Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

-

Process Efficiency & Cost Savings: Accurate reflux control can reduce steam consumption in reboilers by up to 15%, translating to significant cost savings for large-scale operations.

-

Digital Integration: Smart reflux controllers equipped with predictive analytics are reducing unplanned downtime by up to 20%.

-

Regulatory Compliance: Adoption of low-emission processes and wastewater minimization in industries such as petrochemicals and specialty chemicals heightens demand for precise reflux testing.

-

Retrofit Demand: Aging distillation columns in mature markets (North America, Europe) are being retrofitted with modern reflux systems to extend lifespan and improve output quality.

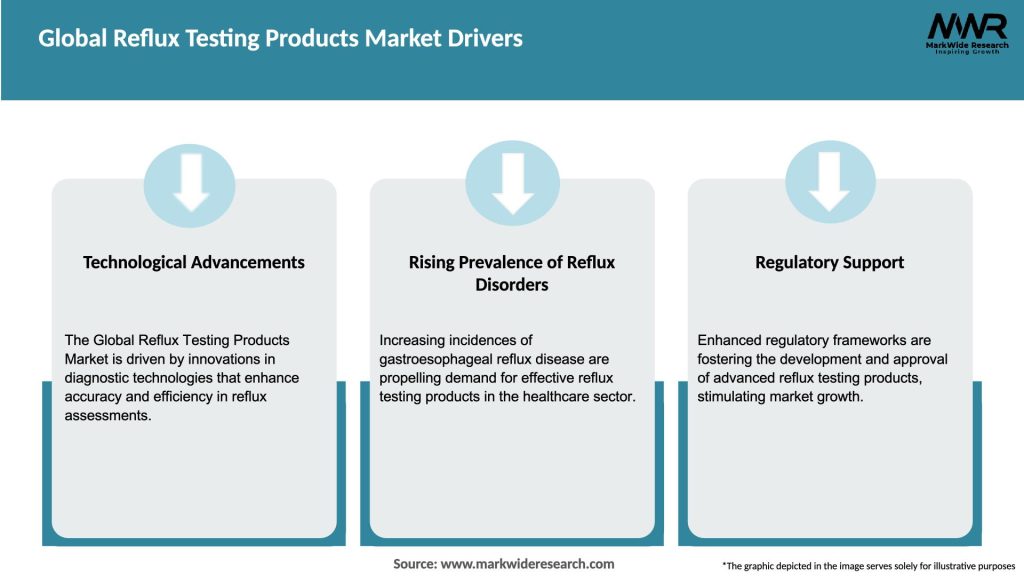

Market Drivers

-

Rising Industrial Output: Booming petrochemical, refinery, and pharmaceutical sectors necessitate high-purity separations, driving investment in reflux testing.

-

Energy Efficiency Mandates: Government policies on carbon emissions and energy conservation incentivize operators to optimize reflux ratios.

-

Technological Advancements: Development of compact, modular reflux units and integration with digital twin technology for virtual commissioning and performance optimization.

-

Quality & Safety Regulations: Stricter product specifications (e.g., pharma Active Pharmaceutical Ingredients purity) require reliable reflux measurement and control.

-

Service-Based Models: Growth of “Reflux-as-a-Service” offerings lowers the barrier to entry for small and medium-scale operators.

Market Restraints

-

High Capital Costs: Acquisition and installation of advanced reflux testing equipment can exceed USD 200,000 per column, limiting adoption in small-scale facilities.

-

Technical Complexity: Operation and maintenance require skilled process engineers, creating a talent bottleneck in emerging regions.

-

Integration Challenges: Retrofitting modern controllers into legacy DCS/SCADA systems can be time-consuming and costly.

-

Economic Volatility: Fluctuations in oil prices and downstream margins can delay capital expenditure projects.

-

Supply Chain Disruptions: Dependence on specialized sensors and custom-built condensers makes the market vulnerable to component shortages and geopolitical risks.

Market Opportunities

-

Emerging Economies Expansion: Rapid industrialization in Asia‑Pacific and Middle East countries will spur new distillation installations.

-

Greenfield Projects: Investments in new bio‑refineries, chemical parks, and pharmaceutical clusters create demand for cutting-edge reflux solutions.

-

Aftermarket & Services: Calibration, maintenance, and training services are high‑margin extensions for original equipment manufacturers (OEMs).

-

Hybrid Reflux Systems: Combining traditional condensers with heat‑pump‑based recovery systems offers superior energy savings and lower total cost of ownership (TCO).

-

Collaborative R&D: Partnerships with process licensors (e.g., UOP, Lummus) to co‑develop reflux solutions tailored for novel separation processes (e.g., ionic liquid extraction).

Market Dynamics

-

Supply Dynamics: Leading OEMs (e.g., Alfa Laval, Sulzer, Mott Corporation) are investing in automated manufacturing and digital QA to ensure consistent quality and faster lead times.

