444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The global explosion protection market is witnessing significant growth due to the increasing emphasis on industrial safety measures across various sectors. Explosion protection refers to the measures taken to prevent and mitigate the risks associated with explosions in hazardous environments. These environments can be found in industries such as oil and gas, chemicals, mining, pharmaceuticals, and manufacturing.

Meaning

Explosion protection involves the implementation of safety measures and technologies to minimize the occurrence and impact of explosions. It encompasses various strategies, including explosion-proof equipment, hazardous area classification, flameproofing, intrinsically safe systems, and explosion isolation techniques. The goal is to protect both personnel and critical assets from explosions, which can result in severe injuries, loss of life, and significant financial damage.

Executive Summary

The global explosion protection market is projected to experience substantial growth in the coming years. Factors such as stringent government regulations, growing awareness about workplace safety, and the need for effective risk management are driving the market’s expansion. Additionally, the rising adoption of explosion-proof equipment and advancements in explosion protection technologies are further fueling market growth.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

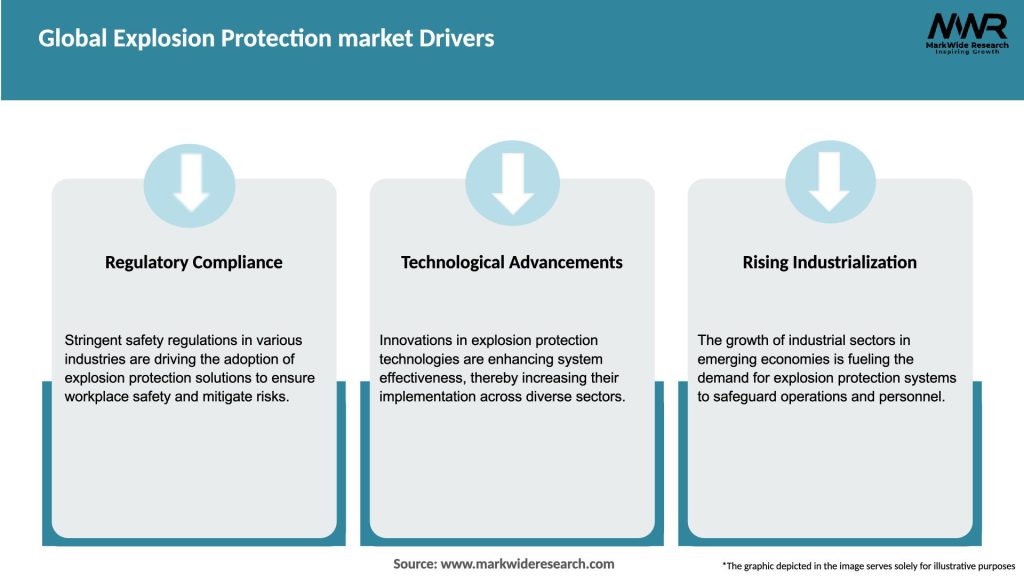

The global explosion protection market is driven by several key dynamics, including regulatory requirements, technological advancements, industry growth, and safety awareness. These factors interact to shape the market landscape and present opportunities and challenges for industry participants.

Regulatory requirements play a vital role in driving the adoption of explosion protection solutions. Governments and regulatory bodies have implemented stringent safety regulations to protect workers and prevent accidents in hazardous environments. Compliance with these regulations has become mandatory for industries, driving the demand for explosion protection measures.

Technological advancements have revolutionized the explosion protection market, enabling the development of more efficient and reliable solutions. Improved sensors, advanced monitoring systems, and smart devices have enhanced safety standards and reduced the risk of explosions. These technological innovations are driving market growth and opening up new opportunities for industry players.

The growth of industries such as oil and gas, chemicals, mining, pharmaceuticals, and manufacturing fuels the demand for explosion protection solutions. As these sectors expand, the need for robust safety measures becomes imperative to protect personnel and assets from potential explosions.

Increased safety awareness among industry players is another driving force behind the market’s growth. Organizations are realizing the potential risks associated with explosions and are proactively investing in preventive measures. This awareness, combined with the growing emphasis on workplace safety, is boosting the adoption of explosion protection solutions.

However, certain challenges can hamper market growth. The high upfront costs associated with implementing explosion protection measures can act as a barrier, especially for small and medium-sized enterprises (SMEs) or companies operating on tight budgets. The complexity of compliance requirements and the shortage of skilled workforce in the field of explosion protection also pose challenges for industries.

