Key Market Insights

-

The commercial vehicle segment accounts for over 60% of global leaf spring demand, with heavy-duty trucks and buses as primary end-users.

-

Composite leaf springs are projected to grow at a double-digit rate, driven by up to 40% weight savings compared to steel variants.

-

Replacement and aftermarket services represent a stable revenue stream in mature regions, supported by extended fleet lifecycles and maintenance programs.

-

Automated manufacturing techniques, such as robotic forging and laser trimming, are improving spring precision and reducing production costs.

-

Stringent emission and fuel-efficiency regulations in Europe and North America are accelerating adoption of lightweight spring technologies.

Market Drivers

-

Commercial Vehicle Growth: Expansion of e-commerce and regional trade has increased demand for trucks and buses, boosting leaf spring requirements.

-

Infrastructure Development: Investments in highways and urban mass transit systems in emerging economies drive bus and truck sales, supporting spring volumes.

-

Weight Reduction Initiatives: OEM targets for improved fuel efficiency and lower CO₂ emissions incentivize the use of composite and multi-leaf ultra-light designs.

-

Aftermarket Replacement: Aging fleets in North America and Europe maintain steady aftermarket demand for steel replacement springs and performance upgrades.

-

Cost-Effectiveness: Steel leaf springs remain a low-cost suspension choice, particularly in price-sensitive markets where advanced suspensions are less viable.

Market Restraints

-

Competition from Alternative Suspensions: Coil springs and air suspension systems offer superior ride comfort and tunability, reducing leaf spring penetration in passenger vehicles.

-

High Upfront Costs: Composite spring development and tooling costs remain high, limiting adoption to premium or regulated segments.

-

Material Supply Volatility: Fluctuations in steel and fiber-reinforced polymer prices can affect manufacturing costs and pricing stability.

-

Limited Passenger Vehicle Use: Leaf springs are rare in modern passenger cars, restricting market expansion to commercial and specialty vehicles.

-

Maintenance Perceptions: Some fleet operators perceive leaf springs as prone to sagging and require periodic re-arching, despite advances in design.

Market Opportunities

-

Composite Material Adoption: Broader deployment of glass and carbon-fiber composites offers weight savings and corrosion resistance, capturing OEM interest.

-

Electric Commercial Vehicles: Growth of electric trucks and buses creates niche for composite springs to offset heavy battery weights and extend range.

-

Retrofitting Programs: Upgrading aging fleets with modern, high-strength steel or composite springs can improve safety and reduce operating costs.

-

Regional Expansions: Infrastructure upgrades in Southeast Asia, Africa, and Latin America will open new markets for both OEM and aftermarket spring suppliers.

-

Integrated Suspension Systems: Partnerships between spring and shock-absorber manufacturers to deliver complete axle assemblies can streamline purchasing and installation

Market Dynamics

-

OEM vs. Aftermarket Channels: OEMs drive new-vehicle spring demand, while aftermarket distributors and service centers capture replacement and upgrade revenue.

-

Technology Partnerships: Collaborations between material science firms and tier-1 suppliers are key to developing cost-effective composite solutions.

-

Regulatory Pressures: Emission and fuel-efficiency standards are indirectly shaping spring design through weight reduction targets and vehicle downsizing.

-

Digital Manufacturing: Industry 4.0 adoption—IoT-connected machinery and predictive maintenance—enhances production efficiency and reduces downtime.

-

Competitive Pricing: Low-cost steel spring producers in Asia Pacific apply price competitiveness to capture share in emerging and mature markets alike.

Regional Analysis

-

Asia-Pacific: Dominant region, led by China’s and India’s growing commercial vehicle fleets; local steel suppliers and emerging composite producers drive cost advantages.

-

North America: Steady aftermarket demand and early adoption of composite leaf springs for vocational and Class 8 trucks; investments in automation improve domestic manufacturing.

-

Europe: Moderate volume growth, with focus on emission compliance and lightweighting; German and Scandinavian OEMs pilot composite springs on electric buses.

-

Latin America: Replacement market bolstered by older fleets; Brazil and Mexico lead OEM adoption in medium-duty trucks and agricultural equipment.

-

Middle East & Africa: Infrastructure projects and mining operations spur heavy-duty spring demand; high corrosion environments favor composite alternatives.

