444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The global industrial burner market has experienced steady growth over the years, owing to an increase in industrialization and the need for reliable and efficient heating systems. Industrial burners are critical components in various industrial applications, such as boilers, furnaces, and incinerators. They are responsible for generating heat and maintaining the temperature required for these processes. The increasing demand for industrial burners is driven by the growth of the oil and gas, power generation, chemicals, and food processing industries.

Meaning

An industrial burner is a device used in industrial applications to generate heat by burning fuel, such as natural gas, oil, or propane. It is used in a wide range of applications, such as boilers, furnaces, and incinerators. Industrial burners are designed to be efficient and reliable, providing a consistent supply of heat to industrial processes. The performance of an industrial burner is measured by its fuel efficiency, emissions, and heat output.

Executive Summary

The global industrial burner market is expected to reach a value of USD 7.3 billion by 2028, growing at a CAGR of 4.5% during the forecast period (2021-2028). The increasing demand for industrial burners from various industries, such as oil and gas, power generation, chemicals, and food processing, is driving the growth of the market. The oil and gas industry is the largest end-user segment, accounting for the majority of the market share. The Asia-Pacific region is expected to dominate the market, owing to the growth of the manufacturing sector in countries such as China, India, and Japan.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several factors are driving the growth of the Global Industrial Burner market:

Energy Efficiency Requirements: The need for reducing operational costs and improving energy efficiency in industrial processes is one of the primary drivers for the adoption of advanced industrial burners. These burners help minimize fuel consumption while maintaining optimal temperature control.

Environmental Regulations: Stringent environmental standards, such as those related to emissions of CO2, NOx, and particulate matter, are pushing industries to adopt cleaner and more efficient burners that comply with global environmental regulations.

Industrial Automation: The rise of automation in industrial heating systems is driving the demand for advanced burners with integrated control systems that can optimize combustion processes and improve overall operational efficiency.

Growing Industrialization in Emerging Markets: As industrialization continues to expand in emerging markets, particularly in Asia-Pacific, the demand for industrial burners is increasing to meet the growing need for energy-efficient heating solutions in manufacturing processes.

Shift to Renewable and Alternative Fuels: The transition to renewable energy sources, including biofuels and hydrogen, is driving innovation in burner technologies that can efficiently burn these alternative fuels while minimizing emissions.

Market Restraints

Despite its growth prospects, the Global Industrial Burner market faces several challenges:

High Initial Investment: The cost of purchasing and installing advanced industrial burners, especially those with integrated control systems and emission reduction technologies, can be prohibitively high for small and medium-sized enterprises (SMEs).

Maintenance and Operational Costs: While modern industrial burners offer improved efficiency, they can require regular maintenance and operational expertise, which may increase long-term costs for some industries.

Fuel Availability and Cost: The volatility in fuel prices, particularly for natural gas and oil, can impact the operating costs of industrial burners, making it difficult for businesses to forecast energy expenditures accurately.

Complexity of Compliance: Adhering to the ever-evolving environmental regulations and standards related to emissions can be challenging for industries, requiring constant upgrades and adjustments to burner systems to maintain compliance.

Market Opportunities

The Global Industrial Burner market presents several opportunities for growth and innovation:

Low-Emission Burners: With increasing regulatory pressures on emissions, there is a growing market opportunity for burners that are designed to reduce harmful emissions, such as NOx, CO2, and particulate matter. This includes the development of burners that can burn alternative fuels efficiently.

Hybrid and Multi-Fuel Burners: The demand for hybrid and multi-fuel burners, which can operate with different fuel types such as natural gas, oil, and biofuels, is increasing, offering flexibility and cost savings to industries looking for diversified energy sources.

Integration of IoT and AI: The integration of Internet of Things (IoT) technology and Artificial Intelligence (AI) into industrial burners can optimize performance, provide real-time data, and enable predictive maintenance, further enhancing operational efficiency and reducing downtime.

Energy Recovery Systems: The growing focus on energy conservation presents an opportunity for industrial burner manufacturers to develop systems that incorporate energy recovery technologies, reducing overall energy consumption and improving sustainability.

Market Dynamics

The Global Industrial Burner market is influenced by several dynamic factors:

Technological Innovation: Ongoing innovations in burner technologies, such as advanced combustion systems, digital controls, and emission control systems, are enhancing burner efficiency and enabling industries to meet environmental standards.

Environmental Awareness: The increasing focus on sustainability and reducing carbon footprints is driving demand for low-emission industrial burners that can provide high-efficiency combustion with minimal environmental impact.

Market Consolidation: The industrial burner market is witnessing consolidation, with large players acquiring smaller firms to expand their product portfolios and strengthen their market position, providing more comprehensive solutions to end-users.

Shifting Fuel Preferences: As industries transition to renewable energy sources and alternative fuels, industrial burner manufacturers are focusing on developing technologies that can handle these fuels while maintaining efficiency and reducing emissions.

Regional Analysis

The Global Industrial Burner market exhibits regional variations in adoption and demand:

North America: North America is a mature market for industrial burners, driven by the strong presence of manufacturing industries, regulatory requirements, and technological advancements in burner designs. The U.S. and Canada are key players in this region.

Europe: Europe is another dominant market, with stringent environmental regulations driving the demand for low-emission and high-efficiency industrial burners. Countries like Germany, the UK, and France are major contributors to market growth in this region.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth in the industrial burner market, driven by rapid industrialization, increasing manufacturing activities, and growing demand for energy-efficient solutions in countries like China, India, and Japan.

Latin America: Latin America is witnessing steady growth in the industrial burner market, particularly in countries like Brazil and Mexico, where the manufacturing sector is expanding, and industries are adopting more sustainable technologies.