Despite these challenges, the market presents significant opportunities. The emphasis on renewable energy, technological innovations, emerging industries, and the growth of developing regions provide avenues for market expansion. By capitalizing on these opportunities and addressing the challenges effectively, industry participants can achieve sustained growth in the explosion protection market.

Regional Analysis

The explosion protection market can be analyzed based on regional segmentation, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has unique characteristics and market dynamics that influence the adoption of explosion protection solutions.

North America: North America is a significant market for explosion protection, driven by stringent safety regulations and the presence of well-established industries. The United States and Canada have implemented strict safety standards, making explosion protection measures mandatory for industries operating in hazardous environments. The region’s focus on advanced technologies and safety consciousness contributes to market growth.

Europe: Europe is witnessing significant growth in the explosion protection market, attributed to stringent safety regulations and the presence of key industries such as chemicals, oil and gas, and pharmaceuticals. The European Union (EU) has implemented directives and standards to ensure workplace safety, driving the adoption of explosion protection measures. Technological advancements and a focus on sustainable energy solutions further boost market growth in the region.

Asia Pacific: Asia Pacific is a rapidly growing market for explosion protection, fueled by the region’s rapid industrialization and infrastructure development. Countries like China, India, and Japan are experiencing substantial growth in industries such as manufacturing, oil and gas, and mining. The increasing emphasis on workplace safety and compliance with international safety standards drive the demand for explosion protection solutions in this region.

Latin America: Latin America presents significant opportunities for the explosion protection market due to the growth of industries such as oil and gas, mining, and chemicals. Countries like Brazil, Mexico, and Argentina have seen investments in infrastructure projects and industrial expansion, leading to an increased demand for explosion protection measures. The implementation of safety regulations and the need for risk mitigation further contribute to market growth.

Middle East and Africa: The Middle East and Africa region have a strong presence of industries such as oil and gas, petrochemicals, and mining, which are prone to explosion risks. The stringent safety regulations implemented by countries in the region drive the adoption of explosion protection measures. The region’s focus on safety and the presence of major oil-producing countries contribute to market growth.

The regional analysis highlights the diverse market dynamics and opportunities present in each region. Understanding these dynamics is crucial for industry participants to develop targeted strategies and tap into the potential of different markets.

Competitive Landscape

Leading companies in the Global Explosion Protection Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The global explosion protection market can be segmented based on various factors, including type of protection method, end-user industry, and geography.

By Protection Method:

By End-User Industry:

By Geography:

Segmenting the market allows for a better understanding of customer requirements and market trends. It helps industry participants tailor their offerings to specific segments and regions, maximizing their market penetration and growth potential.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding the strengths, weaknesses, opportunities, and threats helps industry participants identify areas for improvement, capitalize on growth opportunities, and mitigate potential risks and challenges in the market.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the global explosion protection market. The pandemic led to disruptions in various industries, supply chain challenges, and a slowdown in economic activities. However, the impact on the explosion protection market has been relatively moderate, with both positive and negative effects observed.

Positive Impact:

Negative Impact:

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the global explosion protection market is promising. The market is expected to continue growing due to the increasing emphasis on workplace safety, stringent regulations, and technological advancements. As industries continue to prioritize risk management and safety measures, the demand for explosion protection solutions will remain robust.Technological advancements, such as IoT, AI, and ML, will play a significant role in shaping the future of the market. Integration of these technologies will enable advanced monitoring, predictive maintenance, and real-time data analysis, enhancing the effectiveness and efficiency of explosion protection systems. Companies that invest in research and development, focus on customization and tailored solutions, and maintain compliance with regulations will be well-positioned to capitalize on market opportunities. Collaboration and partnerships with other industry players and stakeholders will also contribute to innovation and market growth. However, challenges such as high upfront costs, complex compliance requirements, and the shortage of skilled workforce will need to be addressed. Industry participants should find innovative solutions to overcome these challenges and ensure the effective implementation and maintenance of explosion protection measures.

