444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The global starch recovery systems market has been experiencing significant growth in recent years. Starch recovery systems are designed to recover starch from various sources, such as wastewater generated by starch processing industries. These systems help in reducing environmental pollution and minimizing wastage, making them increasingly popular in the food and beverage industry. The market for starch recovery systems is driven by the growing demand for sustainable and eco-friendly solutions across industries.

Starch recovery systems refer to the equipment and processes used to extract starch from different sources and recover it for further use. These systems typically involve the separation of starch from other components, such as fiber, protein, and water, through a series of physical and chemical processes. The recovered starch can then be utilized in various applications, including food processing, paper manufacturing, and biofuel production.

Executive Summary

The executive summary provides a concise overview of the global starch recovery systems market. It highlights the key market trends, growth drivers, and challenges faced by industry participants. The executive summary also provides a glimpse into the regional analysis, competitive landscape, and future outlook of the market.

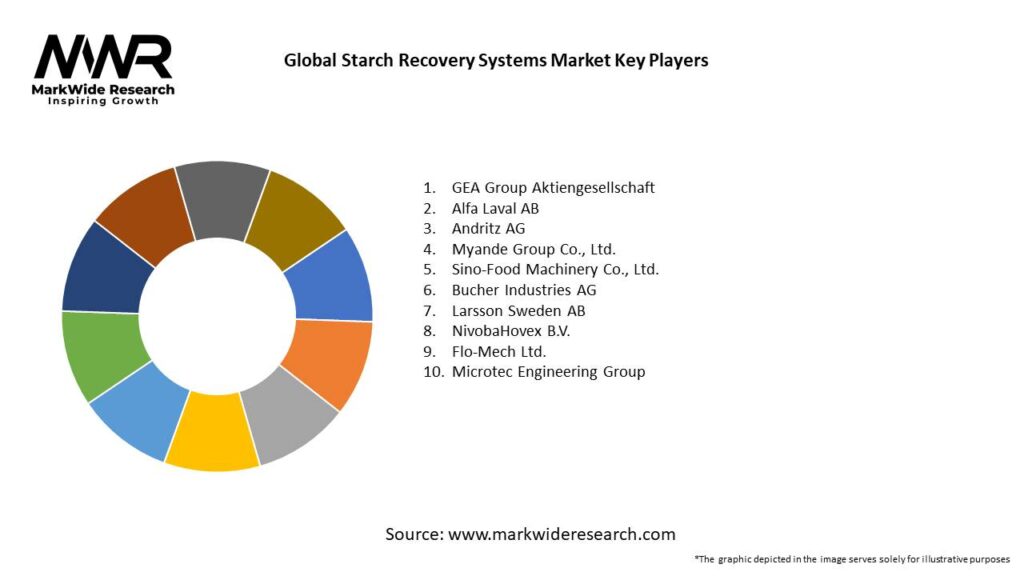

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Regulatory Pressure: Stricter effluent discharge standards (BOD, COD, TSS limits) drive starch plant operators to install recovery systems to pre-treat wastewater.

Cost Savings: Reclaimed starch replacing up to 5–10% of virgin raw materials can yield significant savings, helping offset system investment within 2–4 years.

Water Reuse: In addition to starch recovery, high-efficiency systems enable up to 50% of process water to be recycled, cutting freshwater consumption and treatment costs.

Technology Trends: Integration of Industry 4.0—sensors, SCADA, and AI-based process controls—improves system uptime and reduces energy consumption by up to 15%.

Diverse Applications: Beyond food-grade starch, recovered material finds use in animal feed, biodegradable packaging, adhesives, and fermentation substrates.

