444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The global continuous extrusion machine market is expected to witness significant growth over the forecast period. The market is being driven by the increasing demand for continuous extrusion machines in various industries such as automotive, aerospace, and construction. Continuous extrusion machines are used to produce high-quality products with high efficiency and accuracy, which is contributing to their popularity. Additionally, the rising demand for lightweight materials and the increasing use of automation in manufacturing are also driving the growth of the market.

Continuous extrusion machines are used to create long, continuous profiles of materials such as plastics, metals, and ceramics. These machines use a continuous feed system to create a consistent output, making them ideal for large-scale production. They are used in a variety of industries, including automotive, aerospace, construction, and electronics, to create products such as pipes, wires, and cables.

In this report, we will analyze the global continuous extrusion machine market, examining the market’s current state, key trends, drivers, restraints, opportunities, and future outlook. We will also provide a SWOT analysis, competitive landscape analysis, and regional analysis of the market.

Meaning

Continuous extrusion machines are used to produce long, continuous profiles of materials such as plastics, metals, and ceramics. These machines use a continuous feed system to create a consistent output, making them ideal for large-scale production. They are used in a variety of industries, including automotive, aerospace, construction, and electronics, to create products such as pipes, wires, and cables.

The machine consists of a barrel, a screw, and a die. The material is fed into the barrel, where it is heated and melted. The screw then pushes the molten material through the die, which shapes it into the desired profile. The extruded material is then cooled and cut to the desired length.

Continuous extrusion machines offer several advantages over other types of extrusion machines. They are capable of producing long, continuous profiles with high efficiency and accuracy, and can produce products with a high level of consistency. Additionally, they require less maintenance than other types of machines, and are often more cost-effective in the long run.

Executive Summary

The global continuous extrusion machine market is expected to witness significant growth over the forecast period. The market is being driven by the increasing demand for continuous extrusion machines in various industries such as automotive, aerospace, and construction. Continuous extrusion machines are used to produce high-quality products with high efficiency and accuracy, which is contributing to their popularity. Additionally, the rising demand for lightweight materials and the increasing use of automation in manufacturing are also driving the growth of the market.

The market is expected to grow at a CAGR of XX% during the forecast period (2023-2028), reaching a market size of USD XX billion by 2028. The increasing adoption of automation in manufacturing, coupled with the rising demand for lightweight materials, is expected to drive the growth of the market.

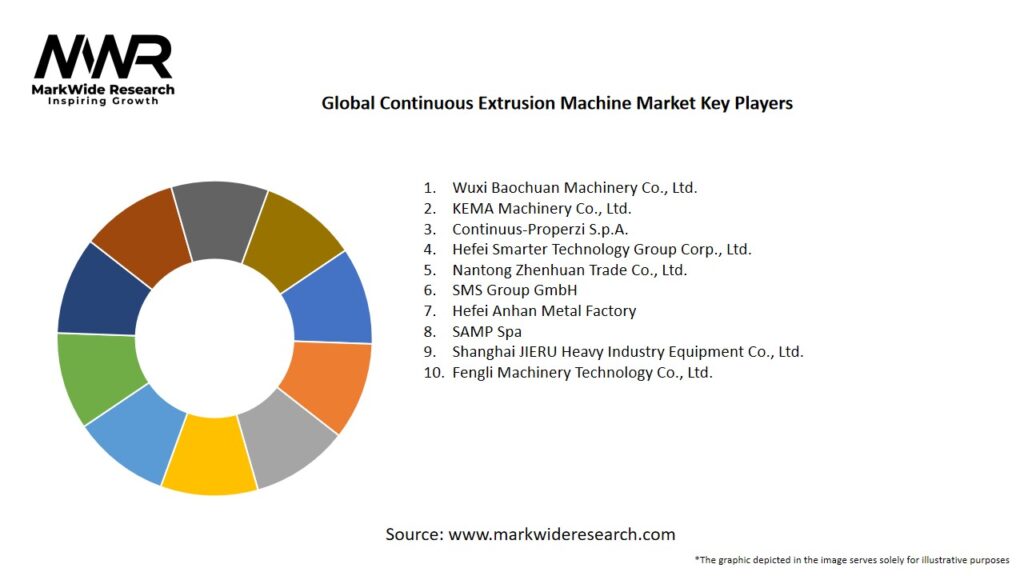

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The Global Continuous Extrusion Machine Market is driven by several factors:

Demand for High-Efficiency Production Systems: Continuous extrusion machines offer higher production rates, better material utilization, and lower energy consumption, making them an attractive option for industries seeking to improve manufacturing efficiency.

Expansion of End-User Industries: Industries such as construction (for pipe and profile production), packaging (for films and sheets), automotive (for parts and components), and food processing (for extrusion of snacks and pasta) are contributing significantly to the demand for continuous extrusion machines.

Technological Innovation: Advances in extrusion technology, such as improved control systems, automation, and energy-saving features, are enhancing the appeal of continuous extrusion machines by reducing downtime and improving the consistency of the produced material.

Customization and Versatility: The increasing demand for customized products, such as various plastic profiles, films, and food products, is driving the adoption of continuous extrusion machines that offer flexibility and the ability to meet diverse production requirements.

Market Restraints

Despite the growth potential, the Global Continuous Extrusion Machine Market faces several challenges:

High Initial Investment: The cost of setting up continuous extrusion machines, particularly those equipped with advanced automation and control systems, can be a significant barrier for small and medium-sized enterprises (SMEs) looking to enter the market.

Complex Maintenance: Continuous extrusion machines require regular maintenance and technical expertise, which can add operational costs and reduce the overall efficiency of the production process.

Competition from Alternative Technologies: Alternative manufacturing technologies, such as injection moulding or blow moulding, may offer advantages in specific applications, potentially limiting the market share of continuous extrusion machines in certain industries.

Material Limitations: While continuous extrusion is versatile, certain materials may be challenging to extrude continuously, limiting the types of products that can be efficiently produced using this technology.

Market Opportunities

The Global Continuous Extrusion Machine Market presents several opportunities for growth:

Advancements in Automation: The increasing adoption of automation technologies, including AI and robotics, provides opportunities for continuous extrusion machines to become more efficient, customizable, and cost-effective, thereby improving the competitive edge of manufacturers.

Energy-Efficient Solutions: As industries strive to reduce energy consumption and lower operational costs, the development of more energy-efficient continuous extrusion machines presents significant market opportunities for manufacturers.

Emerging Markets: Emerging markets in Asia-Pacific, Latin America, and Africa are expected to see substantial growth in manufacturing and industrial activities, creating new opportunities for the adoption of continuous extrusion machines.

Sustainability and Eco-Friendly Materials: With the growing focus on sustainability and eco-friendly materials, there is increasing demand for extrusion machines capable of processing biodegradable plastics, recycled materials, and plant-based food ingredients.

Market Dynamics

The Global Continuous Extrusion Machine Market is influenced by several dynamic factors:

Technological Advancements: The market is constantly evolving with the integration of new technologies aimed at improving the efficiency, speed, and versatility of continuous extrusion machines. Innovations in control systems, automation, and real-time monitoring are contributing to the market’s growth.

Rising Demand for Customization: As consumer preferences shift toward more customized and unique products, industries are turning to continuous extrusion machines to meet these demands. The ability to create a wide range of shapes, sizes, and materials makes extrusion technology highly adaptable.

Regulatory Factors: Stricter environmental regulations, particularly related to energy consumption, waste reduction, and material sustainability, are influencing the development of more eco-friendly and energy-efficient extrusion systems.

Industry-Specific Applications: Different industries, including automotive, packaging, construction, and food processing, have specific needs for continuous extrusion machines, which are shaping the demand for specialized machines and solutions.

