444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The global industrial enclosures market has witnessed significant growth in recent years, driven by the increasing demand for secure and reliable protection of industrial equipment and machinery. Industrial enclosures are specially designed structures that provide physical and environmental protection to sensitive electronic components and machinery in various industries. These enclosures are made from robust materials such as steel, aluminum, and plastic, ensuring durability and resistance to harsh environmental conditions.

Meaning

Industrial enclosures serve as protective housings for critical equipment, allowing them to operate efficiently in challenging environments. These enclosures are designed to safeguard electronic components from dust, moisture, temperature fluctuations, and physical damage. They are used across a wide range of industries, including manufacturing, oil and gas, energy, telecommunications, and transportation, to name a few. Industrial enclosures come in different sizes and configurations to accommodate various equipment and can be customized to meet specific requirements.

Executive Summary

The global industrial enclosures market has experienced substantial growth over the past few years and is expected to continue expanding at a steady rate. The increasing adoption of automation and advanced machinery in industries worldwide is a key driver for the market. Additionally, the growing focus on workplace safety and the need for secure protection of sensitive electronic equipment have further fueled the demand for industrial enclosures.

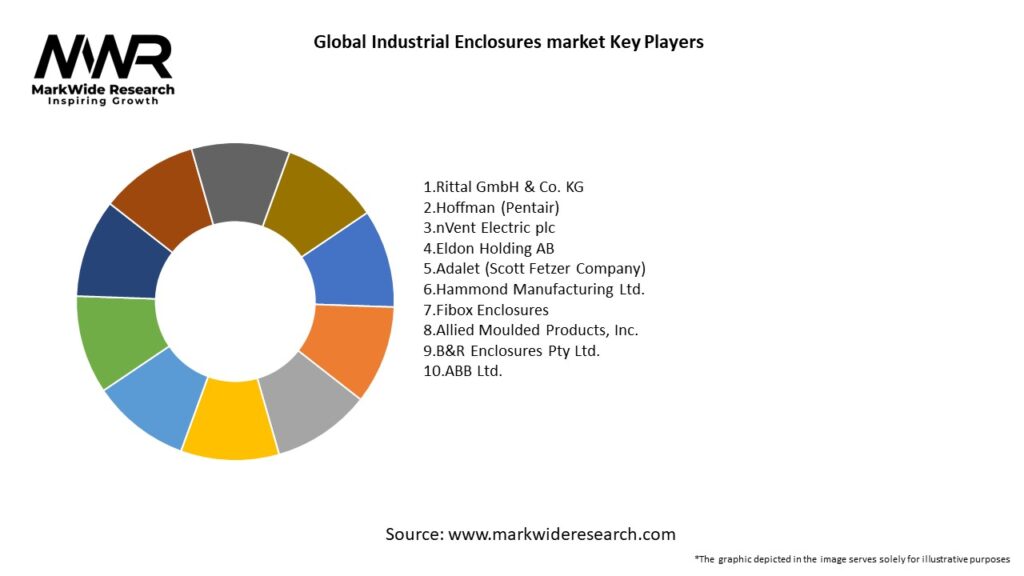

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

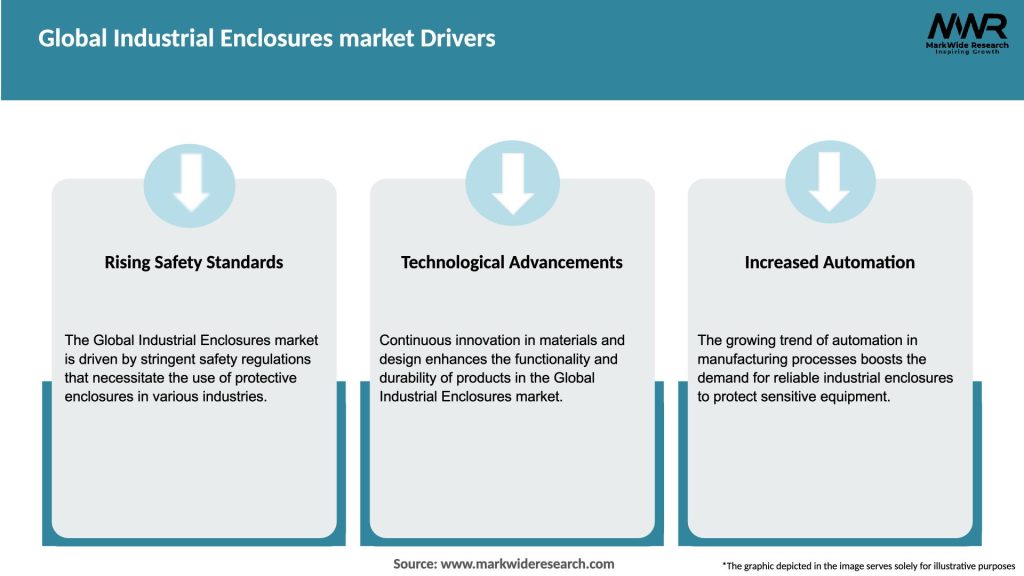

Market Drivers

The industrial enclosures market is driven by several factors. Firstly, the rising demand for secure and reliable protection of industrial equipment and machinery is a significant driver. With the increasing complexity and sensitivity of electronic components, industries are increasingly recognizing the importance of providing adequate physical and environmental protection. Industrial enclosures offer a robust solution to safeguard equipment from dust, moisture, and other damaging elements.

Moreover, the widespread adoption of automation and advanced machinery in industries is contributing to the market growth. As industries transition towards smart manufacturing and Industry 4.0 concepts, the need for enclosures to house sophisticated electronic components and control systems becomes crucial. These enclosures not only protect the equipment but also ensure their proper functioning by maintaining optimal operating conditions.

Market Restraints

Despite the positive growth prospects, the industrial enclosures market faces some challenges. One of the primary restraints is the high cost associated with the procurement and installation of industrial enclosures. These enclosures often require customization to fit specific equipment and environmental requirements, leading to additional expenses. Moreover, the maintenance and repair costs of industrial enclosures can also be substantial, affecting the overall affordability for end-users.

