444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The high efficiency low voltage aluminum motors market refers to the segment of the motor industry that focuses on producing electric motors with lower voltage requirements and high energy efficiency. These motors are widely used in industries such as manufacturing, automotive, construction, and HVAC systems. The market is driven by the increasing demand for energy-efficient solutions, stringent regulations on energy consumption, and the need to reduce greenhouse gas emissions.

High efficiency low voltage aluminum motors are electric motors designed to operate at lower voltage levels while maintaining superior energy efficiency. These motors are constructed using lightweight aluminum materials, which contribute to their reduced weight, lower energy consumption, and improved thermal performance. They are known for their ability to convert electrical energy into mechanical energy with minimal losses, resulting in enhanced overall system efficiency

Executive Summary:

The high efficiency low voltage aluminum motors market is experiencing substantial growth, driven by the rising demand for energy-efficient solutions across various industries. These motors offer several advantages, including reduced energy consumption, cost savings, and environmental benefits. The market is highly competitive, with key players focusing on product innovation, strategic partnerships, and mergers and acquisitions to gain a competitive edge. The COVID-19 pandemic has impacted the market, but recovery is expected as industries resume operations and invest in sustainable technologies.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Energy Efficiency Demand: As industries and consumers seek ways to lower energy consumption and reduce costs, the demand for high-efficiency motors is growing. High efficiency low voltage aluminum motors help meet these needs by offering energy-saving solutions.

Material Advantages: Aluminum motors are gaining popularity due to their lighter weight and lower production cost compared to copper-based motors, making them a cost-effective alternative without compromising on efficiency.

Regulatory Pressure: Stringent government regulations and energy efficiency standards are pushing manufacturers to adopt high-efficiency motors to meet compliance requirements and avoid penalties.

Industry Adoption: Key industries such as HVAC, manufacturing, automotive, and small appliances are increasingly adopting high-efficiency aluminum motors due to their cost-effectiveness and performance benefits.

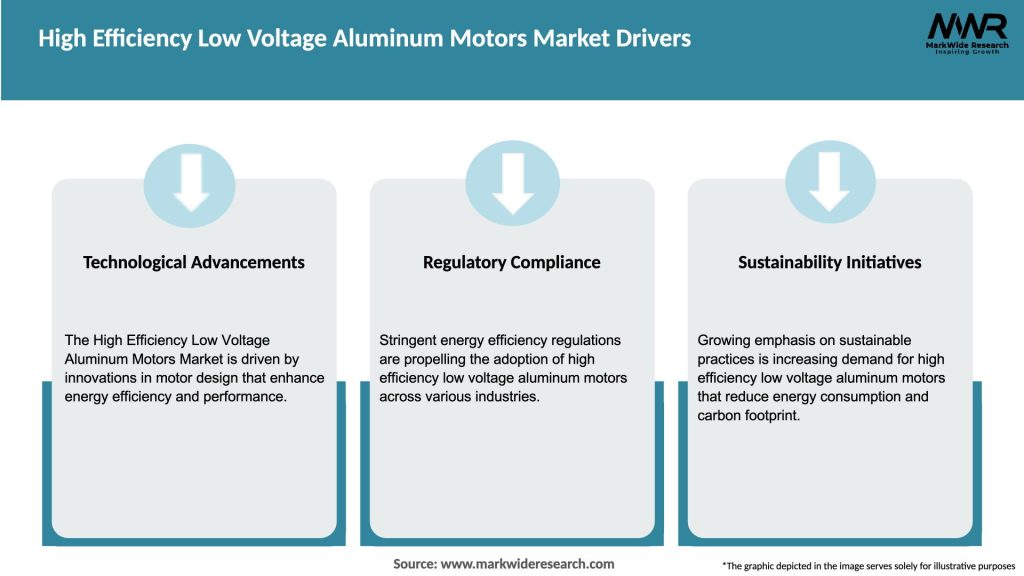

Market Drivers

Several factors are driving the growth of the High Efficiency Low Voltage Aluminum Motors market:

Stringent Energy Efficiency Regulations: Governments around the world are implementing energy efficiency standards and regulations to curb energy consumption and promote environmental sustainability, pushing industries to adopt high-efficiency motors.

