444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview:

Grouting materials play a crucial role in various industries, including construction, mining, and oil and gas. These materials are used to fill gaps and reinforce structures, providing stability and durability. The grouting materials market has witnessed significant growth in recent years, driven by the increasing demand for infrastructure development and renovation projects worldwide. This comprehensive market analysis aims to provide insights into the key factors influencing the grouting materials market, along with regional analysis, competitive landscape, and future outlook.

Meaning:

Grouting materials refer to cementitious or resin-based compounds used to fill voids and gaps, often in construction projects. These materials are injected into cavities, ensuring structural integrity and preventing the movement of fluids. Grouting materials offer high compressive strength, low shrinkage, and excellent adhesion properties, making them suitable for a wide range of applications.

Executive Summary:

The grouting materials market has experienced steady growth in recent years, driven by the rising construction activities, infrastructure development, and increasing awareness about the importance of structural stability. The market is characterized by the presence of both global and regional players, each striving to gain a competitive edge through product innovation and strategic partnerships. This report provides a comprehensive analysis of the market, including key trends, market drivers, restraints, opportunities, and future outlook.

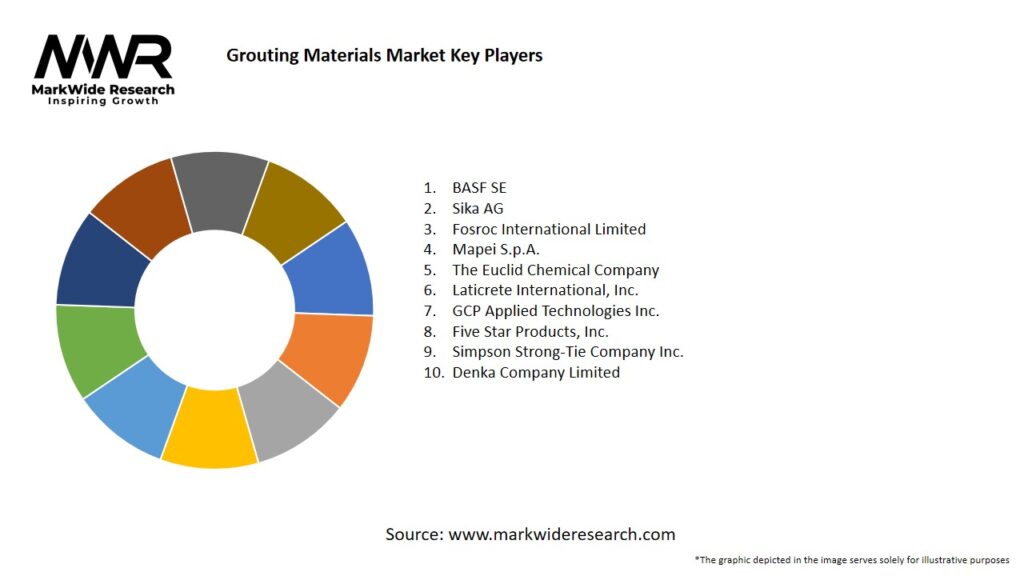

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Cementitious grout remains volume-dominant, especially in general building, tiling, and infrastructure.

Chemical grouts—epoxy, polyurethane, acrylate—are vital for leakage prevention, anchoring, and soil stabilization in complex projects.

Rapid urban infrastructure upgrades worldwide spur demand for high-performance, quick-setting grouts.

Sustainability concerns are lifting interest in low-emission and eco-alternatives to conventional resin-bound grouts.

Increasing adoption of mechanized mixing and injection equipment improves precision, quality, and safety in grouting operations.

