444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The global in-circuit tester market has witnessed significant growth in recent years, driven by the increasing demand for electronic components and the rapid advancements in technology. In-circuit testers are widely used in the electronics industry to detect faults and defects in printed circuit boards (PCBs), ensuring the overall quality and reliability of electronic devices. This comprehensive market analysis delves into the key factors influencing the market, provides insights into the competitive landscape, and highlights the emerging trends and future prospects.

Meaning

An in-circuit tester, commonly known as ICT, is a specialized testing equipment used to perform functional and electrical tests on PCBs. It checks the connectivity and functionality of electronic components and detects defects such as open circuits, short circuits, and incorrect component values. By conducting tests during the manufacturing process, in-circuit testers help identify faults and ensure the proper functioning of PCBs before they are integrated into final electronic products.

Executive Summary

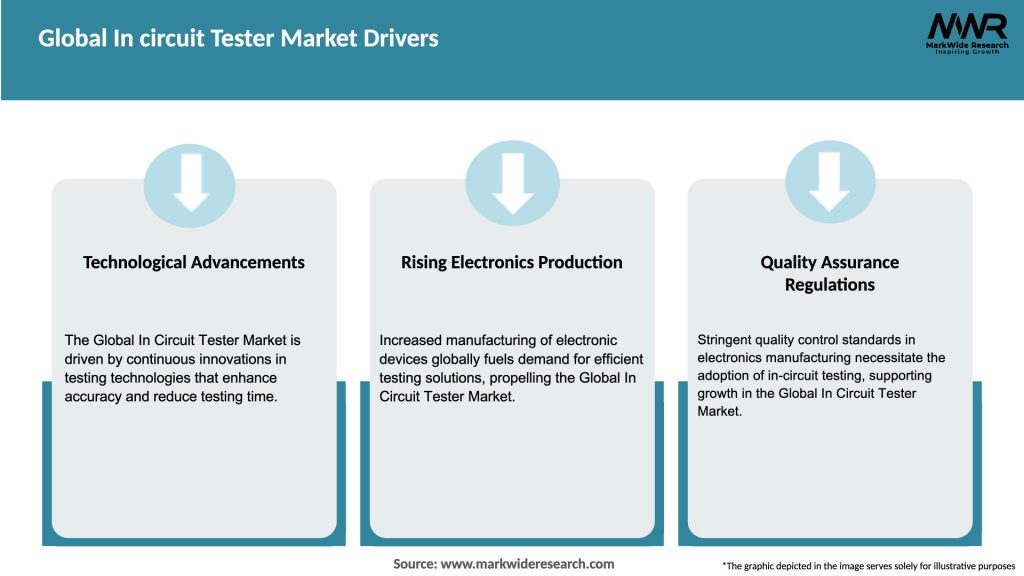

The global in-circuit tester market is projected to experience robust growth in the coming years, primarily driven by the increasing adoption of electronic devices across various industries. The rising demand for high-quality electronic components, coupled with the need for efficient testing and fault detection methods, has fueled the market growth. Furthermore, technological advancements in the field of in-circuit testing, such as the integration of artificial intelligence (AI) and machine learning (ML), have revolutionized the testing process, enhancing accuracy and efficiency.

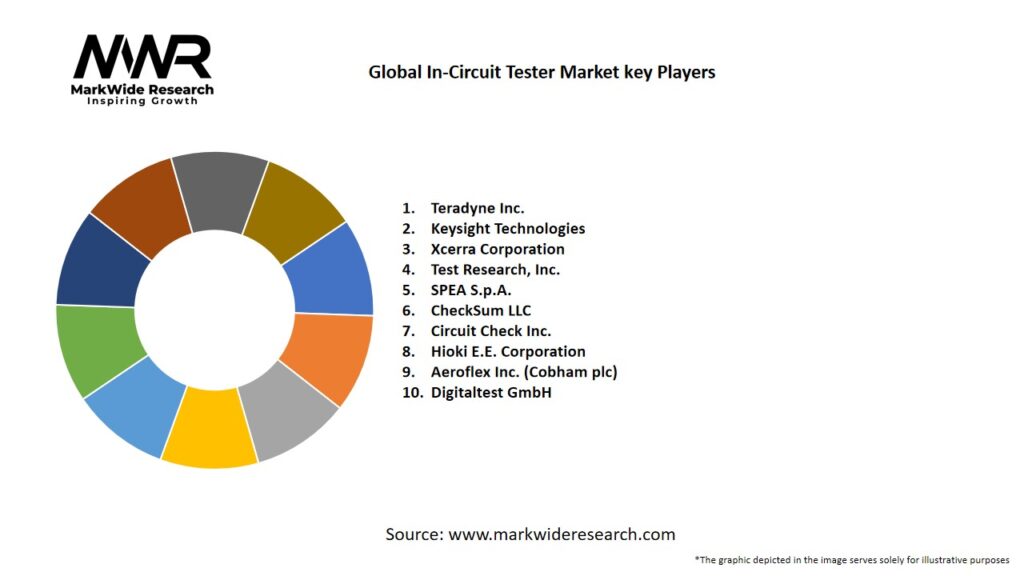

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The following factors are driving the growth of the global in-circuit tester market:

Market Restraints

Despite the positive market outlook, a few challenges are hindering the growth of the global in-circuit tester market:

Market Opportunities

Despite the challenges, the global in-circuit tester market presents several opportunities for growth:

Market Dynamics

The global in-circuit tester market is characterized by dynamic factors that influence its growth and trajectory. Key dynamics include:

Regional Analysis

The global in-circuit tester market can be segmented into several key regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

North America: The North American market holds a significant share in the global in-circuit tester market. The region is characterized by the presence of major electronic component manufacturers and advanced technology adoption across industries. The demand for in-circuit testers in sectors such as automotive, aerospace, and consumer electronics is driving market growth.

Europe: Europe is another prominent market for in-circuit testers, driven by the strong presence of automotive manufacturers and the growing demand for electronic components in various industries. The region’s focus on quality standards and compliance further boosts the market.

Asia Pacific: Asia Pacific is expected to exhibit substantial growth in the in-circuit tester market, owing to the region’s dominance in electronics manufacturing and the presence of key market players. The rapid industrialization, technological advancements, and increasing consumer electronics demand contribute to market expansion.

Latin America, Middle East, and Africa: These regions are witnessing significant growth in the electronics industry, driven by infrastructure development, urbanization, and increasing consumer disposable incomes. The rising demand for electronic devices in these regions creates opportunities for the in-circuit tester market.

Competitive Landscape

Leading Companies in the Global In-Circuit Tester Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

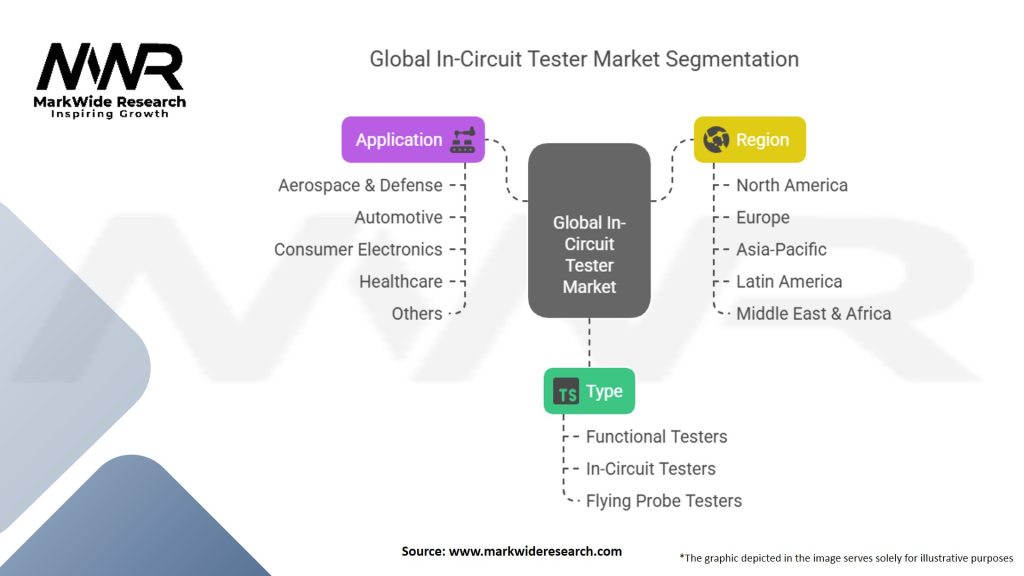

Segmentation

The global in-circuit tester market can be segmented based on various factors:

Segmentation allows for a better understanding of the market dynamics and enables targeted strategies for specific customer segments.

Category-wise Insights:

The automotive industry is a major consumer of in-circuit testers, driven by the increasing integration of electronics in vehicles. In-circuit testers play a critical role in ensuring the quality and reliability of electronic systems, such as engine control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS). The demand for in-circuit testers in the automotive industry is expected to witness steady growth due to the rising production of electric vehicles and the need for rigorous testing to ensure safety and performance.

The aerospace and defense sector relies heavily on electronic systems for navigation, communication, and monitoring purposes. In-circuit testers are crucial in this industry to ensure the integrity and reliability of electronic components used in aircraft systems. The demand for in-circuit testers in aerospace and defense is driven by strict quality standards, adherence to regulatory requirements, and the need to mitigate the risks associated with faulty electronic components.

The consumer electronics industry is a significant contributor to the in-circuit tester market. With the rapid development and launch of new consumer electronic devices, the demand for high-quality electronic components continues to rise. In-circuit testers are employed during the manufacturing process to detect defects and faults, ensuring that the final products meet the desired performance standards. The increasing consumer demand for smartphones, tablets, wearables, and smart home devices drives the need for efficient and accurate in-circuit testing.

