444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The helicopter blades market plays a vital role in the aviation industry, providing the necessary lift and maneuverability for helicopters to operate effectively. These blades are engineered with precision to withstand the aerodynamic forces and deliver optimum performance. This comprehensive analysis aims to provide valuable insights into the helicopter blades market, including its current state, key trends, drivers, restraints, opportunities, and future outlook.

Meaning

Helicopter blades are an integral part of rotorcraft, responsible for generating lift and controlling the helicopter’s flight. They are typically made of composite materials, such as carbon fiber reinforced polymer or fiberglass, to ensure strength, flexibility, and lightness. The design and construction of helicopter blades require advanced engineering techniques and rigorous testing to ensure safety and performance.

Executive Summary

The helicopter blades market is experiencing steady growth due to the increasing demand for helicopters across various industries, including military, transportation, tourism, and emergency medical services. The market is driven by advancements in technology, such as the use of composite materials, leading to improved efficiency and durability of helicopter blades. However, certain challenges, such as high manufacturing costs and stringent regulatory standards, may hinder market growth.

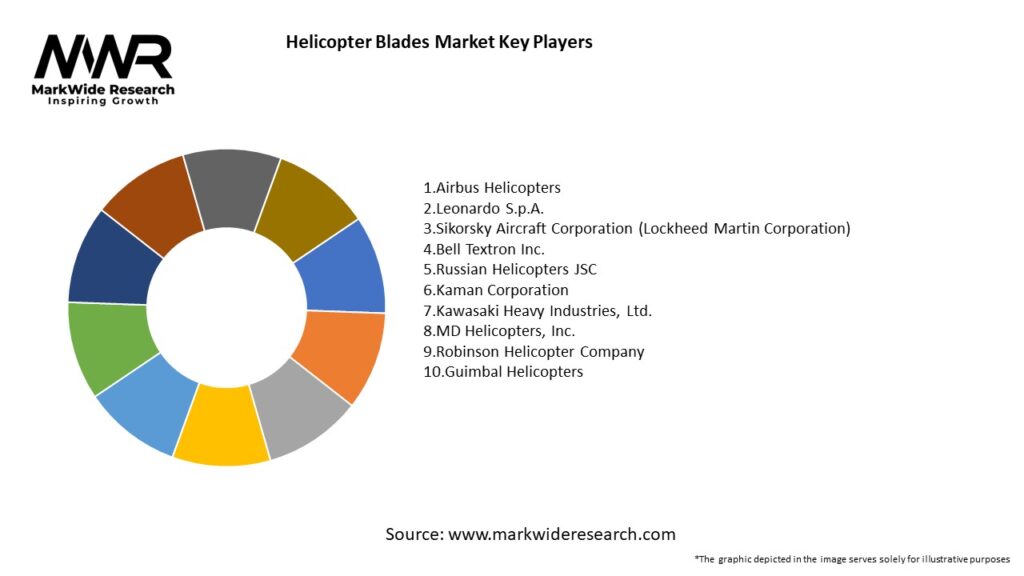

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The helicopter blades market is influenced by various dynamics, including technological advancements, economic factors, regulatory policies, and market competition. Continuous innovation in materials, design, and manufacturing processes is shaping the market landscape. Economic factors, such as GDP growth, defense budgets, and investment in infrastructure, impact the demand for helicopters and, consequently, helicopter blades. Regulatory standards and certifications ensure safety and quality, but they also impose challenges on manufacturers. Competition among market players drives innovation, cost-effectiveness, and customer-centric solutions.

Regional Analysis

The helicopter blades market exhibits regional variations based on factors such as economic development, defense spending, infrastructure requirements, and industry demand. North America and Europe have a mature market due to established aerospace industries and extensive use of helicopters in various applications. Asia Pacific is witnessing significant growth due to rising defense budgets and expanding commercial helicopter services. Latin America, the Middle East, and Africa offer potential opportunities for market players due to increasing investments in infrastructure development and the need for efficient helicopter operations.

Competitive Landscape

Leading Companies in the Helicopter Blades Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

