444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The global robotic grippers market is expected to grow at a steady rate over the forecast period from 2021 to 2026. Robotic grippers are an essential component of robots used in various industries such as automotive, electronics, and aerospace, among others. They help in picking up, holding, and releasing different objects in a precise manner. With the growth of automation and the adoption of Industry 4.0, the demand for robotic grippers has increased significantly. The market for robotic grippers is expected to be driven by various factors, such as the increasing demand for robots in various industries, the need for precision and accuracy in manufacturing processes, and the growing trend of collaborative robots or cobots.

Robotic grippers are a type of end effector that is attached to the end of a robotic arm. They are used to pick up and manipulate objects with different shapes, sizes, and weights. Grippers can be classified into two main types, namely parallel and angular grippers. Parallel grippers have two jaws that move in parallel to each other and are suitable for holding objects with flat surfaces. Angular grippers have jaws that move at an angle to each other and are suitable for holding objects with irregular shapes. Grippers can also be classified based on the type of actuation, such as pneumatic, hydraulic, and electric.

Executive Summary

The global robotic grippers market is expected to grow at a CAGR of XX% from 2021 to 2026, driven by the increasing demand for robots in various industries, the need for precision and accuracy in manufacturing processes, and the growing trend of collaborative robots or cobots. The market can be segmented by type, actuation, application, and region. The parallel grippers segment is expected to dominate the market during the forecast period, owing to their versatility and ability to hold objects with flat surfaces. The electric grippers segment is expected to grow at a faster rate, owing to their higher efficiency and lower maintenance costs compared to pneumatic and hydraulic grippers. The automotive and electronics industries are expected to be the largest application segments for robotic grippers, owing to their high demand for automation and precision in manufacturing processes. Asia-Pacific is expected to be the largest regional market, owing to the increasing adoption of robots in manufacturing processes and the presence of major robot manufacturers in the region.

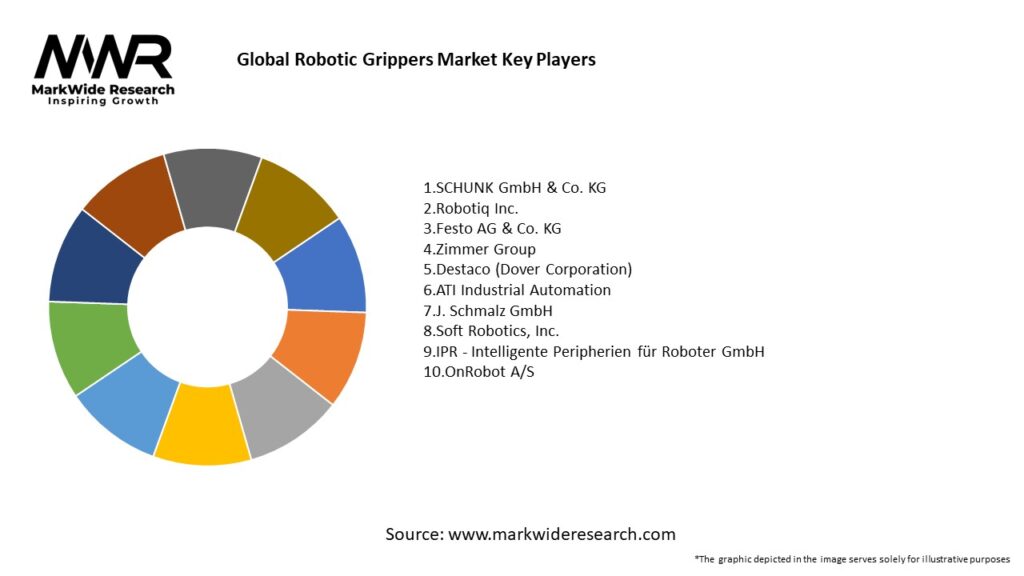

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Analysis:

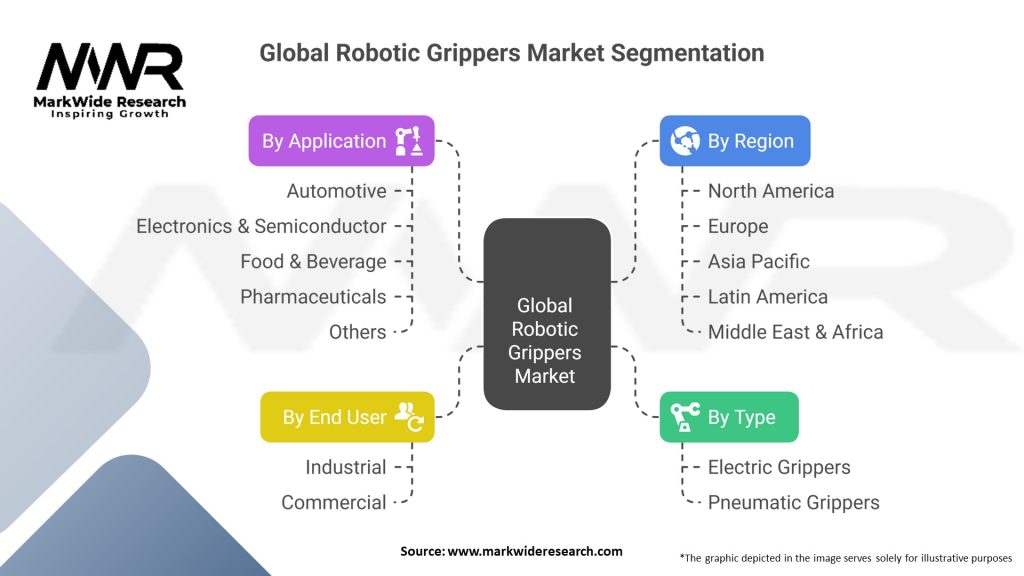

The global robotic grippers market can be segmented by type, actuation, application, and region.

By type, the market can be segmented into parallel grippers and angular grippers. The parallel grippers segment is expected to dominate the market during the forecast period, owing to their versatility and ability to hold objects with flat surfaces. The angular grippers segment is expected to grow at a faster rate, owing to their ability to hold objects with irregular shapes.

By actuation, the market can be segmented into pneumatic,

By actuation, the market can be segmented into pneumatic, hydraulic, and electric grippers. The electric grippers segment is expected to grow at a faster rate, owing to their higher efficiency and lower maintenance costs compared to pneumatic and hydraulic grippers.

By application, the market can be segmented into automotive, electronics, aerospace, food and beverage, healthcare, and others. The automotive and electronics industries are expected to be the largest application segments for robotic grippers, owing to their high demand for automation and precision in manufacturing processes.

By region, the market can be segmented into North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific is expected to be the largest regional market, owing to the increasing adoption of robots in manufacturing processes and the presence of major robot manufacturers in the region.

Market Drivers:

The global robotic grippers market is expected to be driven by various factors, such as the increasing demand for robots in various industries, the need for precision and accuracy in manufacturing processes, and the growing trend of collaborative robots or cobots.

The adoption of Industry 4.0 and the increasing focus on automation in manufacturing processes are expected to be the major drivers of the robotic grippers market. The need for precision and accuracy in manufacturing processes is also expected to drive the demand for robotic grippers, as they offer better control and flexibility compared to manual handling.

Furthermore, the growing trend of collaborative robots or cobots is expected to drive the demand for robotic grippers. Cobots are designed to work alongside humans and require grippers that can be easily integrated and programmed.

Market Restraints:

The high initial cost of robotic grippers is expected to be a major restraint for the market, as it can limit the adoption of robots in small and medium-sized enterprises. The lack of skilled labor and the complexity of programming and integrating robots are also expected to be major challenges for the market.

The safety concerns associated with the use of robots in manufacturing processes are also expected to be a major restraint, as they can lead to accidents and injuries if not properly handled.

Market Opportunities:

The growing trend of Industry 4.0 and the increasing demand for automation in various industries are expected to create significant opportunities for the robotic grippers market. The adoption of collaborative robots or cobots is also expected to create new opportunities for the market.

Furthermore, the development of advanced grippers that can handle a wide range of objects and materials is expected to create new opportunities for the market.

Market Dynamics:

The global robotic grippers market is highly dynamic, owing to the rapid advancements in technology and the increasing demand for automation in various industries.

The market is characterized by intense competition, with several players competing on the basis of product innovation, pricing, and distribution. The market is also highly fragmented, with several small and medium-sized players competing alongside large multinational corporations.

Regional Analysis:

Asia-Pacific is expected to be the largest regional market for robotic grippers, owing to the increasing adoption of robots in manufacturing processes and the presence of major robot manufacturers in the region. The region is also expected to grow at the fastest rate during the forecast period, owing to the increasing demand for automation in various industries.

North America and Europe are also expected to be major regional markets for robotic grippers, owing to the presence of several large automotive and electronics manufacturers in these regions.

Competitive Landscape:

Leading Companies in the Global Robotic Grippers Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation:

The global robotic grippers market can be segmented based on type, actuation, application, and region.

