444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The global industrial control and factory automation market has witnessed significant growth in recent years. This market encompasses a wide range of technologies and solutions that are used to automate and control various industrial processes. Industrial control and factory automation systems are employed across different industries, including manufacturing, oil and gas, automotive, pharmaceuticals, and food and beverage, among others.

Meaning

Industrial control and factory automation refer to the implementation of advanced technologies and systems to streamline and optimize industrial processes. These systems utilize various hardware and software components to monitor, control, and automate manufacturing operations. Industrial control systems are responsible for controlling machinery, processes, and equipment, while factory automation involves the integration of various processes within a factory setting.

Executive Summary

The global industrial control and factory automation market has experienced substantial growth in recent years. The increasing need for operational efficiency, improved productivity, and cost reduction has driven the adoption of automation technologies in the industrial sector. Additionally, the growing demand for enhanced safety measures and stringent regulations has further accelerated the market growth. With the advent of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and robotics, the industrial control and factory automation market is poised for continued expansion.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

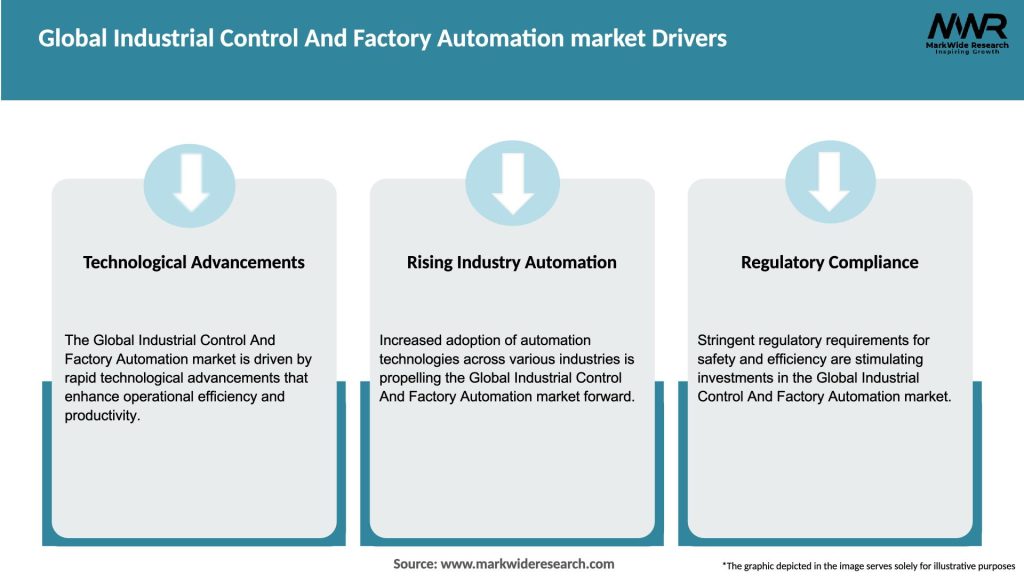

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The global industrial control and factory automation market is driven by a combination of factors, including technological advancements, regulatory requirements, and the need for operational efficiency. The market dynamics are shaped by the interplay of market drivers, restraints, and opportunities, along with the evolving customer demands and industry trends. Understanding these dynamics is crucial for businesses operating in the industrial control and factory automation space to capitalize on growth opportunities and stay competitive.

Regional Analysis

The industrial control and factory automation market is analyzed across various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its own unique characteristics and market dynamics. North America and Europe are mature markets with well-established manufacturing sectors, while Asia Pacific is witnessing rapid industrialization and urbanization, driving the demand for automation technologies. Latin America and the Middle East and Africa are emerging markets that offer significant growth potential for industrial control and factory automation.

Competitive Landscape

Leading Companies in the Global Industrial Control and Factory Automation Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