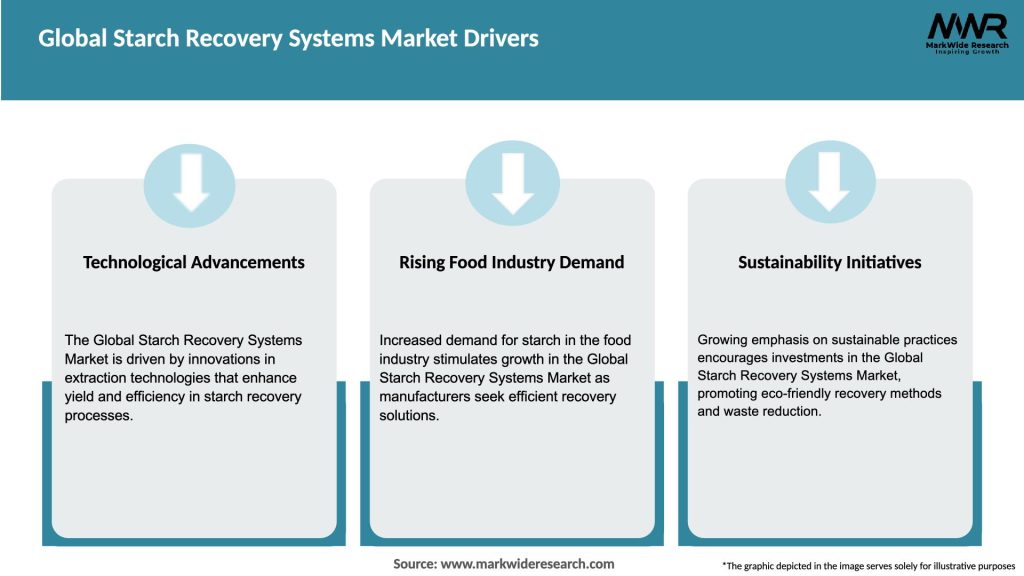

Market Drivers

Environmental Regulations: Governments worldwide are enforcing tighter wastewater discharge standards, mandating pre-treatment and recovery of solids to protect water bodies.

Sustainability Initiatives: Manufacturers are adopting circular economy practices to minimize waste and carbon footprint, with recovered starch often qualifying for green certifications.

Rising Starch Production: Increased demand for starch in food, paper, and bioethanol sectors expands the volume of process effluents, creating larger recovery opportunities.

Cost Optimization: Rising raw material prices drive processors to recapture starch that would otherwise be lost, improving profit margins.

Technological Advancements: Innovative centrifuge designs, low-energy dryers, and modular skid systems reduce operating costs and simplify maintenance.

Market Restraints

High Capital Costs: Upfront investment for turnkey starch recovery installations (US$0.5–1.5 million) can deter small-to-medium enterprises.

Operational Complexity: Skilled operators are required to fine-tune multi-stage processes, and downtime for maintenance can impact plant throughput.

Quality Variability: Recovered starch may display variable purity and viscosity, requiring blending or additional refining before reuse in certain applications.

Limited Awareness: In regions with less stringent regulations, the perceived ROI may be low, slowing adoption.

Energy Consumption: Although newer systems are more efficient, drying steps still demand significant thermal energy, impacting operating expenses.

Market Opportunities

Retrofit and Upgrade Projects: Aging starch plants can upgrade existing wastewater systems with compact recovery modules, offering a lower barrier to entry.

Emerging Economies: Fast-growing starch production in India, Brazil, and Southeast Asia presents untapped markets for turnkey recovery solutions.

Energy Integration: Coupling dryers with waste heat recovery or solar thermal systems can dramatically lower energy costs, enhancing ROI.

Value-Added Products: Processing recovered starch into glucose syrups, ethanol, or specialty biopolymers opens new revenue streams.

Digital Services: Providing remote monitoring, predictive maintenance, and performance optimization as a subscription can generate recurring revenue.

Market Dynamics

The global starch recovery systems market is characterized by dynamic factors that influence its growth and development. These dynamics include market drivers, restraints, opportunities, and trends. The market dynamics shape the competitive landscape and create opportunities for industry participants to innovate and expand their market presence.

Regional Analysis

The global starch recovery systems market is analyzed across key regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. The regional analysis provides insights into the market size, growth rate, and key trends specific to each region. It also highlights the factors driving the market in each region and the opportunities available for industry players.

Competitive Landscape

Leading Companies in the Global Starch Recovery Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