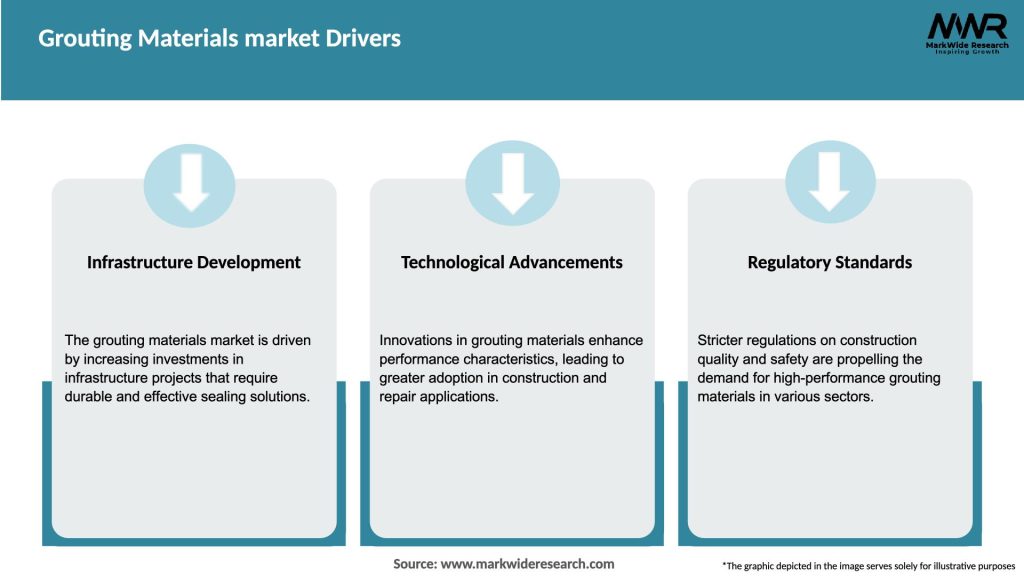

Market Drivers

Infrastructure Renovation & Maintenance: Aging bridges, tunnels, dams, and underground systems require grouting for structural repair and sealing.

New Construction Growth: Urban expansion, high-rise buildings, subway systems, and mining operations demand soil stabilization and anchoring solutions.

Performance Requirements: Projects needing fast curing, chemical resistance, or high strength drive chemical grout adoption.

Technological Advances: Premeasured kits, low-VOC resins, and IoT-enabled delivery systems increase ease of use and safety.

Regulatory Compliance: Growing focus on structural safety and leak prevention mandates efficient grouting in water and wastewater infrastructure.

Market Restraints

Volatile Raw Material Prices: Cement and specialty resins experience price swings that challenge cost predictability.

Application Skill Barriers: Specialized chemical grouts require trained crews to ensure safety and performance.

Regulatory Limits: VOC emissions, resin toxicology, and environmental licensing can restrict certain grout types.

Project Budget Constraints: Chemical grouts often carry higher unit costs, limiting adoption in cost-sensitive projects.

Handling and Storage Requirements: Some grout types have limited shelf life or require extreme storage conditions (temperature, humidity control).

Market Opportunities

Eco-Friendly Formulations: Development of low-VOC, non-toxic, and geopolymer-based or bio-based grouts that support sustainability goals.

Rapid Repair Systems: Grouts with fast-setting and high-strength properties for emergency infrastructure repair or flood control.

Smart, Sensor-Embedded Grouts: New formulations containing sensors for real-time monitoring of structure health and grout performance.

Modular Mixing Equipment: Portable, automated mixing and dispensing units that ensure accurate ratios and reduce waste on-site.

Expansion into Emerging Economies: Infrastructure development in Asia-Pacific, Africa, and Latin America opens new markets for diverse grouting needs.

Market Dynamics

Supply-Side Factors:

Large chemical manufacturers provide standardized chemical grouts, whereas cement producers focus on cost-effective volume products.

Innovation occurs via joint development between specialty chemical firms and construction companies.

Distribution networks span industrial supply houses and regional distributors aligning to local needs and regulations.

Demand-Side Factors:

Constructions firms prioritize ease of application, curing time, structural performance, and cost-effectiveness.

Infrastructure contractors and owners value long-term durability, low-maintenance materials, and risk reduction in grouting systems.

Economic & Policy Factors:

Government infrastructure stimulus, especially post-renewal budgets, boosts mid/high-performance grouting demand.

Environmental regulations push for safer, less toxic grout materials and responsible construction practices.

Regional Analysis

North America & Europe: High uptake of chemical grouts for critical infrastructure repair, tunneling, and building retrofit markets.

Asia-Pacific: Rapid urbanization drives large volumes of cementitious grouts; megaprojects in rail and metro boost chemical grout adoption.

Middle East & Africa: Industrial construction, oil & gas, and mining operations use grouting extensively for anchoring and foundation stabilization.

Latin America: Growing road, energy, and building infrastructure projects increase demand across both standard and specialty grout segments.

Competitive Landscape:

Leading Companies in the Grouting Materials Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