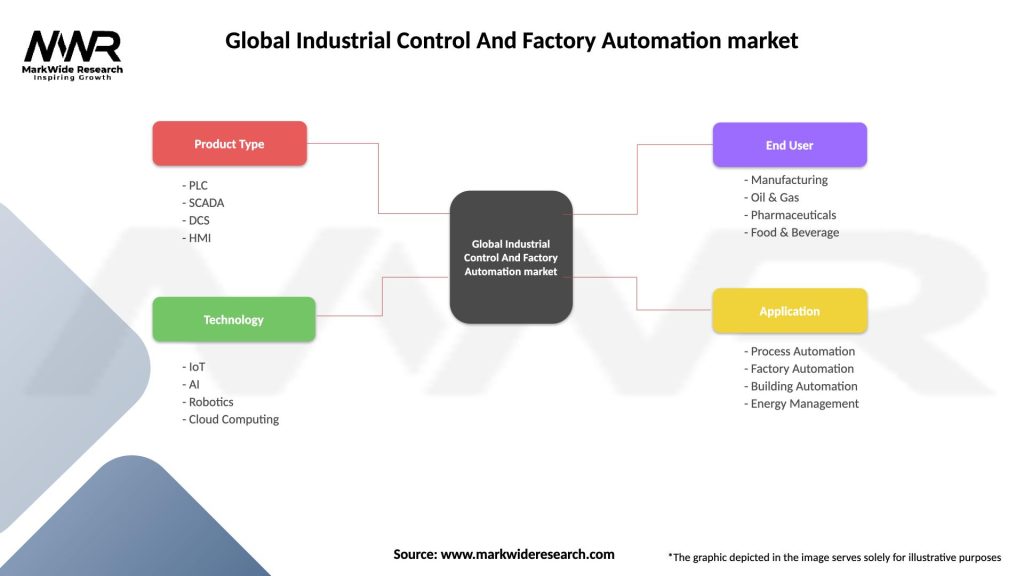

Segmentation

The industrial control and factory automation market can be segmented based on various factors, including technology, component, industry vertical, and geography. The technology segment includes programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA), human-machine interface (HMI), distributed control systems (DCS), and others. The component segment comprises hardware, software, and services. Industry verticals that adopt industrial control and factory automation systems include manufacturing, oil and gas, automotive, pharmaceuticals, food and beverage, and others.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

The SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis provides a comprehensive assessment of the industrial control and factory automation market:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the industrial control and factory automation market. The disruption in global supply chains, lockdown measures, and economic slowdown affected manufacturing activities worldwide. However, the pandemic also highlighted the importance of automation technologies in ensuring business continuity and operational resilience. The need for social distancing and reducing human contact accelerated the adoption of automation systems, particularly in industries such as pharmaceuticals, healthcare, and e-commerce. The market witnessed increased demand for remote monitoring, predictive maintenance, and robotics. As the world recovers from the pandemic, the adoption of industrial control and factory automation is expected to further accelerate.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the global industrial control and factory automation market is highly promising. The market is expected to witness continued growth, driven by technological advancements, increasing demand for operational efficiency, and the need for enhanced safety measures. The integration of IoT, AI, and robotics will further revolutionize industrial processes, enabling autonomous decision-making, predictive maintenance, and optimized resource utilization. The adoption of automation technologies in emerging economies and non-traditional industries will create new growth opportunities. However, challenges such as initial investment costs, integration complexities, and cybersecurity risks need to be addressed for widespread adoption. Overall, the industrial control and factory automation market is poised for a bright future, offering immense benefits for businesses across industries.

Conclusion

The global industrial control and factory automation market has witnessed significant growth, driven by the increasing need for operational efficiency, cost reduction, and enhanced safety measures. Technological advancements such as IoT, AI, and robotics have revolutionized industrial processes, offering improved productivity, real-time insights, and data-driven decision-making. The market presents opportunities for businesses to streamline their operations, comply with regulations, and achieve sustainable manufacturing practices. However, challenges such as initial investment costs, integration complexities, and cybersecurity risks need to be addressed. By staying updated on industry trends, collaborating with technology providers, and upskilling the workforce, businesses can capitalize on the growth prospects of the industrial control and factory automation market and stay competitive in the evolving landscape.

What is Industrial Control And Factory Automation?

Industrial Control And Factory Automation refers to the use of control systems such as computers or robots for handling different processes and machinery in an industry to replace human intervention. This includes systems for controlling machinery on factory assembly lines, boilers, switching on telephone networks, and other applications.

What are the key players in the Global Industrial Control And Factory Automation market?

Key players in the Global Industrial Control And Factory Automation market include Siemens AG, Rockwell Automation, Schneider Electric, and Honeywell International, among others. These companies are known for their innovative solutions and technologies that enhance automation and control in various industrial sectors.

What are the growth factors driving the Global Industrial Control And Factory Automation market?

The growth of the Global Industrial Control And Factory Automation market is driven by the increasing demand for operational efficiency, the rise of smart manufacturing, and the integration of IoT technologies. Additionally, the need for real-time data analytics and improved safety standards in industries contributes to market expansion.

What challenges does the Global Industrial Control And Factory Automation market face?

The Global Industrial Control And Factory Automation market faces challenges such as high initial investment costs, cybersecurity threats, and the complexity of integrating new technologies with existing systems. These factors can hinder the adoption of advanced automation solutions in some industries.

What opportunities exist in the Global Industrial Control And Factory Automation market?

Opportunities in the Global Industrial Control And Factory Automation market include the growing trend of Industry Four Point Zero, advancements in AI and machine learning, and the increasing focus on sustainability and energy efficiency. These trends are expected to create new avenues for innovation and investment.

What are the current trends in the Global Industrial Control And Factory Automation market?

Current trends in the Global Industrial Control And Factory Automation market include the adoption of cloud-based solutions, the rise of collaborative robots (cobots), and the implementation of predictive maintenance strategies. These trends are reshaping how industries approach automation and control processes.

Global Industrial Control And Factory Automation market

| Segmentation Details | Description |

|---|---|

| Product Type | PLC, SCADA, DCS, HMI |

| Technology | IoT, AI, Robotics, Cloud Computing |

| End User | Manufacturing, Oil & Gas, Pharmaceuticals, Food & Beverage |

| Application | Process Automation, Factory Automation, Building Automation, Energy Management |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Industrial Control and Factory Automation Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at