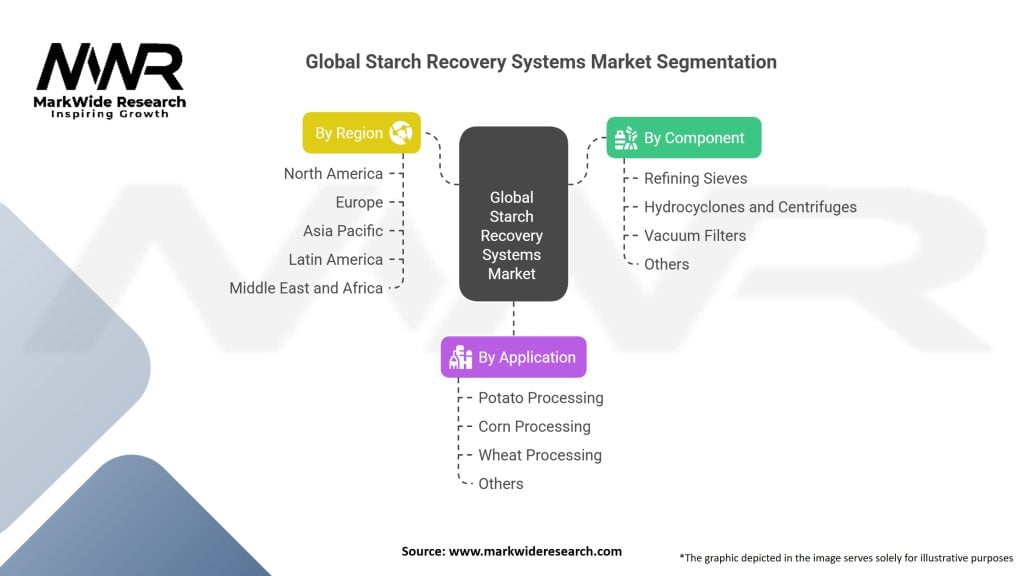

Segmentation

The global starch recovery systems market can be segmented based on system type, end-use industry, and geography. By system type, the market can be categorized into batch systems and continuous systems. Based on end-use industry, the market can be divided into food and beverage, paper and pulp, textile, and others. Geographically, the market is segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had a mixed impact on the starch recovery systems market. While the initial phase of the pandemic led to disruptions in the supply chain and a slowdown in manufacturing activities, the market has witnessed a recovery due to the growing demand for sustainable solutions. The pandemic has highlighted the importance of environmental sustainability and resource optimization, driving the adoption of starch recovery systems in various industries.

Key Industry Developments

Analyst Suggestions

Future Outlook

The global starch recovery systems market is poised for significant growth in the coming years. The increasing emphasis on sustainable practices, coupled with the rising demand for starch-based products in various industries, will drive market expansion. Technological advancements and strategic collaborations are expected to further fuel market growth, leading to the development of more efficient and advanced starch recovery systems.

Conclusion

The global starch recovery systems market is experiencing substantial growth, driven by the need for sustainable and eco-friendly solutions in the food and beverage, paper and pulp, and other industries. Starch recovery systems offer numerous benefits, including reduced waste, cost savings, and compliance with environmental regulations. Despite challenges related to initial investment costs and raw material complexities, the market presents significant opportunities for industry participants to innovate and expand their market presence. With continuous technological advancements and a growing focus on resource optimization, the future outlook for the starch recovery systems market is promising.

What are Global Starch Recovery Systems?

Global Starch Recovery Systems refer to technologies and processes used to extract and purify starch from various sources, such as corn, potatoes, and cassava. These systems are essential in food processing, biofuel production, and the manufacturing of biodegradable materials.

Who are the key players in the Global Starch Recovery Systems Market?

Key players in the Global Starch Recovery Systems Market include companies like Cargill, Archer Daniels Midland Company, and Ingredion Incorporated, which are known for their innovations in starch processing and recovery technologies, among others.

What are the main drivers of growth in the Global Starch Recovery Systems Market?

The growth of the Global Starch Recovery Systems Market is driven by increasing demand for starch in food and beverage applications, the rise in biofuel production, and the growing trend towards sustainable packaging solutions.

What challenges does the Global Starch Recovery Systems Market face?

The Global Starch Recovery Systems Market faces challenges such as fluctuating raw material prices, stringent regulations on food safety, and competition from alternative sources of starch and carbohydrates.

What opportunities exist in the Global Starch Recovery Systems Market?

Opportunities in the Global Starch Recovery Systems Market include advancements in extraction technologies, the development of new applications in the pharmaceutical and textile industries, and increasing investments in sustainable practices.

What trends are shaping the Global Starch Recovery Systems Market?

Trends shaping the Global Starch Recovery Systems Market include the growing focus on clean label products, innovations in enzymatic processing, and the integration of automation and digital technologies in starch recovery processes.

Global Starch Recovery Systems Market

| Segmentation | Details |

|---|---|

| By Component | Refining Sieves, Hydrocyclones and Centrifuges, Vacuum Filters, Others |

| By Application | Potato Processing, Corn Processing, Wheat Processing, Others |

| By Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Starch Recovery Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at