Key Market Insights

-

Leading equipment providers are introducing multi-format machines capable of switching between envelope, pyramid, and stick sachet styles within minutes, boosting production flexibility.

-

Integration of vision-inspection systems ensures flawless tag placement, string attachment, and seal integrity, supporting strict food safety regulations.

-

Rising demand for organic and herbal tea varieties is prompting development of gentle dosing mechanisms to handle delicate leaf structures without damage.

-

Cloud-enabled predictive maintenance services are reducing downtime by up to 30% through real-time analytics and remote troubleshooting.

Market Drivers

Several factors are propelling the market’s growth:

-

Single-Serve Trend: Consumers’ preference for convenience and portion control is driving tea producers to shift toward individually wrapped bags, escalating equipment demand.

-

Premiumization: Growth in specialty teas—such as matcha, oolong, and functional blends—requires versatile machinery capable of handling varied leaf sizes and infusion rates.

-

Operational Efficiency: Automation reduces manual labor, increases line speeds (up to 300 bags/minute in high-end models), and maintains consistent bag weights, enhancing overall equipment effectiveness (OEE).

-

Stringent Quality Standards: Compliance with food safety and traceability requirements (e.g., HACCP, ISO 22000) necessitates machines with hygienic design and integrated inspection systems.

-

Sustainability Initiatives: Rising use of biodegradable filter fabrics and elimination of plastic components in tag assemblies align with global sustainability goals, encouraging equipment upgrades.

Market Restraints

Despite promising drivers, the market faces challenges:

-

High Capital Investment: Advanced automatic packaging machines involve substantial upfront costs—including installation, validation, and operator training—limiting adoption by smaller producers.

-

Maintenance Complexity: Sophisticated servo systems, vision cameras, and pneumatic controls require specialized technical expertise for maintenance and troubleshooting.

-

Material Compatibility: Switching between different filter-paper grades or biodegradable films may necessitate mechanical adjustments, impacting changeover times if not managed with quick-change tooling.

-

Supply Chain Disruptions: Global semiconductor shortages and logistics bottlenecks can delay equipment deliveries and spare-parts availability.

-

Energy Consumption: High-speed machines consume significant power; producers must balance throughput gains against rising energy costs and carbon footprint targets.

Market Opportunities

The market presents several growth avenues:

-

Retrofit Solutions: Offering upgrade kits—such as new dosing units or vision-inspection modules—allows existing machines to be modernized, extending service life and enhancing performance.

-

Emerging Markets: Rapid urbanization and rising disposable incomes in regions like Southeast Asia, Latin America, and Africa are driving tea consumption, creating untapped demand for automated packaging lines.

-

Customization Services: Vendors providing turnkey solutions—including packaging line design, installation, and operator training—differentiate themselves by reducing time-to-production for customers.

-

Digital Twins: Simulation-based design and virtual commissioning tools allow producers to optimize line layouts and validate changeover processes before physical installation.

-

Collaborative R&D: Partnerships between machine builders, filter-media suppliers, and automation specialists can yield next-generation equipment tailored to innovative tea blends and formats.

Market Dynamics

Key dynamics shaping the market include:

-

Technological Convergence: Integration of robotics for bag transfer, AI-driven quality inspection, and centralized control systems enhances line efficiency and reduces manual intervention.

-

Regulatory Alignment: Harmonization of food-contact material regulations (e.g., FDA, EFSA) and packaging waste directives (e.g., EU Packaging Directive) drives standardization in machine design.

-

Industry 4.0 Adoption: Manufacturers increasingly deploy IIoT platforms for real-time performance monitoring, remote access, and automated alerts, boosting overall productivity.

-

Modular Architectures: Equipment designed with plug-and-play modules allows producers to scale capacity or add new functionalities—such as carton erectors or flow wrappers—without replacing the entire line.

-

Service-Based Models: Growing preference for equipment-as-a-service (EaaS) arrangements, where uptime guarantees, consumables supply, and technical support are bundled into subscription contracts.

Regional Analysis

Adoption and growth vary by region:

-

Asia Pacific: Dominant market, led by China, India, and Japan—major tea producers—investing heavily in automation to serve both domestic and export markets.

-

Europe: High demand for premium and herbal teas in Western Europe drives installation of advanced packaging systems; Eastern Europe is emerging as low-cost production hub.

-

North America: Specialty tea brands and health-conscious consumers spur demand for diverse bag formats, boosting equipment imports and domestic machine-builder growth.

-

Latin America: Growing consumption in Brazil, Argentina, and Mexico stimulates interest in mid-tier packaging lines tailored to local tea blends.