The telecommunications industry heavily relies on electronic components for network infrastructure, communication devices, and data centers. In-circuit testers are crucial in this industry to validate the performance of electronic components and ensure the uninterrupted functioning of telecommunication systems. The ongoing advancements in 5G technology, network expansion, and the demand for high-speed connectivity drive the need for reliable in-circuit testing solutions.

The industrial sector encompasses various industries, including automation, robotics, machinery, and energy. In-circuit testers play a vital role in ensuring the quality and reliability of electronic components used in industrial applications. With the increasing adoption of Industrial Internet of Things (IIoT) technologies and automation, the demand for accurate and efficient in-circuit testing solutions is expected to grow.

Key Benefits for Industry Participants and Stakeholders

The global in-circuit tester market offers several benefits for industry participants and stakeholders:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the in-circuit tester market. While the initial phase of the pandemic led to disruptions in the global supply chain and manufacturing activities, the subsequent surge in remote working, online learning, and the increased adoption of electronic devices fueled the demand for in-circuit testers.

The pandemic highlighted the importance of robust and reliable electronic components, leading to an increased focus on quality control and testing. In-circuit testers played a crucial role in ensuring the proper functioning of electronic devices used for remote communication, healthcare, and other essential services.

Additionally, the integration of AI and ML algorithms into in-circuit testers allowed for remote testing and analysis, minimizing the need for physical presence in manufacturing facilities and ensuring continuity in the testing process during lockdowns and restrictions.

Key Industry Developments

Analyst Suggestions

Future Outlook

The global in-circuit tester market is expected to witness significant growth in the coming years. Technological advancements, integration of AI and ML, increasing adoption of IoT, and the emphasis on quality assurance and compliance are key factors driving market expansion.

The demand for in-circuit testers will continue to rise with the proliferation of electronic devices in sectors such as automotive, aerospace, consumer electronics, telecommunications, and industrial applications. The expansion of emerging markets and the focus on sustainable manufacturing practices present lucrative opportunities for market players.

Furthermore, the ongoing miniaturization of PCBs, the need for high-speed testing, and the integration of data analytics capabilities will shape the future of the in-circuit tester market. Manufacturers that prioritize research and development, customer-centric approaches, and strategic collaborations will be well-positioned to capitalize on these trends and achieve sustainable growth.

Conclusion

The global in-circuit tester market is witnessing steady growth due to the increasing demand for electronic devices and the need for reliable testing solutions. Despite challenges such as complex testing procedures and high initial investments, the market presents opportunities in emerging economies, IoT integration, collaborations, and sustainable manufacturing practices.

Technological advancements, including AI and ML integration, Industry 4.0 adoption, and the emphasis on data analytics, are shaping the market’s future. The Covid-19 pandemic has highlighted the importance of in-circuit testers in ensuring quality control and reliability of electronic components.

To succeed in this competitive landscape, manufacturers need to focus on continuous research and development, customization, strategic collaborations, and training programs. By aligning with industry trends and customer requirements, in-circuit tester manufacturers can achieve long-term success and contribute to the growth of the global electronics industry.

What is In circuit Tester?

In circuit testers are devices used to test electronic circuits for faults and ensure proper functionality. They are commonly employed in manufacturing and repair processes to verify the integrity of printed circuit boards and other electronic components.

What are the key players in the Global In circuit Tester Market?

Key players in the Global In circuit Tester Market include companies like Keysight Technologies, Teradyne, and National Instruments, which provide advanced testing solutions for various electronic applications, among others.

What are the growth factors driving the Global In circuit Tester Market?

The Global In circuit Tester Market is driven by the increasing demand for electronic devices, the rise of automation in manufacturing, and the need for quality assurance in production processes. These factors contribute to the growing adoption of in circuit testing technologies across various industries.

What challenges does the Global In circuit Tester Market face?

The Global In circuit Tester Market faces challenges such as the high initial investment costs for advanced testing equipment and the rapid pace of technological change, which can lead to obsolescence. Additionally, the complexity of modern electronic circuits can complicate testing processes.

What opportunities exist in the Global In circuit Tester Market?

Opportunities in the Global In circuit Tester Market include the expansion of the Internet of Things (IoT) and the growing demand for electric vehicles, which require sophisticated testing solutions. Furthermore, advancements in testing technology present avenues for innovation and market growth.

What trends are shaping the Global In circuit Tester Market?

Trends shaping the Global In circuit Tester Market include the integration of artificial intelligence in testing processes, the shift towards automated testing solutions, and the increasing focus on miniaturization of electronic components. These trends are enhancing testing efficiency and accuracy.

Global In-Circuit Tester Market Segmentation

| Segmentation Details | Information |

|---|---|

| Type | Functional Testers, In-Circuit Testers, Flying Probe Testers |

| Application | Aerospace & Defense, Automotive, Consumer Electronics, Healthcare, Others |

| Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global In-Circuit Tester Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at