444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The Global Automotive Constant Vehicle Joint Boots Market is a thriving industry that plays a crucial role in ensuring the smooth functioning of vehicles. Constant vehicle joint boots, also known as CV joint boots, are essential components that protect the CV joints, which are responsible for transmitting power from the transmission to the wheels. This market report provides valuable insights into the current state and future prospects of the global automotive constant vehicle joint boots market.

Constant vehicle joint boots are flexible covers made of rubber or other durable materials that enclose the CV joints, protecting them from dust, debris, and moisture. These boots maintain the lubrication within the joint and prevent contamination, ensuring the longevity and optimal performance of the CV joints. In the automotive industry, CV joint boots are critical for maintaining the drivetrain integrity and overall vehicle reliability.

Executive Summary

The executive summary of the global automotive constant vehicle joint boots market highlights the key findings and essential information gathered from the comprehensive market analysis. It provides a concise overview of the market, including market size, growth rate, market trends, and key market players. The executive summary serves as a quick reference guide for industry participants and stakeholders interested in understanding the market dynamics and future opportunities.

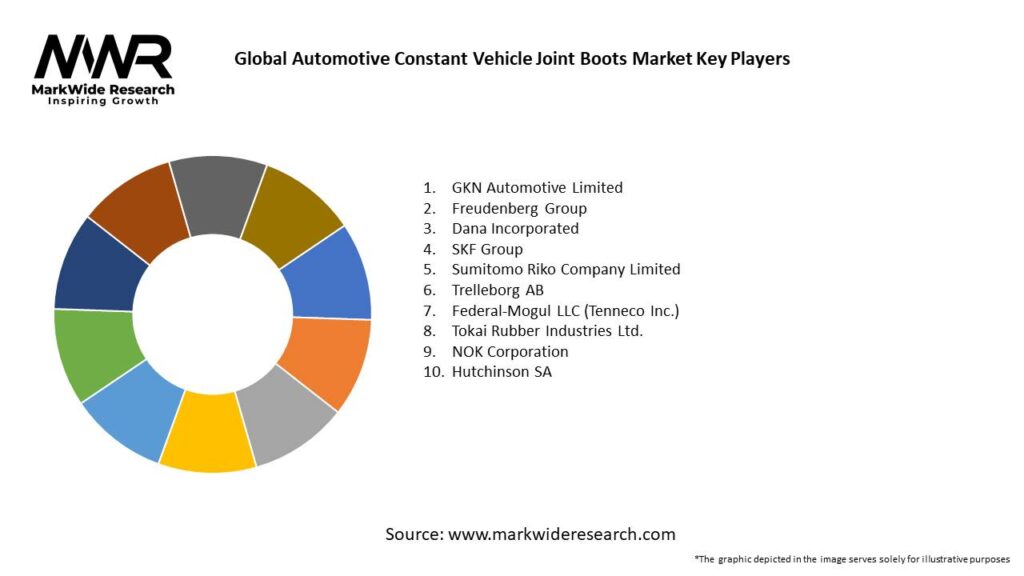

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Several critical insights provide the foundational understanding of the global automotive constant vehicle joint boots market:

Expanding Automotive Production: The continuous growth of the global automotive industry—especially in emerging markets—is a major driver of demand for high-performance CV joint boots. Increased vehicle production translates directly to higher demand in both original equipment manufacturing (OEM) and aftermarket segments.

Aftermarket Growth: The increasing lifespan of vehicles coupled with a strong aftermarket repair and replacement culture in many regions is boosting the demand for replacement CV joint boots. This segment is particularly strong in developed economies where maintenance and replacement of aging vehicle components are a priority.

Technological Advancements: Advances in material science and production technologies are leading to the development of CV joint boots that offer superior performance in terms of durability, heat resistance, and flexibility. Innovations such as reinforced and hybrid compounds are setting new performance benchmarks.

Safety and Reliability Requirements: With rising concerns for road safety and vehicle reliability, manufacturers are focusing on components that enhance overall vehicle performance and minimize maintenance costs. CV joint boots are critical to preventing joint failure, thereby ensuring safer vehicle operation.

Sustainability and Material Innovations: Growing environmental awareness is pushing manufacturers to adopt eco-friendly materials and sustainable production practices without compromising performance, thus influencing product development.