-

Demand Dynamics: Demand peaks correlate with refinery turnarounds and pharma regulatory compliance cycles, creating cyclical order flows.

-

Economic Factors: Global GDP growth rates and industrial CAPEX budgets directly influence reflux equipment procurement.

Regional Analysis

-

North America: Mature refineries and chemical plants drive retrofit projects; high tech adoption rate in shale gas separation.

-

Europe: Stringent EU emissions and energy directives accelerate adoption of energy‑efficient reflux testing. Germany and Italy lead in modular reflux systems for specialty chemicals.

-

Asia-Pacific: Fastest‑growing region; China and India’s expanding refinery and pharma sectors account for >40% of global unit demand.

-

Middle East & Africa: Mega‑refinery projects (e.g., Saudi Vision 2030) and petrochemical expansions drive greenfield installation of reflux systems.

-

Latin America: Growing ethanol and biodiesel plants in Brazil and Argentina adopt reflux testing to ensure fuel quality.

Competitive Landscape

Leading companies in the Global Reflux Testing Products Market:

- Medtronic plc

- Johnson & Johnson Services, Inc.

- OLYMPUS CORPORATION

- Sandhill Scientific, Inc.

- Sierra Scientific Instruments Inc.

- Given Imaging Ltd. (Medtronic)

- Mui Scientific

- Diversatek, Inc.

- Restech Medical Solutions

- Recordati S.p.A.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

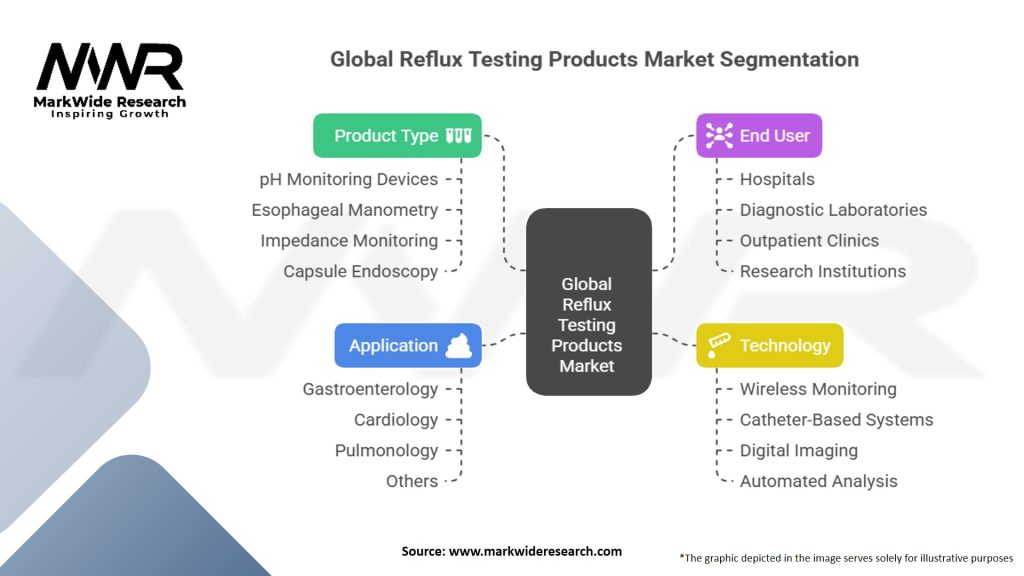

Segmentation

-

By Product Type:

-

Reflux Condensers (shell‑and‑tube, coil, plate)

-

Reflux Meters & Controllers (analog, digital PID, PLC/SCADA integrated)

-

Reflux Analyzers (GC, near‑IR, density meters)

-

Sensors & Software (temperature, flow, level, data analytics platforms)

-

-

By End‑User Industry:

-

Petrochemical & Refining

-

Chemical & Specialty Chemicals

-

Pharmaceutical & Biotechnology

-

Food & Beverage

-

Biofuels & Renewable Fuels

-

-

By Deployment Mode:

-

New Installations (greenfield projects)

-

Retrofit & Upgrades (brownfield projects)

-

-

By Region:

-

North America

-

Europe

-

Asia‑Pacific

-

Middle East & Africa

-

Latin America

-

Category-wise Insights

-

Reflux Condensers: Shell‑and‑tube designs dominate due to robustness; plate condensers are growing for compact installations.

-

Controllers & Meters: Digital PID controllers now outpace analog systems as operators demand remote monitoring and tighter control (±0.5% reflux ratio).

-

Online Analyzers: Real‑time composition monitoring (via near‑IR) is increasingly integrated, replacing manual grab‑sample GC analysis.

-

Software Platforms: Cloud‑based analytics enable predictive maintenance and performance benchmarking across multiple units.

Key Benefits for Industry Participants and Stakeholders

-

Process Optimization: Tight reflux control improves separation efficiency by 5–10%, leading to higher product yields.

-

Energy Savings: Better control reduces steam and cooling utility costs by up to 15%.

-

Operational Safety: Early detection of deviations prevents column flooding and potential process upsets.