Additionally, the availability of alternative protection solutions, such as industrial cabinets and racks, can pose a challenge to the market. Some industries may opt for these alternatives, especially when the equipment is not as sensitive or when space constraints limit the use of enclosures. The competition from alternative products can impact the growth of the industrial enclosures market to some extent.

Market Opportunities

The industrial enclosures market offers several opportunities for growth and innovation. One such opportunity lies in the development of lightweight and corrosion-resistant enclosure materials. The demand for lightweight enclosures is increasing, particularly in industries where mobility and portability are essential, such as transportation and telecommunications.

Another opportunity arises from the adoption of modular enclosure designs. Modular enclosures allow for flexibility and scalability, enabling industries to modify and expand their equipment as needed. The ability to add or remove enclosure modules based on changing requirements presents a significant advantage, especially in industries with dynamic operational needs.

Market Dynamics

The industrial enclosures market is driven by a combination of factors, including technological advancements, industry trends, and regulatory requirements. Technological advancements in enclosure materials and designs have played a crucial role in expanding the market. Manufacturers are continually investing in research and development to introduce innovative materials that offer enhanced durability, corrosion resistance, and cost-effectiveness.

Industry trends, such as the increasing adoption of automation and smart manufacturing, are driving the demand for industrial enclosures. The integration of advanced machinery and control systems requires reliable and secure enclosures to protect the sensitive components.

Additionally, regulatory requirements related to workplace safety and equipment protection influence the market dynamics. Industries must comply with safety standards and regulations, which often include guidelines for the use of protective enclosures. These regulations create a steady demand for industrial enclosures across various sectors.

Regional Analysis

The global industrial enclosures market can be segmented into several regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

North America: The North American market holds a significant share in the global industrial enclosures market. The region is home to several major industries, such as manufacturing, energy, and oil and gas, which contribute to the demand for industrial enclosures. Moreover, the stringent regulatory standards regarding workplace safety and equipment protection further drive the market growth.

Europe: Europe is another prominent region in the industrial enclosures market. The presence of established industries and the focus on automation and smart manufacturing fuel the demand for enclosures. Additionally, the emphasis on renewable energy and the expansion of the energy sector offer growth opportunities for the market in Europe.