Economic Considerations: While demand is rising, fluctuations in raw material prices and production costs pose challenges that need to be managed through efficient supply chain practices and economies of scale.

Regulatory Landscape: Increasingly stringent quality and safety regulations across global markets are driving manufacturers to continually improve product designs and adhere to higher standards, ensuring long-term market growth.

These insights underscore the multifaceted influences that drive this market and reflect the interplay between technological, economic, and regulatory factors shaping its evolution.

Market Drivers

The global automotive constant vehicle joint boots market is propelled by a range of key factors:

Increased Global Vehicle Production: Rapid industrialization and economic growth in emerging markets such as China, India, and Brazil are leading to record-high automobile production volumes, thereby driving demand for high-quality CV joint boots both in OEM and aftermarket settings.

Growing Aftermarket Demand: As vehicles age, the need for maintenance and replacement components increases. A robust aftermarket sector ensures continuous demand for replacement joint boots, especially in regions with longer vehicle lifespans.

Technological Advancements in Materials: Innovations in polymer and elastomer technology have resulted in joint boots that offer higher resistance to wear, chemicals, and environmental degradation. The development of reinforced and hybrid materials increases the operational lifespan and performance of these components.

Heightened Safety Standards: With evolving safety regulations and consumer demands for reliable and durable vehicle components, automotive manufacturers and suppliers are prioritizing quality parts such as CV joint boots to reduce the risk of joint failure and ensure vehicle safety.

After-Sales Service Expansion: The growing emphasis on vehicle maintenance and service quality by both OEMs and independent repair centers is creating a strong aftermarket for replacement parts, including CV joint boots.

Sustainability Initiatives: As automotive companies focus on reducing their environmental footprint, there is a growing trend toward using more sustainable and recyclable materials. Developing eco-friendly CV joint boots can provide a competitive edge in a market increasingly governed by environmental regulations.

Global Supply Chain Expansion: Ongoing global trade and the establishment of efficient supply chain networks facilitate the distribution of high-quality automotive components to diverse markets, supporting overall market growth.

These drivers collectively contribute to robust market expansion by ensuring that CV joint boots remain indispensable components in vehicle assembly and maintenance.

Market Restraints

Despite strong market drivers, several challenges could potentially restrain the growth of the global automotive constant vehicle joint boots market:

High Production Costs: The production of high-performance joint boots involves significant investments in advanced materials and technology, leading to higher manufacturing costs which may affect the pricing dynamics, especially in cost-sensitive markets.

Raw Material Price Volatility: Fluctuations in the prices of raw materials, such as synthetic rubbers and specialized polymers, can impact overall production costs and profitability.

Integration Complexity: Automakers and suppliers may face challenges integrating new material technologies and product designs into existing production processes, which can delay product rollout or increase development time.

Intense Competition: The market is characterized by numerous global and regional players, leading to competitive pricing pressures and reduced margins. Continuous innovation is essential, but maintaining competitive advantage can be challenging.

Quality Control Issues: Maintaining consistent quality across production batches is critical; any variability can lead to performance issues and customer dissatisfaction, which may hinder market reputation.

Regulatory and Compliance Challenges: Varying regulatory requirements across different countries can result in delays and increased costs for global manufacturers, complicating market expansion strategies.

Economic Uncertainty: Global economic downturns or fluctuations in the automotive industry may reduce vehicle production and, consequently, the demand for CV joint boots.

Addressing these restraints effectively is essential for sustaining long-term market growth and ensuring that competitive pressures do not erode the advances made by technological innovation.

Market Opportunities

The global automotive constant vehicle joint boots market presents numerous opportunities for stakeholders:

Emerging Market Penetration: Rapid industrialization and increased vehicle production in emerging economies such as Asia-Pacific, Latin America, and Africa provide significant potential for expanding market share.

Innovative Product Development: Investment in advanced materials and manufacturing techniques can yield joint boots with enhanced performance characteristics (e.g., greater durability, improved flexibility, and increased environmental resistance), attracting a premium segment of the market.

Sustainability Initiatives: The move towards environmentally friendly automotive components presents an opportunity for manufacturers to develop eco-friendly CV joint boots that meet regulatory requirements and consumer expectations.

Aftermarket Growth: Expanding the aftermarket segment through strategic distribution and collaboration with independent service centers can drive significant revenue, as replacement parts are in constant demand for maintenance of aging vehicle fleets.