-

Regulatory Adherence: Accurate record keeping ensures compliance with environmental and safety audits.

-

Reduced Downtime: Predictive analytics minimize unplanned maintenance, improving plant availability by 3–5%.

SWOT Analysis

Strengths:

-

Established technology with proven ROI.

-

Strong integration with broader process control systems.

-

Essential for compliance and safety.

Weaknesses:

-

High capital and installation costs.

-

Dependence on skilled personnel for operation and maintenance.

-

Retrofits can be disruptive to ongoing operations.

Opportunities:

-

Growth in emerging markets’ petrochemical and pharmaceutical sectors.

-

Increasing demand for energy‑efficient, low‑carbon operations.

-

Expansion of service offerings (rental, O&M contracts, digital twins).

Threats:

-

Economic downturns impacting CAPEX budgets.

-

Technological disruption from alternative separation technologies (e.g., membrane distillation).

-

Supply chain vulnerabilities for specialized components.

Market Key Trends

-

Digital Twin Deployment: Virtual modeling of column‑reflux dynamics for performance forecasting and optimization.

-

IoT‑Enabled Systems: Wireless sensor networks feeding centralized analytics dashboards for holistic plant monitoring.

-

Modular Skid‑Based Systems: Pre‑built reflux units reduce site installation time by 30%.

-

Green Reflux Technologies: Integration of heat‑pump‑based condensers for lower cooling water usage and carbon footprint.

-

Subscription Models: Move toward “Reflux Testing as a Service,” enabling flexible OPEX‑based procurement.

Covid-19 Impact

-

Project Delays: Temporary suspension of non‑critical CAPEX affected retrofit timelines.

-

Supply Chain Strain: Disruptions in global logistics led to extended lead times for condensers and controllers.

-

Accelerated Digital Adoption: Lockdowns prompted remote monitoring solutions and virtual start‑up assistance, boosting digital product sales.

-

Focus on Resilience: Operators prioritized investments that enhance process reliability and allow remote operations.

-

Service Flexibility: Flexible service contracts gained popularity as companies sought to manage OPEX and cash flow.

Key Industry Developments

-

Alfa Laval’s Digital Condenser Series: Launch of IoT‑connected plate condenser with built‑in sensors and cloud analytics capability.

-

Sulzer’s Smart Reflux Meter: Introduction of a compact, clamp‑on reflux meter leveraging ultrasound to eliminate line penetration.

-

Mott’s Static Mixer Integration: Hybrid mixer‑condenser modules that improve phase contact and heat transfer by 20%.

-

Emerson’s DeltaV Reflux Suite: Enhanced control algorithms embedded in DCS for automated reflux ratio optimization.

-

Endress+Hauser’s WirelessHART Sensors: Battery‑powered field sensors for temperature and flow, enabling retrofit in remote installations.

Analyst Suggestions

-

Invest in Digital Retrofit Kits: Develop open‑architecture sensor and controller modules that integrate with legacy DCS to expand addressable market.

-

Offer Reflux‑as‑a‑Service: Provide subscription‑based models including equipment, maintenance, and remote monitoring to lower customer entry barriers.

-

Focus on Modular Design: Standardize skid‑mounted reflux units for rapid deployment in greenfield and brownfield projects.

-

Enhance Predictive Analytics: Leverage AI/ML algorithms on historical reflux and process data to predict deviations before they occur.

-

Target Niche Industries: Expand beyond petrochemicals into food & beverage, biofuels, and specialty chemicals where reflux testing needs are growing.

Future Outlook

The Global Reflux Testing Products Market is poised for sustained growth driven by ongoing digital transformation, energy efficiency mandates, and expanding process industries in emerging economies. Key factors shaping the future include:

-

Advanced Digital Ecosystems: Increasing adoption of cloud‑native architectures and edge computing for faster, localized reflux control.

-

Sustainability Pressures: Demand for low‑carbon, water‑saving reflux technologies will accelerate product innovation.

-

Convergence with Process Analytics: Reflux control systems will become central nodes in integrated process‑optimization platforms, linking lab‑scale analytics to full‑scale production.

-

Lifecycle Service Models: Shift from one‑time sales to lifecycle partnerships, encompassing service, support, and continuous performance tracking.

-

Global Standardization: Development of international standards for reflux testing accuracy, communication protocols, and cybersecurity will enhance interoperability and market confidence.

Conclusion

The Global Reflux Testing Products Market stands at the intersection of operational excellence, regulatory compliance, and digital innovation. As process industries strive to achieve higher efficiencies, lower emissions, and improved product quality, reflux testing products—spanning condensers, controllers, analyzers, and software—will remain indispensable. Market participants that embrace digital integration, modular design, and service‑centric models will unlock new growth avenues and deliver transformative value to customers worldwide. Through strategic R&D, collaborative partnerships, and a relentless focus on sustainability, the reflux testing ecosystem is set to drive the next wave of process optimization and energy‑efficient manufacturing.