Asia Pacific: The Asia Pacific region is witnessing rapid industrialization and infrastructure development, leading to increased demand for industrial enclosures. Countries such as China, India, and Japan are investing heavily in manufacturing and energy sectors, driving the market growth. The presence of a large consumer electronics market also contributes to the demand for enclosures.

Latin America, Middle East, and Africa: These regions offer significant growth potential for the industrial enclosures market. The expansion of industries, including oil and gas, mining, and telecommunications, presents opportunities for the market. The rising focus on industrial safety and the need to protect equipment from harsh environmental conditions further drive the demand for enclosures.

Competitive Landscape

Leading Companies in the Global Industrial Enclosures Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

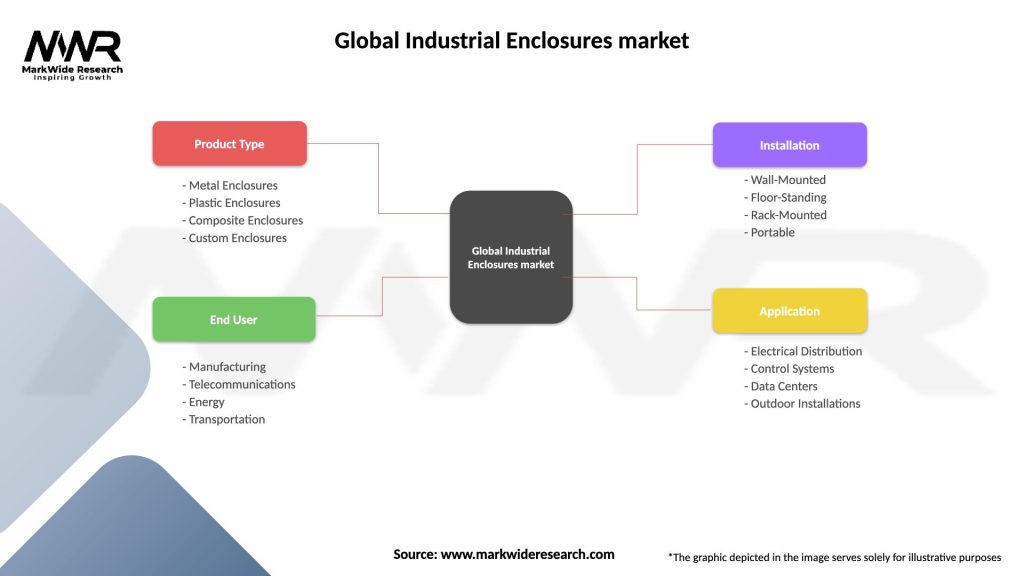

Segmentation

The industrial enclosures market can be segmented based on type, material, industry vertical, and region.

By Type:

By Material:

By Industry Vertical:

Category-wise Insights

Wall-Mounted Enclosures: Wall-mounted enclosures are widely used in various industries, especially in manufacturing and energy sectors. They offer a compact and space-saving solution for protecting equipment. Wall-mounted enclosures come in different sizes and materials to accommodate a range of equipment.

Free-Standing Enclosures: Free-standing enclosures are commonly used when the equipment requires more space or when multiple devices need to be housed together. These enclosures provide ample room for equipment installation and allow for easy access and maintenance.

Underground Enclosures: Underground enclosures are primarily used in telecommunications and utility applications. They are designed to be buried underground and provide protection for cables, wiring, and other infrastructure components.

Junction Boxes: Junction boxes are used to house electrical connections and provide a safe and organized environment for wiring. They are essential in various industries, including construction, manufacturing, and transportation.

Key Benefits for Industry Participants and Stakeholders

The industrial enclosures market offers several benefits for industry participants and stakeholders.

Enhanced Equipment Protection: Industrial enclosures provide a secure and protective environment for sensitive equipment, ensuring optimal performance and longevity.

Compliance with Safety Standards: By using industrial enclosures, industries can comply with safety standards and regulations, promoting a safe working environment.

Increased Operational Efficiency: Properly protected equipment is less prone to damage, reducing downtime and increasing operational efficiency.