Advanced Manufacturing Technologies: Adoption of automation, robotics, and digital monitoring in the production of joint boots can enhance manufacturing efficiency, reduce waste, and lower production costs, thereby increasing market competitiveness.

Integration with Vehicle Safety Systems: Collaborating with automotive OEMs to integrate joint boots that complement advanced vehicle safety and monitoring systems could differentiate products and foster long-term supplier relationships.

Customization for Niche Applications: Developing specialized joint boots for electric vehicles (EVs), off-road vehicles, and luxury cars may open new market segments and contribute to revenue diversification.

By capitalizing on these opportunities, stakeholders can drive innovation, expand market reach, and enhance the overall value proposition of their products, ensuring sustainable growth in a competitive market.

Market Dynamics

The dynamics of the global automotive constant vehicle joint boots market are influenced by various supply-side and demand-side factors, in addition to economic and regulatory influences:

Supply Side Factors:

Innovative Manufacturing Processes: The adoption of advanced manufacturing methods such as injection molding automation and digital quality control systems is critical for producing high-quality joint boots efficiently.

R&D Investments: Continuous investment in research and development is driving improvements in material properties and product durability, facilitating the development of next-generation joint boots.

Raw Material Sourcing: Securing a stable supply of high-quality synthetic rubbers and polymers is essential for maintaining production efficiency and consistent product quality.

Technology Licensing: Partnerships and licensing deals that provide access to cutting-edge polymer formulations can enhance product performance and speed up market penetration.

Demand Side Factors:

Rising Production Volumes: Expanding global vehicle production, especially in emerging economies, is a major driver of demand for automotive components, including CV joint boots.

Safety and Reliability Requirements: Increasing emphasis on vehicle safety and longevity fuels demand for high-quality joint boots as they play a crucial role in maintaining the integrity of CV joints.

Maintenance and Aftermarket Services: Growing demand in the aftermarket segment is driven by the need to replace worn-out components in older vehicles, ensuring sustained revenue opportunities.

Technological Adoption: The proliferation of electric vehicles and the adoption of advanced powertrain systems require superior joint boots that can handle higher performance demands.

Economic Incentives: Cost efficiency and long-term durability offer economic benefits to vehicle manufacturers and maintenance service providers, further boosting market demand.

Economic and Policy Influences:

Government Regulations: Stringent emissions and safety standards drive the need for high-quality components, indirectly supporting demand for improved joint boot technologies.

Subsidies and Incentives: Government initiatives supporting automotive innovation and green technologies can provide financial incentives that lower production costs.

Global Trade Dynamics: International trade policies and global supply chain integration affect raw material availability and price fluctuations, influencing market stability.

Understanding these dynamics is essential for stakeholders to develop effective strategies for market expansion, cost control, and technological advancement in the competitive automotive component sector.

Regional Analysis

The global automotive constant vehicle joint boots market exhibits distinct regional trends influenced by differences in vehicle production, technological adoption, and regulatory standards:

North America:

Advanced Automotive Sector: With a robust automotive industry characterized by high vehicle production and technological innovation, North America remains a key market for advanced automotive components.

High Aftermarket Demand: The mature vehicle maintenance ecosystem and high emphasis on quality replacement parts drive significant aftermarket sales.

Regulatory Influence: Strict safety and quality regulations require the adoption of high-performance joint boots, ensuring market resilience.

Europe:

Stringent Standards: Europe’s rigorous safety and emission regulations are driving the demand for reliable and durable CV joint boots.

Strong OEM Presence: The region is home to several leading automotive manufacturers and technology innovators, promoting advanced component integration.

Sustainability Focus: Environmental awareness and sustainability initiatives are influencing product design, with increased interest in eco-friendly materials and processes.

Asia-Pacific:

Rapid Growth in Production: With booming automotive production in countries such as China, India, Japan, and South Korea, the Asia-Pacific market is witnessing accelerated demand for automotive components.

Cost-Effective Manufacturing: Emerging economies in the region are striving for efficiency and cost-effectiveness, driving competitive pricing strategies.

Technological Advancements: Increasing investments in R&D and manufacturing automation are enhancing product quality and market penetration, particularly in the aftermarket segment.

Latin America:

Emerging Market Potential: Although the automotive market is relatively smaller compared to North America or Europe, ongoing industrial modernization and expansion in vehicle production are creating opportunities.