Regional Analysis

The Global Continuous Extrusion Machine Market shows regional variations in demand and growth:

North America: North America, particularly the U.S., is a leading market for continuous extrusion machines, driven by the growing demand in industries such as food processing, automotive, and packaging. The region’s focus on technological innovation and automation also supports market growth.

Europe: Europe has a well-established manufacturing industry, with a strong demand for continuous extrusion machines in the automotive, construction, and packaging sectors. The region is also witnessing a shift toward sustainable production processes, driving the demand for energy-efficient extrusion systems.

Asia-Pacific: The Asia-Pacific region is expected to experience the highest growth rate, primarily due to the rapid industrialization, expanding manufacturing activities, and increasing demand for customized products in emerging economies such as China, India, and Southeast Asia.

Latin America and Middle East & Africa: The market in these regions is growing steadily as industrial development accelerates, particularly in countries like Brazil, Mexico, and Saudi Arabia. The demand for continuous extrusion machines in construction, packaging, and food processing is on the rise.

Competitive Landscape

Leading Companies in the Global Continuous Extrusion Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

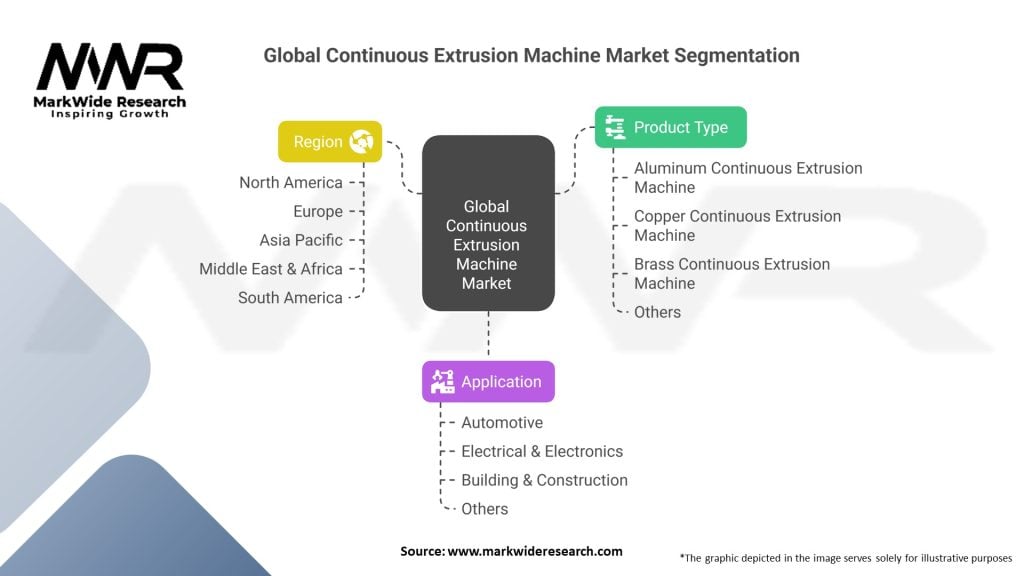

The Global Continuous Extrusion Machine Market can be segmented based on:

Type: Single Screw Extrusion, Twin Screw Extrusion.

Material Type: Plastics, Metals, Food Ingredients, Others.

End-User Industry: Food Processing, Packaging, Automotive, Construction, Pharmaceuticals, Others.

Category-wise Insights

Each category offers unique opportunities for growth:

Key Benefits for Industry Participants and Stakeholders

The Continuous Extrusion Machine Market offers several benefits for industry participants:

Cost Savings: Continuous extrusion machines improve production efficiency, reduce material waste, and lower operational costs.

Enhanced Production Capabilities: The ability to produce high volumes of uniform products with minimal downtime improves overall operational productivity.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Key trends shaping the Continuous Extrusion Machine Market include:

Technological Advancements: Ongoing improvements in automation, energy efficiency, and machine versatility are driving market growth.