Middle East & Africa: The Middle East and Africa are emerging markets for industrial burners, particularly due to the growing demand for energy-efficient solutions in industries such as oil & gas, chemicals, and manufacturing.

Competitive Landscape

Leading companies in the Global Industrial Burner market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

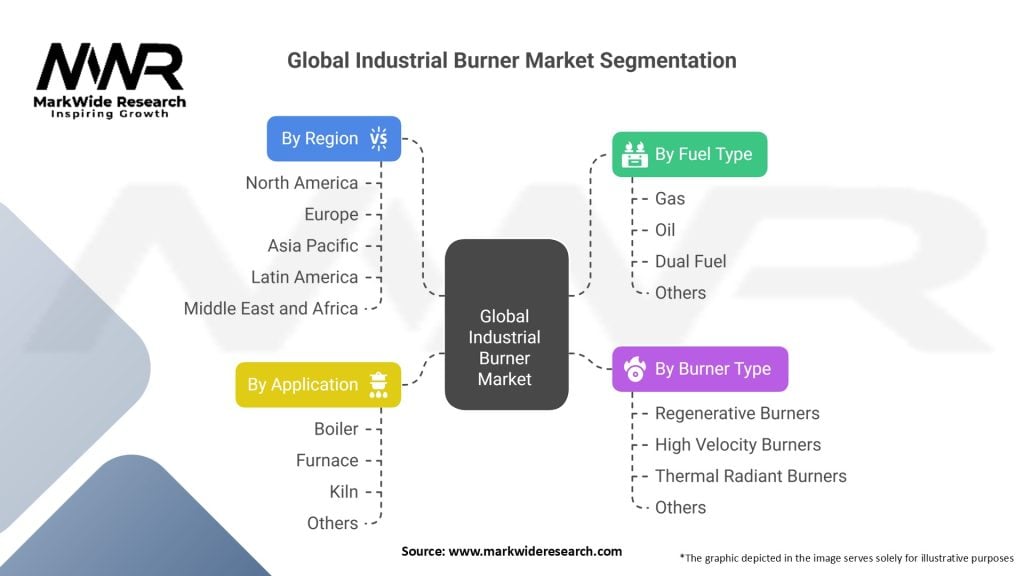

Segmentation

The Global Industrial Burner market can be segmented based on various factors:

Fuel Type: Natural Gas, Oil, Coal, Biofuels, Hydrogen, Others.

End-User Industry: Oil & Gas, Chemicals, Power Generation, Food Processing, Manufacturing, Pulp & Paper, Metals & Mining.

Burner Type: Single-Stage Burners, Multi-Stage Burners, Low-NOx Burners, High-Efficiency Burners.

Category-wise Insights

Each category of industrial burners offers unique benefits:

Key Benefits for Industry Participants and Stakeholders

The Global Industrial Burner market offers significant benefits:

Energy Savings: Industrial burners are designed to optimize fuel usage, leading to significant energy savings and reduced operational costs.

Compliance with Environmental Regulations: Advanced burner systems help industries comply with stringent emissions regulations by reducing harmful pollutants like NOx and CO2.

Improved Efficiency: Modern industrial burners ensure more efficient combustion, leading to higher thermal efficiency and more stable industrial operations.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Key trends in the Global Industrial Burner market include:

Environmental Regulations: Stricter emission control regulations are driving the demand for low-emission burners.

Fuel Diversification: Increasing use of biofuels and alternative fuels is creating opportunities for multi-fuel and hybrid burner solutions.

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the global industrial burner market, with a slowdown in the manufacturing and industrial sectors. The restrictions on movement and the closure of industries resulted in a decline in demand for industrial burners. However, the market is expected to recover in the coming years, owing to the increasing demand for energy-efficient heating systems and the growth of the end-user industries.

Key Industry Developments

The key industry developments in the global industrial burner market include the adoption of advanced technologies, such as IoT and AI, to enhance the efficiency and performance of industrial burners. The development of low-emission burners is also a significant trend in the market, with an increasing emphasis on reducing emissions and promoting sustainability. The growing demand for energy-efficient heating systems and the adoption of renewable energy sources are also key industry developments in the market.

Analyst Suggestions

The key analyst suggestions for the global industrial burner market include the adoption of advanced technologies, such as IoT and AI, to enhance the efficiency and performance of industrial burners. The key market players are also suggested to focus on product innovation and development to stay competitive in the market. The adoption of low-emission burners and renewable energy sources is also suggested to meet the growing demand for energy-efficient heating systems and promote sustainability.

Future Outlook

The global industrial burner market is expected to witness significant growth in the coming years, owing to the increasing demand for energy-efficient heating systems and the growth of the end-user industries. The adoption of advanced technologies, such as IoT and AI, is also expected to enhance the efficiency and performance of industrial burners. The key market players are expected to focus on product innovation and development to stay competitive in the market.

Conclusion

The global industrial burner market is driven by various factors, such as increasing industrialization, the growth of end-user industries, and the need for energy-efficient heating systems. The market is highly competitive, with several key players operating in the market. The adoption of advanced technologies, such as IoT and AI, is expected to enhance the efficiency and performance of industrial burners. The key analyst suggestions include the adoption of low-emission burners and renewable energy sources to promote sustainability. The market is expected to witness significant growth in the coming years, owing to the increasing demand for energy-efficient heating systems and the growth of the end-user industries.

Global Industrial Burner Market:

| Segmentation Details | Description |

|---|---|

| By Fuel Type | Gas, Oil, Dual Fuel, Others |

| By Burner Type | Regenerative Burners, High Velocity Burners, Thermal Radiant Burners, Others |

| By Application | Boiler, Furnace, Kiln, Others |

| By Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Global Industrial Burner market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at