Cost Sensitivity: Price competitiveness is critical in this region, necessitating scalable and cost-effective production methods to capture market share.

Infrastructure Development: Improvements in automotive supply chains and industrial capabilities are expected to further drive market growth.

Middle East and Africa:

Developing Automotive Markets: While still emerging, these regions are experiencing gradual growth in automotive production and aftermarket services.

Strategic Investments: Government-led initiatives and investments in infrastructure modernization are expected to spur demand for reliable automotive components.

Localized Manufacturing: Strategic partnerships with global players can help address local challenges and expand market reach.

Competitive Landscape

Leading Companies in the Global Automotive Constant Vehicle Joint Boots Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

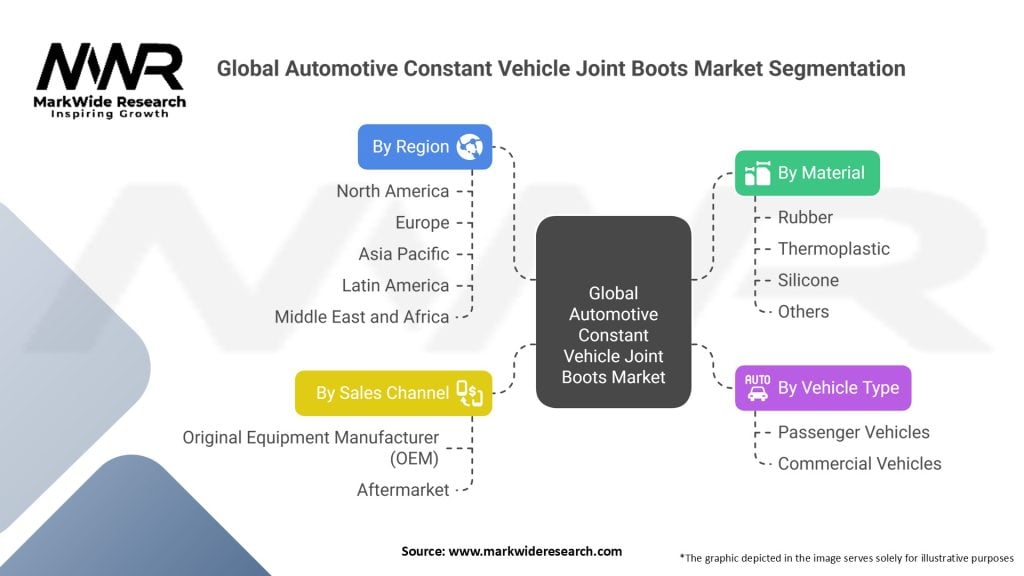

Segmentation

The global automotive constant vehicle joint boots market can be segmented based on several parameters:

By Material Type:

Standard Rubber: Traditional materials used in most applications, offering a balance between cost and performance.

High-Performance Polymers: Advanced formulations that provide enhanced durability, heat resistance, and chemical stability.

Composite Materials: Hybrid materials that combine the benefits of rubber and polymers for improved performance in critical applications.

By Application:

OEM (Original Equipment Manufacturer): Components integrated during vehicle manufacturing, where high quality and long-term performance are critical.

Aftermarket: Replacement parts for maintenance and repair of vehicles, driven by the need to replace worn or damaged joint boots over a vehicle’s lifespan.

By Vehicle Type:

Passenger Cars: High-volume segment with a focus on performance, safety, and reliability in everyday commuting vehicles.

Commercial Vehicles: Trucks, buses, and other commercial transportation vehicles where durability and performance under heavy-duty conditions are essential.

Specialty Vehicles: High-performance, luxury, or off-road vehicles that require specialized, high-end components to meet unique operating conditions.

By Distribution Channel:

Direct Sales: Sales through manufacturer-owned channels targeting OEMs and large distributors.

Authorized Distributors: Regional and global distributors who supply automotive components to various markets.

Online Retail: E-commerce and digital channels providing access to replacement parts for maintenance and repair services.

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Segmenting the market in this manner allows stakeholders to fine-tune their strategies, target specific customer segments, and optimize product offerings for various applications and regions.

Category-wise Insights

Each category within the global automotive constant vehicle joint boots market provides distinct insights into market trends and performance:

Material Type:

Standard Rubber Boots: Widely used for general applications, offering cost efficiency and reliable performance.