Customization and Flexibility: Industrial enclosures can be customized to meet specific equipment and environmental requirements. They offer flexibility in terms of size, material, and design.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The global industrial enclosures market, like many other industries, was affected by the COVID-19 pandemic. The pandemic led to disruptions in the global supply chain and a temporary slowdown in industrial activities. Many manufacturing facilities faced production halts or reduced operations, impacting the demand for industrial enclosures.

However, the pandemic also highlighted the importance of resilient and secure infrastructure, including the protection of critical equipment. As industries resumed operations and adapted to the new normal, the need for industrial enclosures remained vital. The focus on workplace safety and equipment protection further reinforced the demand for enclosures.

The post-pandemic recovery is expected to drive the market growth as industries invest in upgrading their infrastructure and adopting advanced technologies. The growing emphasis on automation, remote monitoring, and control systems will continue to fuel the demand for industrial enclosures in the coming years.

Key Industry Developments

Analyst Suggestions

Future Outlook

The global industrial enclosures market is poised for steady growth in the coming years. The increasing adoption of automation, IoT, and Industry 4.0 concepts across industries will continue to drive the demand for enclosures. Additionally, the focus on workplace safety and equipment protection will remain a key factor in the market growth. Emerging markets, particularly in Asia Pacific and Latin America, present significant growth opportunities due to rapid industrialization and infrastructure development. The development of lightweight and corrosion-resistant enclosure materials, along with the integration of advanced technologies, will further enhance the market’s prospects.

The market is expected to witness increased competition among key players, leading to further product innovation and advancements. Customization, scalability, and sustainability will be key focus areas for manufacturers to stay competitive and meet evolving customer demands.

Conclusion

In conclusion, the global industrial enclosures market is experiencing steady growth, driven by the need for secure and reliable protection of industrial equipment. The increasing adoption of automation, advanced machinery, and regulatory requirements for workplace safety are key drivers for the market. Industry participants and stakeholders can benefit from enhanced equipment protection, compliance with safety standards, increased operational efficiency, and customization options offered by industrial enclosures. Manufacturers should focus on product innovation, sustainability, and collaboration to stay competitive and meet the evolving needs of industries. Overall, the future outlook for the global industrial enclosures market is positive, with sustained growth expected in the coming years.

What is Industrial Enclosures?

Industrial enclosures are protective housings designed to safeguard electrical and electronic equipment from environmental factors such as dust, moisture, and temperature fluctuations. They are commonly used in various industries, including manufacturing, telecommunications, and energy.

What are the key players in the Global Industrial Enclosures market?

Key players in the Global Industrial Enclosures market include Schneider Electric, Rittal, and Eaton, which are known for their innovative solutions and extensive product ranges. These companies focus on providing high-quality enclosures for diverse applications, among others.

What are the main drivers of growth in the Global Industrial Enclosures market?

The growth of the Global Industrial Enclosures market is driven by increasing demand for automation in industries, the need for equipment protection in harsh environments, and the expansion of renewable energy projects. Additionally, the rise in smart manufacturing technologies is contributing to market expansion.

What challenges does the Global Industrial Enclosures market face?

The Global Industrial Enclosures market faces challenges such as the high cost of advanced materials and the need for compliance with stringent regulations. Additionally, competition from low-cost manufacturers can impact pricing strategies and market share.

What opportunities exist in the Global Industrial Enclosures market?

Opportunities in the Global Industrial Enclosures market include the growing adoption of IoT devices and smart technologies, which require robust enclosures for protection. Furthermore, the increasing focus on sustainability and energy efficiency presents avenues for innovation in enclosure design.

What trends are shaping the Global Industrial Enclosures market?

Trends in the Global Industrial Enclosures market include the integration of smart technologies into enclosure designs, the use of sustainable materials, and the development of customizable solutions to meet specific industry needs. These trends are driving innovation and enhancing product functionality.

Global Industrial Enclosures market

| Segmentation Details | Description |

|---|---|

| Product Type | Metal Enclosures, Plastic Enclosures, Composite Enclosures, Custom Enclosures |

| End User | Manufacturing, Telecommunications, Energy, Transportation |

| Installation | Wall-Mounted, Floor-Standing, Rack-Mounted, Portable |

| Application | Electrical Distribution, Control Systems, Data Centers, Outdoor Installations |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Industrial Enclosures Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at