Segmentation

-

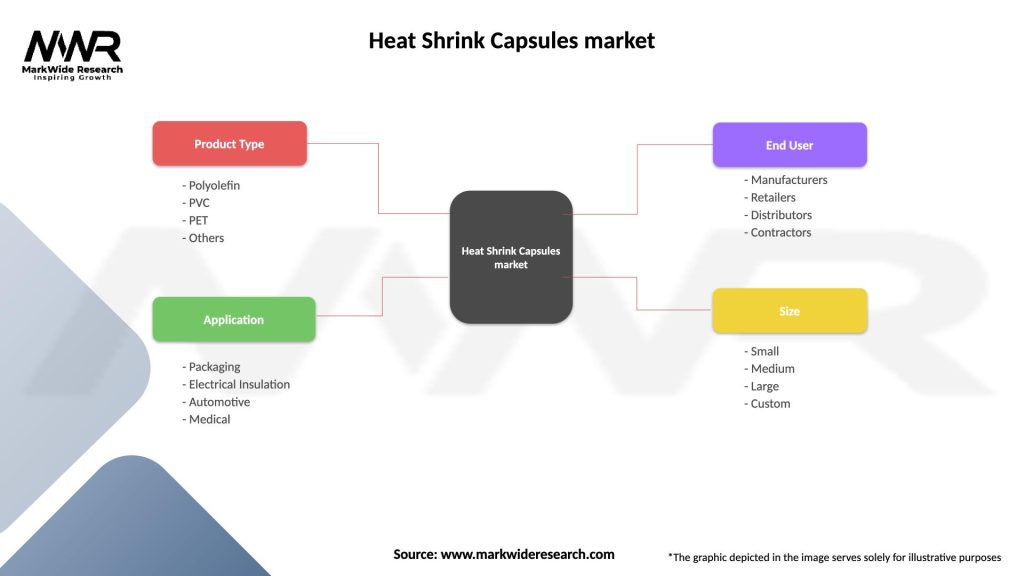

By Material Type:

-

PVC Capsules

-

PETG / Polylaminate & Lightweight

-

Aluminum Foil-Lined

-

Biodegradable / Compostable Options

-

-

By Application Sector:

-

Wine

-

Spirits

-

Olive Oil / Gourmet Foods

-

Cosmetics / Perfume

-

Pharmaceuticals / Nutraceuticals

-

-

By Holder Size:

-

Standard Bottles (750 ml)

-

Small Bottles / Large Formats

-

Minis / Sample Sizes

-

-

By Type of Service:

-

Standard Color Capsules

-

Custom Printed or Embossed

-

Limited Edition Runs

-

Category-wise Insights

-

PVC Capsules: Cost-effective and widely used; may face future environmental scrutiny.

-

Polylaminate / Lightweight Capsules: Balances durability and environmental efficiency.

-

Foil-Lined Capsules: Offer barrier benefits and premium metallic finishes; favored in spirits.

-

Biodegradable Capsules: High potential for brands targeting zero-waste or premium ecologically aligned markets.

-

Custom Embossed Capsules: High impact for luxury brands, but higher cost and setup requirements.

Key Benefits for Industry Participants and Stakeholders

-

Enhanced Shelf Appeal: Capsules complete premium packaging aesthetics, attracting consumer attention.

-

Tamper Evidence: Reassures buyers in retail and e-commerce channels.

-

Brand Differentiation: Allows distinct color, finish, and texture to reinforce identity.

-

Product Protection: Shields closure from dust, weather, and minor damage.

-

Regulatory Compliance: Supports legally required tamper-evident requirements in some regions.

SWOT Analysis

Strengths:

-

Strong brand recognition value; little disruption to core bottling process.

-

Wide material options to suit cost, appearance, and regulatory needs.

Weaknesses:

-

Dependency on heat-shrinking equipment and energy.

-

Environmental scrutiny of single-use plastic materials.

Opportunities:

-

Development of eco-friendly or compostable materials.

-

Digital branding integration (NFC, QR, batch data).

-

Partnerships with craft or limited-edition producers.

Threats:

-

Strict regulations or bans on PVC or non-recyclable materials.

-

Alternative tamper solutions reducing reliance on capsules.

-

Container-free packaging innovations (wax seals, custom caps) in niche sectors.

Market Key Trends

-

Eco-Materials Adoption: Growing materials science focus on compostable or paper-based shrink tubing.

-

Digital Integration: Embedding QR codes or authenticity data in capsule sleeves.

-

Ultra-Lightweight Capsule Designs: Reducing packaging weight while maintaining aesthetics.

-

Short Run Customization Services: Small brands demand uniquely designed capsules with low MOQ.

-

Capsule Return & Recycling Pilots: Some wineries testing collection of capsule waste for reuse or recycling.

Key Industry Developments

-

Bioplastic Capsule Launches: Producers introducing PLA- or paper-based shrink capsules alongside traditional ones.

-

Equipment Upgrades: Shrink machines with adjustable heat and speed control support diverse materials.

-

Limited Edition Capsule Series: Beverage brands launching capsule-only variant programs for seasonal marketing.

-

Digital Authentication Trials: Capsules being used to host QR-enabled traceability or provenance data.

-

Lightweight Capsule Campaigns: Industry moves aiming to reduce average capsule material by 20–30%.

Analyst Suggestions

-

Invest in Green Materials R&D: Capsule suppliers should diversify into compostable or recycled-content sheets.

-

Target Small Brands: Offer short run, fully customizable capsules to attract premium craft producers.

-

Integrate Digital Features: Build NFC, QR, or batch-code capability into capsule designs for marketing and anti-counterfeit strategies.

-

Collaborate with Equipment Manufacturers: Joint development of settings tuned for new materials or finishes can ease adoption.

-

Promote Capsule Recycling: Work with brands to establish collection initiatives, reducing environmental concerns.

Future Outlook

The Heat Shrink Capsules Market will remain essential in premium beverage, cosmetics, and pharmaceutical packaging. Sustainability pressures will drive materials innovation, making lightweight, recyclable, and biodegradable capsules a standard. Digital features will enhance value, turning capsules into interactive touchpoints. Small-batch customization will grow with craft and limited edition trends. Capsule recycling initiatives may further elevate environmental performance and brand alignment with circular economy principles.

Conclusion

The Heat Shrink Capsules Market occupies a strategic niche at the intersection of aesthetics, branding, and packaging integrity. While the legacy PVC capsule remains common, the future lies in eco-sensitive materials, digital branding, and design flexibility for small producers. Brands and manufacturers that proactively adopt sustainable materials, integrate technology, and prioritize customization will lead the market toward greener, smarter packaging solutions.