-

Middle East & Africa: Nascent but growing market; investments in food processing infrastructure and expanding retail networks create opportunities for automated tea bag production.

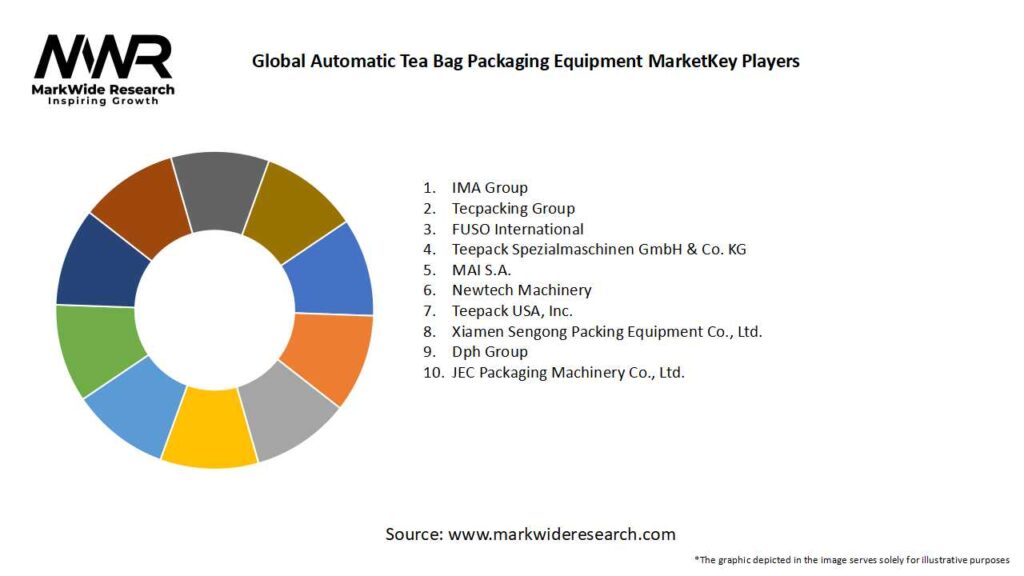

Competitive Landscape

Leading Companies in the Global Automatic Tea Bag Packaging Equipment Market:

- IMA Group

- Tecpacking Group

- FUSO International

- Teepack Spezialmaschinen GmbH & Co. KG

- MAI S.A.

- Newtech Machinery

- Teepack USA, Inc.

- Xiamen Sengong Packing Equipment Co., Ltd.

- Dph Group

- JEC Packaging Machinery Co., Ltd.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

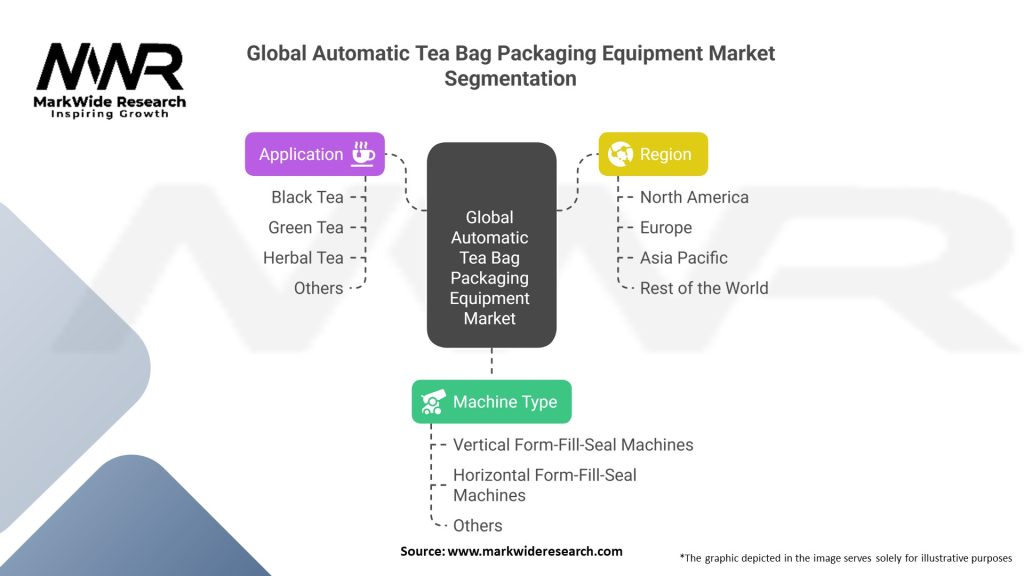

Segmentation

The market can be segmented by:

-

Machine Type: Envelope Tea Bag Machines, Pyramid / Sachet Bag Machines, Stick Sachet Machines, Flow Wrap Integrated Lines

-

Automation Level: Semi-Automatic, Fully Automatic

-

Capacity: Low (up to 50 bags/min), Medium (50–150 bags/min), High (>150 bags/min)

-

End Use: Tea Manufacturers, Contract Packagers, Private Label Brands, Foodservice & Hospitality

Category-wise Insights

-

Envelope Machines: Provide cost-effective production for traditional tea bags, widely used by large tea brands for mainstream blends.