Conclusion

In conclusion, the global explosion protection market is poised for growth in the coming years. The market will be driven by increasing safety awareness, stringent regulations, technological advancements, and the expansion of industries. By embracing opportunities, addressing challenges, and staying at the forefront of innovation, industry participants can thrive in this dynamic market and contribute to safer work environments globally. With continuous innovation, collaboration, and a focus on meeting customer needs, industry participants can thrive in this dynamic market and contribute to safer work environments worldwide. The market presents both opportunities and challenges. The emphasis on renewable energy, technological innovations, emerging industries, and the growth of developing regions creates avenues for market expansion. However, high upfront costs, complex compliance requirements, and the shortage of skilled workforce can hinder market growth.

What is Explosion Protection?

Explosion Protection refers to the methods and technologies used to prevent explosions in hazardous environments. This includes the use of specialized equipment, safety protocols, and design strategies to mitigate risks associated with flammable materials and gases.

What are the key players in the Global Explosion Protection market?

Key players in the Global Explosion Protection market include companies like Honeywell, Siemens, and ABB, which provide a range of explosion-proof equipment and solutions for various industries, including oil and gas, chemicals, and mining, among others.

What are the main drivers of the Global Explosion Protection market?

The main drivers of the Global Explosion Protection market include the increasing demand for safety regulations in industries handling flammable materials, the growth of the oil and gas sector, and advancements in technology that enhance safety measures.

What challenges does the Global Explosion Protection market face?

Challenges in the Global Explosion Protection market include the high costs associated with implementing safety measures, the complexity of compliance with various regulations, and the need for continuous innovation to keep up with evolving industry standards.

What opportunities exist in the Global Explosion Protection market?

Opportunities in the Global Explosion Protection market include the expansion of industries in emerging economies, the development of smart explosion protection systems, and the increasing focus on sustainability and environmental safety.

What trends are shaping the Global Explosion Protection market?

Trends shaping the Global Explosion Protection market include the integration of IoT technologies for real-time monitoring, the rise of automation in hazardous environments, and the growing emphasis on employee safety and training programs.

Global Explosion Protection market

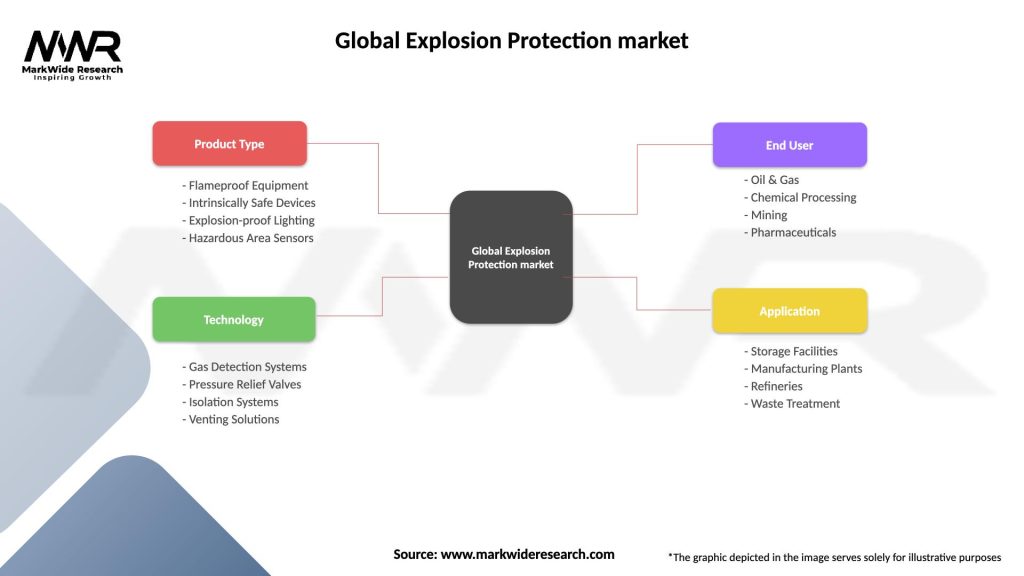

| Segmentation Details | Description |

|---|---|

| Product Type | Flameproof Equipment, Intrinsically Safe Devices, Explosion-proof Lighting, Hazardous Area Sensors |

| Technology | Gas Detection Systems, Pressure Relief Valves, Isolation Systems, Venting Solutions |

| End User | Oil & Gas, Chemical Processing, Mining, Pharmaceuticals |

| Application | Storage Facilities, Manufacturing Plants, Refineries, Waste Treatment |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Global Explosion Protection Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at