High-Performance Polymers: Preferred for applications requiring superior durability, especially in high-temperature or high-stress environments.

Composite Materials: Offer specialized performance benefits, making them ideal for niche applications where additional reinforcement is required.

Application:

OEM Applications: Demand for high-quality, durable components in new vehicle production drives significant growth, with stringent quality requirements ensuring long-term reliability.

Aftermarket Applications: The replacement segment is crucial, driven by vehicle aging and the continuous need for maintenance and repairs.

Vehicle Type:

Passenger Cars: Represent a large market share due to high production volumes and evolving safety standards.

Commercial Vehicles: Emphasize durability and heavy-duty performance, with a focus on reducing downtime and maintenance costs.

Specialty Vehicles: Demand bespoke solutions tailored to unique operational challenges, offering opportunities for innovation and premium pricing.

These insights highlight the importance of material innovation, performance differentiation, and targeted marketing to meet the diverse needs of the global automotive market.

Key Benefits for Industry Participants and Stakeholders

The global automotive constant vehicle joint boots market offers multiple benefits for manufacturers, distributors, and end users:

Enhanced Vehicle Safety: Reliable CV joint boots prevent contaminants from entering the joint, reducing the risk of joint failure and ensuring vehicle safety.

Increased Durability: Advanced materials and optimized designs extend the lifespan of CV joints, reducing the frequency of repairs and replacement.

Operational Efficiency: High-quality joint boots enable smoother, more efficient vehicle operation, contributing to reduced maintenance costs and improved reliability.

Aftermarket Revenue Growth: Replacement parts form a significant revenue stream in the automotive aftermarket, driven by the continuous need for maintenance and repairs.

Technological Differentiation: Investment in high-performance materials and innovative designs enables companies to differentiate their products, commanding premium pricing and strengthening brand reputation.

Sustainability and Cost Savings: Efficient production processes and long-lasting components reduce overall resource consumption and support sustainable manufacturing practices.

Market Expansion: Expanding production capacity and distribution networks in emerging markets enable global manufacturers to tap into new customer bases and increase revenue.

These benefits collectively enhance the value proposition of CV joint boots and drive competitive advantage across the automotive supply chain.

SWOT Analysis

Strengths:

High Product Quality: Established track records for durability and performance make quality CV joint boots essential components in vehicle safety.

Technological Innovation: Ongoing advancements in materials science and manufacturing processes ensure continuous improvement in product performance.

Broad Application Spectrum: CV joint boots are used in a wide range of vehicles, from passenger cars to heavy-duty commercial vehicles, ensuring diversified market demand.

Weaknesses:

High Production Costs: Advanced materials and complex manufacturing processes can drive up production expenses, affecting overall profitability.

Supply Chain Vulnerabilities: Dependence on specific raw materials and fluctuation in their prices can impact production stability and costs.

Integration Challenges: Incorporating new, innovative designs into existing production systems and maintaining consistency across large production volumes can be challenging.

Aftermarket Competition: Intense competition in the replacement parts market may lead to pricing pressures and reduced margins.

Opportunities:

Emerging Market Expansion: Rapid industrialization and growing vehicle fleets in emerging economies present significant opportunities for market growth.

Product Customization: Developing tailored solutions for niche vehicle segments (e.g., electric vehicles, luxury cars) can drive higher margins and market differentiation.

Technological Integration: Leveraging digital manufacturing and smart quality control systems can enhance product consistency and reduce production costs.

Sustainability Initiatives: Investing in eco-friendly, recyclable materials and sustainable manufacturing practices can attract environmentally conscious customers and comply with regulatory standards.

Global Partnerships: Strategic collaborations with OEMs and distributors can streamline market access and drive sales in both new production and aftermarket sectors.

Threats:

Economic Fluctuations: Global economic instability may impact vehicle production and, by extension, demand for automotive components.

Regulatory Changes: Evolving safety and environmental regulations may require constant product adaptation, leading to increased compliance costs.

Intense Competition: High competitive pressure from established players and low-cost manufacturers may erode profit margins.

Technological Disruption: Rapid changes in automotive technologies, such as shifts toward electric vehicles and alternative drivetrains, could potentially alter market dynamics and component requirements.

Market Key Trends

Several key trends are set to shape the future of the global automotive constant vehicle joint boots market:

Adoption of Advanced Materials: Innovation in synthetic polymers and composite materials is driving the development of joint boots with superior heat resistance and durability.