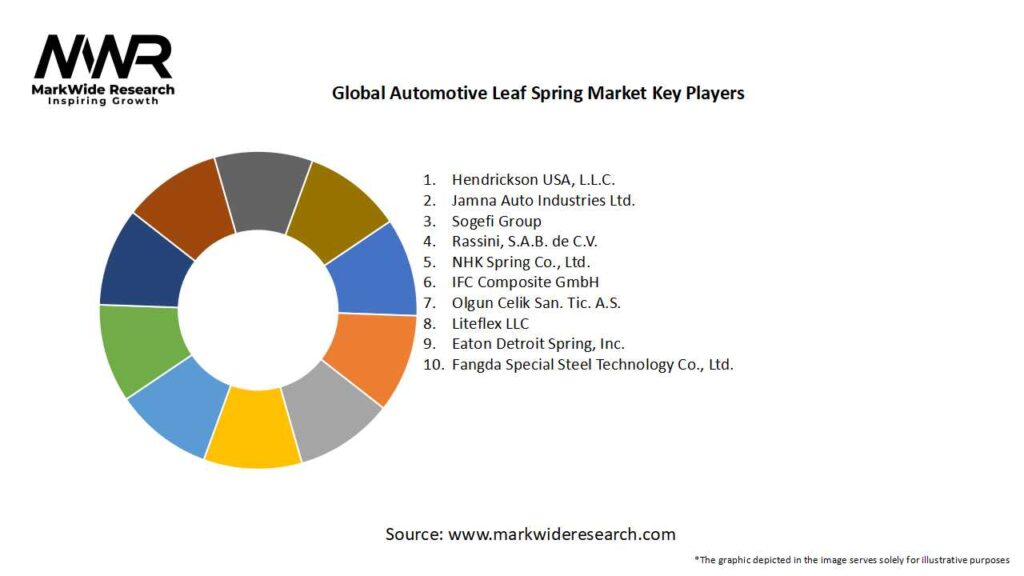

Competitive Landscape

Leading Companies in the Global Automotive Leaf Spring Market:

- Hendrickson USA, L.L.C.

- Jamna Auto Industries Ltd.

- Sogefi Group

- Rassini, S.A.B. de C.V.

- NHK Spring Co., Ltd.

- IFC Composite GmbH

- Olgun Celik San. Tic. A.S.

- Liteflex LLC

- Eaton Detroit Spring, Inc.

- Fangda Special Steel Technology Co., Ltd.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

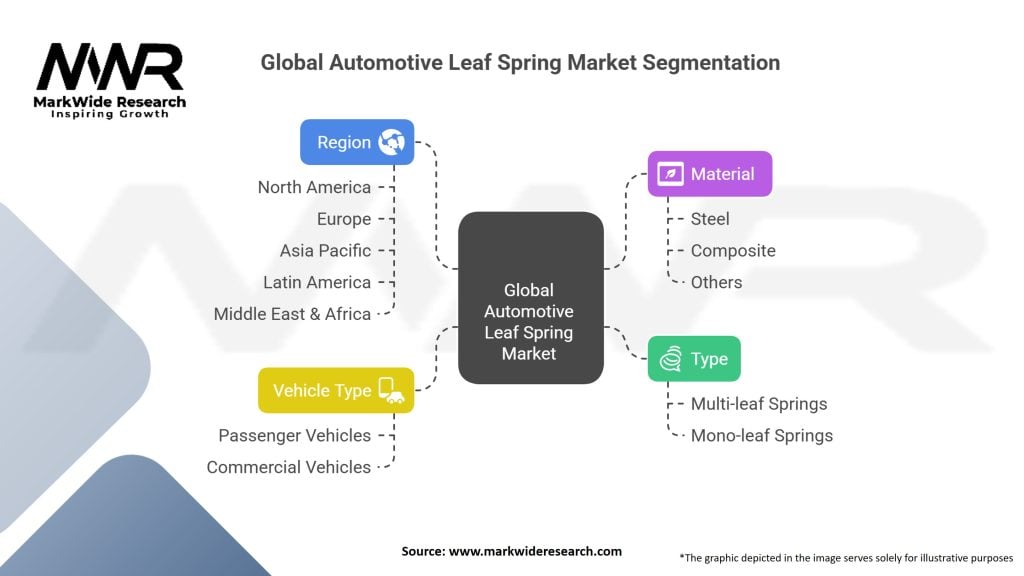

Segmentation

-

By Material: Hot-Rolled Steel, High-Strength Alloy Steel, Composite (Glass-Fiber, Carbon-Fiber)

-

By Vehicle Type: Light Commercial Vehicles, Heavy Trucks, Buses & Coaches, Trailers & Semi-Trailers, Off-Road & Agricultural Vehicles

-

By Leaf Configuration: Single-Leaf, Multi-Leaf, Parabolic Leaf Springs

-

By Sales Channel: OEM Supply, Aftermarket Replacement, Retrofitting Services

Category-wise Insights

-

Hot-Rolled Steel Springs: Economical and robust; favored in heavy-duty and high-impact applications despite higher weight.

-

High-Strength Alloy Springs: Offer moderate weight reduction and improved fatigue life; common in premium commercial vehicles.

-

Parabolic Multi-Leaf Springs: Profiled leaves deliver improved ride comfort and reduced inter-leaf friction, bridging gap to coil springs.