Growing Demand for Sustainable Solutions: As environmental concerns rise and sustainability becomes a priority for businesses, industries are turning to energy-efficient technologies like high-efficiency aluminum motors to reduce their carbon footprints.

Technological Advancements in Motor Design: Advancements in materials, design, and motor control systems have improved the efficiency of aluminum motors, making them more attractive for a wide range of applications.

Industrial Automation Growth: The increasing automation in industries such as manufacturing, automotive, and HVAC is driving the demand for energy-efficient motors that can handle continuous operation and contribute to lower operational costs.

Market Restraints

Despite its growth, the High Efficiency Low Voltage Aluminum Motors market faces several challenges:

High Initial Costs: The upfront cost of high-efficiency motors, especially those with advanced technology and design features, can be higher compared to conventional motors, limiting their adoption, particularly in price-sensitive markets.

Technical Challenges: While aluminum motors offer many advantages, their design and production require specialized knowledge, and any errors in manufacturing can affect motor performance and reliability.

Competition from Traditional Motors: Traditional copper-based motors are still widely used due to their established reliability, and their lower initial cost continues to present a challenge to the adoption of high-efficiency aluminum motors.

Market Education and Awareness: In some regions, there is limited awareness regarding the benefits of high-efficiency aluminum motors, which could slow the adoption rate, especially in developing markets.

Market Opportunities

The High Efficiency Low Voltage Aluminum Motors market presents several opportunities for growth:

Rising Demand in Emerging Markets: As industrialization increases in regions such as Asia-Pacific, Latin America, and the Middle East, there is a growing need for energy-efficient motors in various industrial applications, offering significant growth opportunities.

Increasing Adoption in Electric Vehicles: The rise of electric vehicles (EVs) and the adoption of energy-efficient solutions in the automotive sector present a significant opportunity for aluminum motors, which can be used in applications such as electric drivetrains, pumps, and fans.

Smart Grid and IoT Integration: As the integration of IoT and smart grid technology grows, there is an opportunity for high-efficiency motors to be incorporated into connected systems, enabling better energy management and optimization.

Expansion of Renewable Energy Applications: The increasing deployment of renewable energy sources, such as solar and wind, requires highly efficient motors to manage the energy produced. This offers new growth prospects for high-efficiency low voltage aluminum motors.

Market Dynamics

The Global High Efficiency Low Voltage Aluminum Motors market is shaped by several key dynamics:

Technological Advancements: Continuous innovations in motor technology, such as variable frequency drives (VFDs) and energy-saving control systems, are enhancing the efficiency of aluminum motors.

Rising Energy Costs: As global energy prices rise, the need for energy-efficient technologies becomes even more important. High-efficiency motors offer significant long-term savings on electricity costs, driving their adoption across industries.

Environmental Regulations: The enforcement of stricter environmental policies around the world, including standards for energy consumption and emissions, is encouraging the widespread adoption of high-efficiency motors.

Customization and Integration: Manufacturers are increasingly focusing on providing customized motor solutions for specific applications, allowing businesses to tailor their energy-saving solutions for maximum performance and efficiency.

Regional Analysis

The High Efficiency Low Voltage Aluminum Motors market is growing at different rates across regions:

North America: North America holds a significant share of the market due to the presence of stringent energy efficiency regulations, technological advancements, and high demand from industries such as manufacturing, HVAC, and automotive.

Europe: Europe is another key market, driven by strong government policies supporting energy efficiency, renewable energy integration, and eco-friendly technologies.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, a rising focus on energy efficiency, and increased investments in automation across industries such as manufacturing and automotive.

Latin America: The Latin American market is growing as countries in the region focus on upgrading industrial equipment and infrastructure to improve energy efficiency and reduce operational costs.

