444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The heat treatment programmers market is an integral part of the industrial sector, providing essential equipment and solutions for heat treatment processes in various industries. Heat treatment plays a critical role in enhancing the mechanical properties, durability, and performance of metal components and materials used in manufacturing, construction, automotive, aerospace, and other sectors. Heat treatment programmers are specialized devices that control and monitor the heating, cooling, and processing parameters during heat treatment operations, ensuring precise and consistent results.

Meaning

Heat treatment programmers are advanced control systems designed to automate and optimize heat treatment processes. These systems utilize sophisticated algorithms, sensors, actuators, and software interfaces to regulate temperatures, heating rates, holding times, cooling rates, and other parameters critical to achieving desired material properties. Heat treatment programmers are used in furnaces, ovens, kilns, and other heat treatment equipment to achieve uniform heating, quenching, annealing, tempering, and surface hardening of metal components.

Executive Summary

The heat treatment programmers market has witnessed significant growth due to the increasing demand for high-quality, reliable, and efficient heat treatment solutions across industries. The market offers a wide range of heat treatment programmers with varying capabilities, functionalities, and automation levels to meet diverse application requirements. Key market players focus on innovation, customization, and integration of advanced technologies to enhance the performance, accuracy, and productivity of heat treatment processes.

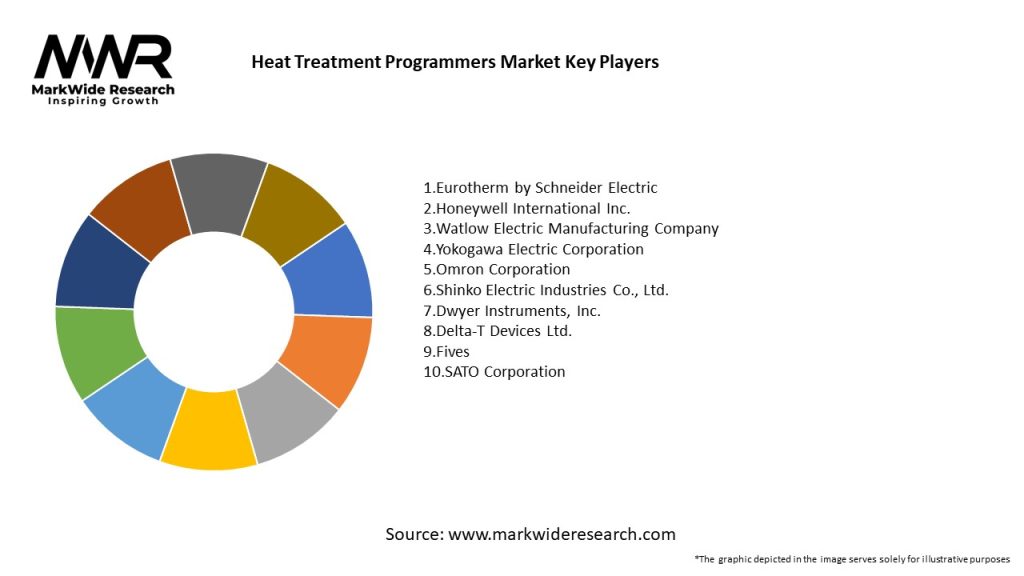

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The heat treatment programmers market operates in a dynamic environment shaped by technological advancements, industry trends, competitive landscape, customer preferences, and regulatory changes. Key dynamics influencing the market include:

Regional Analysis

The heat treatment programmers market exhibits regional variations, industry-specific demands, regulatory frameworks, and market dynamics across key regions:

treatment programmers due to industrial expansion, infrastructure development, automotive production growth, electronics manufacturing, and rising demand for precision engineering solutions. Investments in smart factories, digital transformation, and technology adoption fuel market growth in countries like China, India, Japan, South Korea, and ASEAN nations.

Competitive Landscape

Leading Companies in the Heat Treatment Programmers Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The heat treatment programmers market can be segmented based on:

Category-wise Insight

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic had mixed effects on the heat treatment programmers market:

Key Industry Developments

Analyst Suggestions

Future Outlook

The heat treatment programmers market is poised for growth and transformation:

Conclusion

The heat treatment programmers market plays a vital role in enhancing material properties, mechanical performance, and product quality across industries. With a focus on innovation, customization, digital transformation, and sustainability, industry participants can navigate challenges, capitalize on opportunities, and contribute to the growth, efficiency, and environmental responsibility of heat treatment processes. By leveraging Industry 4.0 technologies, digital integration, and market insights, the heat treatment programmers market continues to evolve, innovate, and deliver value-added solutions to customers worldwide.

What is Heat Treatment Programmers?

Heat Treatment Programmers are specialized software or systems used to control the heat treatment processes of materials, ensuring precise temperature management and timing to achieve desired material properties. They are essential in industries such as metallurgy, manufacturing, and aerospace.

What are the key players in the Heat Treatment Programmers Market?

Key players in the Heat Treatment Programmers Market include companies like Honeywell, Siemens, and Inductotherm, which provide advanced solutions for heat treatment processes. These companies focus on innovation and efficiency in thermal processing technologies, among others.

What are the growth factors driving the Heat Treatment Programmers Market?

The Heat Treatment Programmers Market is driven by the increasing demand for high-performance materials in industries such as automotive and aerospace, as well as the need for energy-efficient manufacturing processes. Additionally, advancements in automation and Industry Four Point Zero technologies are contributing to market growth.

What challenges does the Heat Treatment Programmers Market face?

Challenges in the Heat Treatment Programmers Market include the high initial investment costs for advanced systems and the need for skilled personnel to operate these technologies. Furthermore, the rapid pace of technological change can make it difficult for companies to keep up with the latest advancements.

What opportunities exist in the Heat Treatment Programmers Market?

Opportunities in the Heat Treatment Programmers Market include the growing trend towards automation and smart manufacturing, which can enhance process efficiency and reduce operational costs. Additionally, the increasing focus on sustainability and eco-friendly practices presents avenues for innovation in heat treatment technologies.

What trends are shaping the Heat Treatment Programmers Market?

Trends in the Heat Treatment Programmers Market include the integration of IoT technologies for real-time monitoring and control, as well as the development of software solutions that enhance data analytics capabilities. These trends are helping manufacturers optimize their heat treatment processes and improve product quality.

Heat Treatment Programmers Market

| Segmentation Details | Description |

|---|---|

| Product Type | Furnaces, Ovens, Quench Tanks, Control Systems |

| End User | Aerospace, Automotive, Manufacturing, Tooling |

| Technology | Induction Heating, Resistance Heating, Flame Heating, Microwave Heating |

| Application | Hardening, Annealing, Tempering, Stress Relieving |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Heat Treatment Programmers Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at