the rice and grain market by offering a safe and natural method for enhancing food safety, extending shelf life, and preserving nutritional value. As consumer awareness and demand for safer and healthier food options continue to rise, the adoption of HPP technology is expected to expand further. Manufacturers and industry stakeholders who embrace HPP will be well-positioned to meet consumer expectations, comply with regulatory requirements, and thrive in the evolving rice and grain market landscape.

What is High Pressure Processing (HPP) for Rice and Grain?

High Pressure Processing (HPP) for Rice and Grain refers to a non-thermal food preservation method that uses high pressure to eliminate pathogens and extend shelf life while maintaining the quality and nutritional value of rice and grains.

What are the key companies in the High Pressure Processing (HPP) for Rice and Grain market?

Key companies in the High Pressure Processing (HPP) for Rice and Grain market include Hiperbaric, Avure Technologies, and Kobe Steel, among others.

What are the growth factors driving the High Pressure Processing (HPP) for Rice and Grain market?

The growth of the High Pressure Processing (HPP) for Rice and Grain market is driven by increasing consumer demand for safe and minimally processed foods, the rising popularity of ready-to-eat meals, and the need for longer shelf life in food products.

What challenges does the High Pressure Processing (HPP) for Rice and Grain market face?

Challenges in the High Pressure Processing (HPP) for Rice and Grain market include the high initial investment costs for HPP equipment, the need for specialized training for operators, and potential limitations in processing certain types of grains.

What opportunities exist in the High Pressure Processing (HPP) for Rice and Grain market?

Opportunities in the High Pressure Processing (HPP) for Rice and Grain market include the expansion of HPP technology into new food categories, increasing collaborations between food manufacturers and HPP service providers, and growing interest in sustainable food processing methods.

What trends are shaping the High Pressure Processing (HPP) for Rice and Grain market?

Trends in the High Pressure Processing (HPP) for Rice and Grain market include the development of innovative HPP techniques, the rise of organic and clean-label products, and the increasing focus on food safety and quality assurance.

High Pressure Processing (HPP) for Rice and Grain market

| Segmentation Details | Description |

|---|---|

| Product Type | White Rice, Brown Rice, Quinoa, Barley |

| End Use | Food Processing, Snack Production, Bakery Products, Ready-to-Eat Meals |

| Technology | Batch Processing, Continuous Processing, Semi-Continuous Processing, High-Pressure Equipment |

| Distribution Channel | Online Retail, Supermarkets, Specialty Stores, Food Service |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the High Pressure Processing (HPP) for Rice and Grain Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at