Middle East & Africa: The market in the Middle East and Africa is expanding due to growing industrial development, energy efficiency mandates, and the adoption of smart technologies in key sectors.

Competitive Landscape

Leading Companies in the High Efficiency Low Voltage Aluminum Motors Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

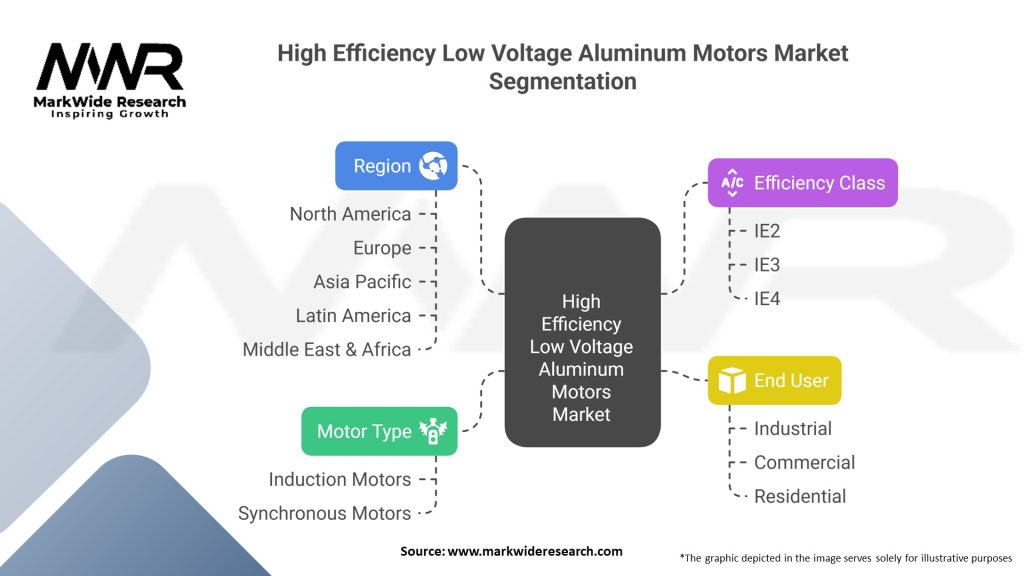

The High Efficiency Low Voltage Aluminum Motors market can be segmented based on:

Type: Asynchronous Motors, Synchronous Motors.

Power Rating: Low Power Motors (Up to 1 HP), Medium Power Motors (1 HP – 10 HP), High Power Motors (Above 10 HP).

End-User Industry: Industrial Equipment, HVAC, Automotive, Renewable Energy, Consumer Appliances.

Category-wise Insights

Asynchronous Motors: These motors are widely used in various low-voltage applications due to their simplicity, reliability, and cost-effectiveness.

Synchronous Motors: Synchronous motors are used in applications requiring precise speed control and are typically more efficient than asynchronous motors, especially in high-demand environments.

Key Benefits for Industry Participants and Stakeholders

The High Efficiency Low Voltage Aluminum Motors market offers several benefits:

Cost Savings: By reducing energy consumption, high-efficiency motors help businesses lower operational costs over the long term.

Sustainability: These motors contribute to sustainability efforts by reducing energy waste and lowering greenhouse gas emissions.

Performance Optimization: High-efficiency motors offer superior performance and reliability, which enhances the overall operational efficiency of industrial equipment.

SWOT Analysis

Strengths:

High energy efficiency and low operational costs.

Lightweight aluminum design reduces material costs.

Weaknesses:

Higher initial purchase cost compared to conventional motors.

Requires advanced manufacturing techniques.

Opportunities:

Growing demand for electric vehicles and automation solutions.

Expanding market in emerging economies.

Threats:

Competition from alternative energy-efficient motor technologies.

Regulatory challenges in certain markets.

Market Key Trends

Key trends influencing the market include:

Increased Adoption of Smart Motors: The integration of IoT technologies into motors for real-time monitoring and performance optimization is a growing trend.