By type, the market can be segmented into:

By actuation, the market can be segmented into:

By application, the market can be segmented into:

By region, the market can be segmented into:

Category-wise Insights:

Based on the type of grippers, the parallel grippers segment is expected to dominate the market during the forecast period. Parallel grippers are versatile and can hold objects with flat surfaces, making them suitable for a wide range of applications.

Based on the type of actuation, the electric grippers segment is expected to grow at a faster rate during the forecast period. Electric grippers are more efficient and have lower maintenance costs compared to pneumatic and hydraulic grippers.

Based on the application, the automotive and electronics industries are expected to be the largest segments during the forecast period. The automotive industry requires high precision and accuracy in manufacturing processes, and robotic grippers offer better control and flexibility compared to manual handling. The electronics industry also requires precision and accuracy, and robotic grippers can handle delicate components with ease.

Key Benefits for Industry Participants and Stakeholders:

The adoption of robotic grippers can offer several benefits to industry participants and stakeholders, such as:

SWOT Analysis:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic has had a mixed impact on the global robotic grippers market. While the pandemic has led to disruptions in manufacturing processes and supply chains, it has also led to increased demand for automation and robotics in various industries.

The pandemic has highlighted the need for automation and the use of robots in manufacturing processes, as they can help reduce the risk of transmission and ensure social distancing. The demand for robotic grippers is expected to increase in the post-pandemic period, as companies focus on automation and increasing efficiency in manufacturing processes.

Key Industry Developments:

Analyst Suggestions:

Industry analysts suggest that the global robotic grippers market is expected to grow at a steady rate over the forecast period, driven by the increasing demand for robots in various industries and the need for precision and accuracy in manufacturing processes. The adoption of collaborative robots or cobots is also expected to create new opportunities for the market. Companies should focus on product innovation, pricing, and distribution to remain competitive in the market.

Future Outlook:

The global robotic grippers market is expected to continue growing at a steady rate over the forecast period from 2021 to 2026. The adoption of Industry 4.0 and the increasing focus on automation in manufacturing processes are expected to drive the demand for robotic grippers. The growing trend of collaborative robots or cobots is also expected to create new opportunities for the market. The development of advanced grippers that can handle a wide range of objects and materials is a key trend in the market. Companies should focus on product innovation, pricing, and distribution to remain competitive in the market.

Conclusion:

The global robotic grippers market is expected to grow at a steady rate over the forecast period from 2021 to 2026, driven by the increasing demand for robots in various industries and the need for precision and accuracy in manufacturing processes. The adoption of Industry 4.0 and the growing trend of collaborative robots or cobots are expected to create new opportunities for the market. Companies should focus on product innovation, pricing, and distribution to remain competitive in the market.

What are robotic grippers in the context of the Global Robotic Grippers Market?

Robotic grippers are mechanical devices used in automation to grasp, manipulate, and handle objects. They are essential components in various applications, including manufacturing, logistics, and assembly lines.

Which companies are leading the Global Robotic Grippers Market?

Leading companies in the Global Robotic Grippers Market include ABB, KUKA, and FANUC, which are known for their innovative solutions and extensive product offerings in automation technology, among others.

What are the key drivers of growth in the Global Robotic Grippers Market?

Key drivers of growth in the Global Robotic Grippers Market include the increasing demand for automation in manufacturing, the rise of e-commerce requiring efficient logistics solutions, and advancements in robotics technology enhancing gripper capabilities.

What challenges does the Global Robotic Grippers Market face?

Challenges in the Global Robotic Grippers Market include high initial investment costs, the need for skilled labor to operate and maintain robotic systems, and the integration of grippers with existing manufacturing processes.

What future opportunities exist in the Global Robotic Grippers Market?

Future opportunities in the Global Robotic Grippers Market include the development of smart grippers with AI capabilities, expansion into new industries such as healthcare and agriculture, and the growing trend of collaborative robots working alongside humans.

What trends are shaping the Global Robotic Grippers Market?

Trends shaping the Global Robotic Grippers Market include the increasing adoption of soft robotics for delicate handling, the integration of machine learning for improved performance, and the focus on sustainability in manufacturing processes.

Global Robotic Grippers Market:

| Segmentation Details | Details |

|---|---|

| By Type | Electric Grippers, Pneumatic Grippers |

| By Application | Automotive, Electronics & Semiconductor, Food & Beverage, Pharmaceuticals, Others |

| By End User | Industrial, Commercial |

| By Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Robotic Grippers Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at