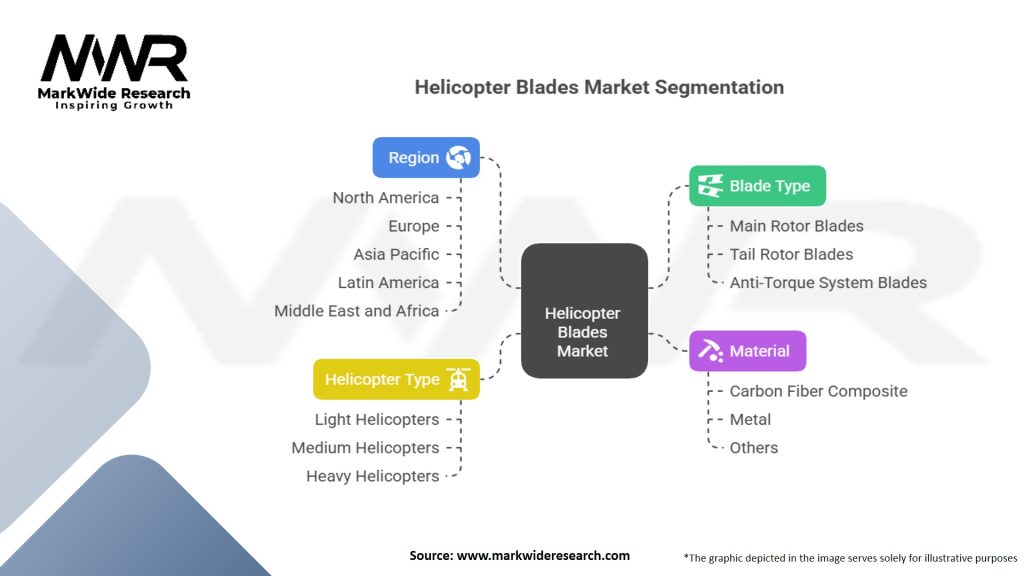

Segmentation

The helicopter blades market can be segmented based on blade type, material, end-user, and region. Blade types include main rotor blades and tail rotor blades. Materials used in helicopter blades comprise composites, metallic alloys, and others. End-users encompass military, commercial, and private sectors.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the helicopter industry, affecting helicopter sales, operations, and aftermarket services. The lockdown measures, travel restrictions, and economic uncertainties led to a temporary decline in demand for helicopters. However, the pandemic also highlighted the importance of helicopters in emergency medical services, supply chain support, and disaster response. As the world recovers from the pandemic, the helicopter blades market is expected to witness gradual recovery and increased demand, driven by resumption of commercial operations, infrastructure development, and defense requirements.

Key Industry Developments

Analyst Suggestions

Future Outlook

The helicopter blades market is expected to grow steadily in the coming years, driven by increasing demand for helicopters across various sectors. Technological advancements, such as the use of composite materials, active blade control systems, and additive manufacturing techniques, will continue to shape the market. Opportunities in urban air mobility, unmanned aerial vehicles, and electric helicopters offer avenues for future growth. However, manufacturers need to address challenges related to manufacturing costs, regulatory compliance, and maintenance to capitalize on market opportunities.

Conclusion

The helicopter blades market is a dynamic and evolving sector within the aviation industry. Advances in technology, growing demand, and emphasis on sustainability are shaping the market landscape. Manufacturers and stakeholders must adapt to changing market dynamics, invest in research and development, collaborate with key players, and embrace sustainability initiatives to stay competitive and drive market growth. The future outlook for the helicopter blades market remains promising, with opportunities in emerging sectors and regions offering untapped potential.

What is Helicopter Blades?

Helicopter blades are the rotating components of a helicopter that generate lift and thrust, allowing the aircraft to fly. They are designed to withstand various aerodynamic forces and are critical for the helicopter’s performance and stability.

What are the key players in the Helicopter Blades Market?

Key players in the Helicopter Blades Market include companies such as Bell Helicopter, Sikorsky Aircraft, Airbus Helicopters, and Leonardo S.p.A., among others. These companies are known for their innovative designs and advanced manufacturing techniques in helicopter blade technology.

What are the growth factors driving the Helicopter Blades Market?

The Helicopter Blades Market is driven by factors such as increasing demand for air mobility solutions, advancements in composite materials for blade manufacturing, and the growing use of helicopters in emergency medical services and search and rescue operations.

What challenges does the Helicopter Blades Market face?

The Helicopter Blades Market faces challenges such as high manufacturing costs, stringent regulatory requirements, and the need for regular maintenance and inspections to ensure safety and performance. These factors can impact the overall market growth.

What opportunities exist in the Helicopter Blades Market?

Opportunities in the Helicopter Blades Market include the development of more efficient and lightweight blade designs, the integration of smart technologies for performance monitoring, and the expansion of helicopter applications in urban air mobility and tourism sectors.

What trends are shaping the Helicopter Blades Market?

Trends in the Helicopter Blades Market include the increasing use of advanced materials such as carbon fiber, the shift towards electric and hybrid propulsion systems, and the focus on noise reduction technologies to enhance urban operations.

Helicopter Blades Market

| Segmentation Details | Description |

|---|---|

| Blade Type | Main Rotor Blades, Tail Rotor Blades, Anti-Torque System Blades |

| Material | Carbon Fiber Composite, Metal, Others |

| Helicopter Type | Light Helicopters, Medium Helicopters, Heavy Helicopters |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Helicopter Blades Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at