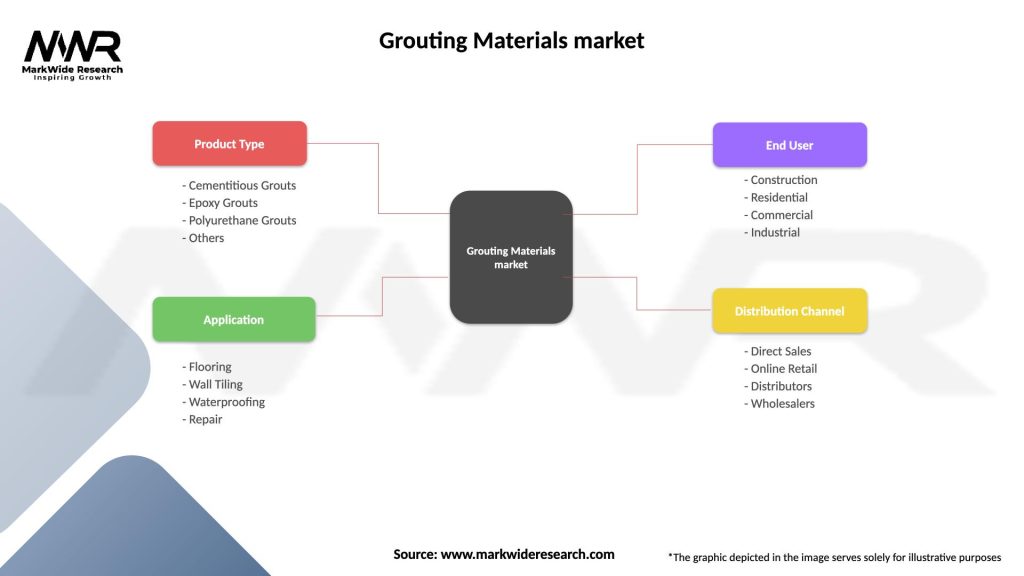

Segmentation

By Product Type:

Cementitious Grouts (standard, polymer-modified)

Epoxy Grouts

Polyurethane Grouts

Acrylate / Acrylic Grouts

Specialty Grouts (silicate, silica fume blends, etc.)

By Application:

Structural Grouting (foundations, anchors)

Waterproofing & Leak Sealing

Soil Stabilization

Tile, Stone, and Masonry Fill

Industrial Equipment Bonding

By End Use Industry:

Infrastructure & Civil Engineering

Building & Construction

Mining & Tunneling

Oil & Gas / Energy

Industrial Manufacturing & Maintenance

By Geography:

North America

Europe

Asia-Pacific

Middle East & Africa

Latin America

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact:

The grouting materials market, like many other industries, experienced disruptions due to the COVID-19 pandemic. The temporary shutdown of construction projects, supply chain disruptions, and economic uncertainties impacted market growth. However, the gradual resumption of construction activities and government stimulus packages to boost infrastructure development are expected to drive market recovery.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The grouting materials market is poised for steady growth in the coming years, driven by ongoing infrastructure development projects, urbanization, and the need for sustainable construction practices. Technological advancements, such asthe development of self-healing and intelligent grouting materials, are expected to shape the market’s future. The increasing focus on environmental sustainability will drive the demand for eco-friendly grouting materials, while the integration of IoT and smart technologies will enable real-time monitoring and control of grouting systems. Additionally, the recovery of the construction industry post-Covid-19 and the growing investments in infrastructure development across regions will provide lucrative opportunities for market players.

Conclusion:

The grouting materials market plays a vital role in ensuring structural stability, durability, and leak prevention in various industries. The market is driven by the increasing demand for infrastructure development, renovation projects, and the emphasis on sustainable construction practices. Key trends, such as the adoption of eco-friendly materials and advancements in self-healing and intelligent grouting, will shape the market’s future. Manufacturers, contractors, engineers, and architects must stay updated with industry dynamics, invest in research and development, and focus on innovation to capitalize on emerging opportunities in this dynamic market.

What is Grouting Materials?

Grouting materials are substances used to fill gaps, voids, or spaces in construction and civil engineering applications. They are essential for providing structural integrity, waterproofing, and load transfer in various projects, including masonry, tile installation, and concrete repairs.

What are the key players in the Grouting Materials market?

Key players in the Grouting Materials market include Sika AG, BASF SE, and Mapei S.p.A., which are known for their innovative products and solutions in construction. These companies focus on developing high-performance grouting materials for various applications, among others.

What are the main drivers of the Grouting Materials market?

The main drivers of the Grouting Materials market include the increasing demand for construction activities, the need for durable and efficient building materials, and the growth of infrastructure projects. Additionally, advancements in technology are leading to the development of more effective grouting solutions.

What challenges does the Grouting Materials market face?

The Grouting Materials market faces challenges such as fluctuating raw material prices and stringent regulations regarding environmental impact. Additionally, the need for skilled labor in application processes can hinder market growth.

What opportunities exist in the Grouting Materials market?

Opportunities in the Grouting Materials market include the rising trend of sustainable construction practices and the increasing adoption of advanced materials. The growing focus on infrastructure development in emerging economies also presents significant growth potential.

What trends are shaping the Grouting Materials market?

Trends shaping the Grouting Materials market include the development of eco-friendly and high-performance grouts, as well as the integration of smart technologies in construction. Additionally, there is a growing emphasis on customization to meet specific project requirements.

Grouting Materials market

| Segmentation Details | Description |

|---|---|

| Product Type | Cementitious Grouts, Epoxy Grouts, Polyurethane Grouts, Others |

| Application | Flooring, Wall Tiling, Waterproofing, Repair |

| End User | Construction, Residential, Commercial, Industrial |

| Distribution Channel | Direct Sales, Online Retail, Distributors, Wholesalers |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Grouting Materials Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at