Integration of Smart Manufacturing: Automation, robotics, and digital quality control systems are enhancing production efficiency and ensuring consistent product quality.

Growing Aftermarket Focus: The replacement segment continues to grow as vehicles age, with increasing demand for high-quality, long-lasting replacement parts.

Emphasis on Safety and Reliability: With rising safety standards and consumer expectations for vehicle longevity, automakers are prioritizing high-performance components to reduce maintenance issues.

Electric Vehicle (EV) Adaptation: The evolution of the automotive sector, particularly the rise of electric vehicles, is prompting manufacturers to develop specialized CV joint boots that meet the unique performance requirements of EVs.

Sustainability and Green Manufacturing: Environmental considerations are driving the adoption of sustainable production practices and the use of recyclable materials, enhancing product appeal.

Global Supply Chain Optimization: Efforts to streamline supply chains and reduce raw material dependencies are influencing manufacturing strategies, ensuring a more robust and efficient production process.

Covid-19 Impact

The Covid-19 pandemic has affected the global automotive constant vehicle joint boots market in several ways:

Temporary Production Disruptions: Lockdowns and supply chain interruptions led to short-term declines in vehicle production and component demand.

Shift in Demand Patterns: Post-pandemic recovery efforts and changes in consumer behavior have impacted vehicle maintenance cycles, with increased focus on preventive maintenance and aftermarket replacements.

Accelerated Digital Transformation: The pandemic accelerated the adoption of digital technologies in manufacturing, including advanced quality control and automation, which have enhanced production efficiency.

Increased Focus on Safety: Heightened awareness of safety protocols during the pandemic has reinforced the importance of reliable automotive components, indirectly boosting demand for high-quality joint boots.

Economic Recovery Initiatives: Government stimulus measures and infrastructure investments as part of post-pandemic recovery plans are expected to drive renewed growth in the automotive and component sectors.

Key Industry Developments

Recent developments in the automotive constant vehicle joint boots market include:

Technological Innovations: Advances in material science and manufacturing technology have led to the introduction of next-generation joint boots with improved durability, enhanced UV and chemical resistance, and superior mechanical properties.

Strategic Collaborations: Partnerships between OEMs, component manufacturers, and technology providers are accelerating the development of integrated solutions that enhance vehicle safety and performance.

Product Diversification: Companies are expanding their product portfolios to include a variety of joint boots designed for specific vehicle types, driving conditions, and performance requirements.

Global Supply Chain Integration: Efforts to optimize production logistics and ensure consistent raw material supply have improved market stability and cost competitiveness.

Investment in Automation: Increased adoption of automation and robotics in manufacturing processes is reducing production costs, improving product quality, and enabling higher production volumes.

Market Consolidation: Mergers and acquisitions in the automotive components sector are streamlining product offerings and enhancing global distribution capabilities.

Analyst Suggestions

Industry analysts recommend the following strategic initiatives for stakeholders in the global automotive constant vehicle joint boots market:

Invest in Research and Development: Focus on developing innovative materials and designs that offer improved performance, such as enhanced durability for electric vehicles and heavy-duty applications.

Strengthen Supply Chain Management: Build resilient supply chain networks to mitigate the impact of raw material price fluctuations and ensure consistent production outputs.

Enhance Product Customization: Offer tailored solutions for niche market segments, including specialized designs for different vehicle types and operational conditions.

Expand Global Distribution Networks: Develop robust partnerships with distributors and OEMs in emerging markets to capture new opportunities and drive market penetration.

Embrace Digital Manufacturing: Leverage digital and automation technologies to improve production efficiency, quality control, and cost management.

Focus on Sustainability: Invest in green manufacturing practices and develop eco-friendly products to meet increasing regulatory requirements and consumer demand for sustainable components.

Engage in Collaborative Ventures: Form strategic alliances with automotive manufacturers and research institutions to co-develop next-generation joint boot technologies and drive industry innovation.

Enhance Customer Support: Provide comprehensive after-sales services, including installation support, maintenance, and training programs, to build long-term customer relationships and loyalty.

Future Outlook

The global automotive constant vehicle joint boots market is positioned for strong long-term growth, driven by a combination of technological, economic, and regulatory trends:

Market Expansion: Continued growth in the global automotive industry, particularly in emerging markets, will drive demand for both OEM and aftermarket joint boots.