-

Glass-Fiber Composite Springs: Provide up to 30% weight savings; gaining traction in European bus and coach markets.

-

Carbon-Fiber Composite Springs: Ultra-light and high-strength; pilot projects in electric urban transit vehicles demonstrate performance gains.

Key Benefits for Industry Participants and Stakeholders

-

Enhanced Payload Capacity: High-strength materials and optimized designs yield greater load-bearing capacity without weight penalty.

-

Fuel Efficiency Gains: Weight reduction translates directly to lower fuel consumption and emissions, meeting corporate sustainability goals.

-

Reduced Maintenance Costs: Composite springs resist corrosion and fatigue longer, lowering life-cycle maintenance expenses.

-

Simplified Vehicle Architecture: Parabolic and composite springs can integrate axle location, eliminating separate linkage components.

-

Stable Revenue Streams: Aftermarket and retrofitting services provide predictable income to manufacturers and distributors.

SWOT Analysis

Strengths:

-

Proven, reliable suspension technology with decades of application.

-

Low cost of basic steel springs ensures affordability.

-

New materials and designs maintain market relevance.

Weaknesses:

-

Heavier than coil and air suspensions, limiting use in certain segments.

-

Composite spring adoption hampered by high initial investment.

-

Limited passenger vehicle penetration.

Opportunities:

-

Rising electric commercial vehicle adoption opens composite spring niche.

-

Infrastructure growth in emerging regions expands fleet sizes.

-

Technological convergence with smart sensors for condition monitoring.

Threats:

-

Shift toward advanced suspension systems in premium and luxury segments.

-

Volatility in raw material prices affecting production costs.

-

Regulatory changes favoring alternative suspension technologies.

Market Key Trends

-

Parabolic Leaf Spring Adoption: Enhanced ride comfort and reduced weight are driving parabolic designs in medium-duty vehicles.

-

Composite Material Integration: Upsurge in glass-fiber and carbon-fiber springs as OEMs seek lightweight solutions for electric buses.

-

Digital Quality Control: Use of laser scanning and machine-vision to ensure consistent spring curvature and performance.

-

Service-Based Models: OEMs offering “suspension as a service” packages that include periodic spring inspections and replacements.

-

Condition Monitoring: Embedding strain gauges and IoT modules in springs for real-time health diagnostics.

Covid-19 Impact

The pandemic temporarily disrupted supply chains, leading to steel and polymer shortages that constrained production. However, accelerated growth in e-commerce increased freight volumes, bolstering demand for commercial vehicles and their components. Aftermarket spring replacements also rose as fleets deferred full servicing in favor of essential maintenance. The crisis underscored the value of durable composite springs that reduce downtime and dependency on complex supply networks.

Key Industry Developments

-

Carlisle introduced a robotic forging line in 2023, doubling capacity for high–strength alloy springs.

-

SAF-HOLLAND launched integrated axle-spring modules featuring parabolic leaf springs and dampers for North American trailers.

-

JK Fenner partnered with a European polymer firm to pilot carbon-fiber leaf springs on electric delivery vans in India.

-

Hendrickson expanded its composite spring R&D center in Michigan to accelerate lightweight suspension solutions for EVs.

Analyst Suggestions

-

Invest in Composite R&D: Scale production capabilities for glass-fiber and carbon-fiber springs to reduce per-unit costs.

-

Forge OEM Partnerships: Collaborate with electric bus and truck manufacturers to secure composite spring adoption in next-gen vehicle platforms.

-

Expand Aftermarket Services: Develop retrofit kits and service packages targeting aging fleets in mature regions.

-

Leverage Industry 4.0: Implement predictive maintenance analytics through IoT-equipped springs to differentiate offerings.

-

Monitor Alternative Suspensions: Track coil and air suspension adoption in adjacent segments to adapt product portfolios proactively.

Future Outlook

The Global Automotive Leaf Spring market is set to maintain stable growth through 2030, anchored by commercial vehicle expansion and replacement demand. While traditional steel springs will continue to serve cost-sensitive applications, composite and parabolic designs will gain share in premium and electric vehicle segments. Digital manufacturing and condition-monitoring technologies will further enhance spring reliability and performance. Manufacturers that balance material innovation with cost efficiency and service offerings will lead the next wave of market transformation.

Conclusion

In conclusion, leaf springs remain a cornerstone of heavy-duty vehicle suspensions, combining simplicity with load-bearing robustness. The market’s evolution toward lightweight composites, parabolic profiles, and smart-enabled designs ensures continued relevance amid a rapidly changing vehicle landscape. By aligning R&D, manufacturing, and service strategies with emerging trends—such as electrification and digital maintenance—industry participants can capture growth opportunities and deliver value across the global automotive ecosystem.