Sustainability Focus: The demand for eco-friendly and energy-efficient extrusion systems is on the rise as industries focus on reducing their environmental impact.

Covid-19 Impact

The global continuous extrusion machine market has been impacted by the Covid-19 pandemic, with several key players in the market experiencing supply chain disruptions and a decline in demand. However, the market is expected to recover in the coming years, driven by the increasing adoption of automation in manufacturing and the rising demand for sustainable production methods.

Key Industry Developments

Some of the key industry developments in the global continuous extrusion machine market include:

Analyst Suggestions

Analysts suggest that key players in the global continuous extrusion machine market should focus on developing innovative products and expanding their market presence through strategic partnerships and collaborations. Additionally, companies should focus on developing sustainable production methods and integrating continuous extrusion machines with other automated systems to improve efficiency and reduce labor costs.

Future Outlook

The global continuous extrusion machine market is expected to grow at a CAGR of XX% over the forecast period, reaching a market size of USD XX billion by 2028. The market is being driven by several key factors, including the increasing demand for high-quality products, the rising demand for lightweight materials, and the increasing use of automation in manufacturing.

Additionally, the growing need for cost-effective production processes is also driving the growth of the market. While the market is expected to face several challenges over the forecast period, such as the high cost of continuous extrusion machines and the availability of alternative production methods, there are also several opportunities for growth.

Some of the key opportunities for growth in the market include the increasing demand for sustainable production methods and the growing demand for automation in manufacturing.

Conclusion

In conclusion, the Global Continuous Extrusion Machine Market offers strong growth prospects, fueled by advancements in technology, rising industrial demand, and a focus on energy efficiency. Companies that prioritize innovation and sustainability will be well-positioned to capitalize on the growing demand for efficient, high-performance extrusion systems.

What is a continuous extrusion machine?

A continuous extrusion machine is a type of industrial equipment used to process materials, typically plastics or metals, by forcing them through a die to create a continuous profile. This technology is widely utilized in various applications, including the production of pipes, sheets, and profiles in the manufacturing sector.

Who are the key players in the Global Continuous Extrusion Machine Market?

Key players in the Global Continuous Extrusion Machine Market include companies such as KraussMaffei, Coperion, and Milacron, which are known for their advanced extrusion technologies and solutions. These companies compete on innovation, efficiency, and customer service, among others.

What are the main drivers of growth in the Global Continuous Extrusion Machine Market?

The main drivers of growth in the Global Continuous Extrusion Machine Market include the increasing demand for lightweight materials in automotive and aerospace industries, advancements in extrusion technology, and the rising need for efficient manufacturing processes. Additionally, the expansion of the packaging industry is also contributing to market growth.

What challenges does the Global Continuous Extrusion Machine Market face?

The Global Continuous Extrusion Machine Market faces challenges such as high initial investment costs and the need for skilled labor to operate complex machinery. Furthermore, fluctuations in raw material prices can impact production costs and profitability.

What opportunities exist in the Global Continuous Extrusion Machine Market?

Opportunities in the Global Continuous Extrusion Machine Market include the growing trend towards sustainable manufacturing practices and the development of bio-based materials. Additionally, the increasing adoption of automation and Industry Four Point Zero technologies presents new avenues for growth.

What trends are shaping the Global Continuous Extrusion Machine Market?

Trends shaping the Global Continuous Extrusion Machine Market include the integration of smart technologies for enhanced process control and efficiency, as well as the rising demand for customized extrusion solutions. Moreover, the focus on reducing waste and improving energy efficiency is becoming increasingly important in the industry.

Global Continuous Extrusion Machine Market

| Segmentation | Details |

|---|---|

| Product Type | Aluminum Continuous Extrusion Machine, Copper Continuous Extrusion Machine, Brass Continuous Extrusion Machine, Others |

| Application | Automotive, Electrical & Electronics, Building & Construction, Others |

| Region | North America, Europe, Asia Pacific, Middle East & Africa, South America |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Continuous Extrusion Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at