Technological Advancements: Ongoing innovation in materials science and manufacturing processes will enhance product performance and enable the development of specialized joint boots tailored to evolving vehicle technologies.

Shift Toward Electric Vehicles: The rapid adoption of electric vehicles will necessitate the development of new, high-performance joint boots that meet unique operational demands, providing a significant growth opportunity.

Sustainable Practices: Increasing environmental awareness and regulatory mandates for sustainability will drive the adoption of eco-friendly production methods and sustainable product formulations.

Digital Transformation: Integration of digital manufacturing processes and real-time quality control systems will improve production efficiency, reduce costs, and strengthen competitive positioning.

Global Collaboration: Strategic partnerships and international collaborations will facilitate market penetration and help navigate complex global supply chains, ensuring robust growth despite potential geopolitical and economic uncertainties.

While challenges such as high production costs, raw material volatility, and regulatory complexities remain, the overall outlook for the market is positive. Stakeholders that invest in technology, embrace sustainable practices, and focus on customer-centric solutions will be well positioned to capitalize on emerging opportunities and drive long-term success.

Conclusion

The Global Automotive Constant Vehicle Joint Boots Market plays a critical role in ensuring the reliability, durability, and safety of modern vehicles. As an indispensable component in the assembly and maintenance of constant velocity joints, CV joint boots are essential for protecting key automotive systems from contaminants and ensuring the smooth transmission of power.

In conclusion, the global automotive constant vehicle joint boots market is a dynamic and growing industry. By understanding the market overview, key market insights, regional analysis, competitive landscape, and future outlook, businesses can make informed decisions, capitalize on market opportunities, and achieve sustainable growth in this thriving market. The continuous advancements in technology, increasing vehicle production, and rising consumer awareness about vehicle maintenance and safety are expected to drive the demand for automotive constant vehicle joint boots in the coming years. By staying abreast of market trends and leveraging the opportunities presented, businesses can position themselves for success in this evolving market.

What are automotive constant vehicle joint boots?

Automotive constant vehicle joint boots are protective coverings that encase the constant velocity joints in vehicles, preventing dirt and moisture from entering and ensuring the longevity of the joint’s performance. They are essential components in the drivetrain of vehicles, particularly in front-wheel drive and all-wheel drive systems.

Who are the key players in the Global Automotive Constant Vehicle Joint Boots Market?

Key players in the Global Automotive Constant Vehicle Joint Boots Market include companies like GKN Automotive, NTN Corporation, and SKF Group, which are known for their innovative solutions and extensive product offerings in the automotive components sector, among others.

What are the main drivers of growth in the Global Automotive Constant Vehicle Joint Boots Market?

The growth of the Global Automotive Constant Vehicle Joint Boots Market is driven by the increasing demand for vehicles, advancements in automotive technology, and the rising focus on vehicle safety and performance. Additionally, the expansion of the automotive aftermarket is contributing to the demand for high-quality joint boots.

What challenges does the Global Automotive Constant Vehicle Joint Boots Market face?

The Global Automotive Constant Vehicle Joint Boots Market faces challenges such as fluctuating raw material prices and the increasing complexity of vehicle designs. These factors can impact production costs and the availability of compatible joint boots for various vehicle models.

What opportunities exist in the Global Automotive Constant Vehicle Joint Boots Market?

Opportunities in the Global Automotive Constant Vehicle Joint Boots Market include the growing trend towards electric vehicles, which require specialized joint boots, and the potential for innovations in materials that enhance durability and performance. Additionally, expanding into emerging markets presents significant growth potential.

What trends are shaping the Global Automotive Constant Vehicle Joint Boots Market?

Trends shaping the Global Automotive Constant Vehicle Joint Boots Market include the increasing adoption of lightweight materials to improve fuel efficiency and the integration of advanced manufacturing technologies such as automation and robotics. These trends are aimed at enhancing product quality and reducing production costs.

Global Automotive Constant Vehicle Joint Boots Market

| Segmentation | Details |

|---|---|

| By Material | Rubber, Thermoplastic, Silicone, Others |

| By Vehicle Type | Passenger Vehicles, Commercial Vehicles |

| By Sales Channel | Original Equipment Manufacturer (OEM), Aftermarket |

| By Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Automotive Constant Vehicle Joint Boots Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at