Integration with Renewable Energy: The use of high-efficiency motors in renewable energy applications, such as wind turbines and solar pumps, is expected to increase.

Covid-19 Impact:

The COVID-19 pandemic has had a significant impact on the high efficiency low voltage aluminum motors market. This section assesses the effects of the pandemic on the market, including supply chain disruptions, demand fluctuations, and changes in consumer behavior. It discusses the short-term and long-term implications of the pandemic and the industry’s response to the crisis.

Key Industry Developments:

This section highlights recent industry developments, such as product launches, collaborations, partnerships, and investments. It provides insights into the strategic initiatives undertaken by key players to strengthen their market position, expand their product portfolios, and cater to evolving customer needs. These developments shape the competitive landscape and influence market trends.

Analyst Suggestions:

Based on the comprehensive analysis and market insights, this section provides suggestions and recommendations for industry participants and stakeholders. It offers strategic guidance on market entry, product development, business expansion, and competitive positioning. The suggestions help market players make informed decisions and optimize their operations in the high efficiency low voltage aluminum motors market.

Future Outlook:

The future outlook section provides a glimpse into the anticipated growth trajectory of the high efficiency low voltage aluminum motors market. It forecasts market trends, growth opportunities, and challenges for the coming years. It takes into account factors such as technological advancements, regulatory developments, market demand, and industry dynamics to project the market’s future landscape.

Conclusion:

In conclusion, the high efficiency low voltage aluminum motors market presents significant growth prospects driven by the demand for energy-efficient solutions, regulatory initiatives, and technological advancements. Industry participants and stakeholders need to stay abreast of market dynamics, capitalize on emerging opportunities, and address challenges to thrive in this competitive landscape. With a focus on innovation, sustainability, and customer-centric strategies, the market is poised for robust growth in the future.

What are High Efficiency Low Voltage Aluminum Motors?

High Efficiency Low Voltage Aluminum Motors are electric motors designed to operate at low voltage levels while maximizing energy efficiency. They are commonly used in various applications such as HVAC systems, industrial machinery, and electric vehicles due to their lightweight aluminum construction and high performance.

Who are the key players in the High Efficiency Low Voltage Aluminum Motors Market?

Key players in the High Efficiency Low Voltage Aluminum Motors Market include Siemens, ABB, and Nidec Corporation, among others. These companies are known for their innovative motor technologies and extensive product offerings in the energy-efficient motor segment.

What are the growth factors driving the High Efficiency Low Voltage Aluminum Motors Market?

The growth of the High Efficiency Low Voltage Aluminum Motors Market is driven by increasing demand for energy-efficient solutions, stringent environmental regulations, and the rising adoption of automation in industries such as manufacturing and transportation.

What challenges does the High Efficiency Low Voltage Aluminum Motors Market face?

Challenges in the High Efficiency Low Voltage Aluminum Motors Market include high initial costs of advanced motor technologies and competition from alternative motor types. Additionally, the need for specialized maintenance and technical expertise can hinder market growth.

What opportunities exist in the High Efficiency Low Voltage Aluminum Motors Market?

Opportunities in the High Efficiency Low Voltage Aluminum Motors Market include the growing trend towards renewable energy sources and the increasing focus on sustainability in manufacturing processes. Innovations in motor design and materials also present avenues for market expansion.

What trends are shaping the High Efficiency Low Voltage Aluminum Motors Market?

Trends in the High Efficiency Low Voltage Aluminum Motors Market include the integration of smart technologies for enhanced performance monitoring and control, as well as the development of motors with improved thermal management. Additionally, there is a shift towards modular designs that allow for easier customization and scalability.

High Efficiency Low Voltage Aluminum Motors Market

| Segmentation | Details |

|---|---|

| Motor Type | Induction Motors, Synchronous Motors |

| Efficiency Class | IE2, IE3, IE4 |

| End User | Industrial, Commercial, Residential |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the High Efficiency Low Voltage Aluminum Motors Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at