-

Pyramid Sachet Machines: Offer premium positioning, enhanced infusion characteristics, and visual appeal, suited to specialty and herbal teas.

-

Stick Sachet Machines: Ideal for single-serve powder blends and combination beverage mixes, growing in markets with on-the-go consumption trends.

-

Flow Wrap Lines: Automate secondary packaging—cartoning, sleeving, and case packing—completing end-to-end production workflows in integrated solutions.

Key Benefits for Industry Participants and Stakeholders

-

Throughput Boost: Automated lines can produce up to 200,000 tea bags per hour, far outpacing manual or semi-automatic processes.

-

Quality Consistency: Precise dosing and sealing eliminate weight variations and bag defects, ensuring uniform brewing experiences.

-

Labor Savings: Reduced reliance on manual labor mitigates workforce challenges and lowers long-term operating costs.

-

Regulatory Compliance: Hygienic designs and traceability features simplify audits and meet stringent food-safety standards.

-

Format Flexibility: Quick-change tooling and modular upgrades allow rapid shifts between bag styles, supporting seasonal and promotional runs.

SWOT Analysis

Strengths

-

High production speeds with minimal human intervention

-

Versatile machinery accommodating multiple bag formats

-

Integrated quality-inspection and data-logging capabilities

Weaknesses

-

Significant capital and installation costs

-

Requirement for specialized maintenance expertise

-

Dependency on consistent supply of filter materials

Opportunities

-

Growing demand for premium and functional tea formats

-

Expansion into emerging markets with rising tea consumption

-

Digital service offerings and subscription-based models

Threats

-

Volatility in raw-material prices (filter paper, tag strings)

-

Supply-chain disruptions affecting critical components (sensors, drives)

-

Competition from lower-cost regional machine manufacturers

Market Key Trends

-

Eco-Friendly Packaging: Machines compatible with compostable filter materials and paper-based tags are gaining traction.

-

IoT-Enabled Lines: Remote monitoring dashboards and AI-driven analytics optimize uptime and predict component wear.

-

Rapid Format Conversion: Tool-free changeover kits reduce downtime from hours to minutes, supporting just-in-time production.

-

Collaborative Robotics: Cobots loading filter media or stacking finished output enhance operator safety and flexibility.

-

Smart Workforce Solutions: AR-guided maintenance and digital work instructions accelerate troubleshooting and training.

Covid-19 Impact

The pandemic initially disrupted supply chains and delayed new equipment installations due to factory shutdowns. However, heightened consumer focus on hygiene and single-serve products accelerated demand for fully automated, contact-minimizing packaging solutions. Remote commissioning and virtual training became standard offerings, enabling machine builders to support customers despite travel restrictions. As the global economy recovers, producers are accelerating automation investments to bolster resilience and meet evolving consumer expectations.

Key Industry Developments

-

Acquisitions & Partnerships: Major packaging groups acquiring specialized tea-bag machine builders to broaden turnkey solution portfolios.

-

Product Launches: Introduction of compact, bench-top pyramid bag machines for small-batch and artisanal tea producers.

-

Digital Service Expansion: Launch of subscription-based maintenance and spare-parts programs, leveraging predictive analytics to reduce downtime.

-

Sustainability Initiatives: Collaboration with filter-media suppliers to co-develop standardized compostable materials compatible with existing equipment lines.

Analyst Suggestions

-

Focus on Retrofit Markets: Develop easy-to-install upgrade kits for legacy machines to capture aftermarket revenue and extend machine lifecycles.

-

Strengthen Regional Support: Establish local service hubs and training centers in high-growth emerging markets to accelerate adoption and customer satisfaction.

-

Diversify Material Handling: Enhance machine adaptability to process new biodegradable and paper-free filter media without extensive retooling.

-

Leverage Data Services: Bundle IIoT-based performance monitoring and predictive maintenance into SaaS offerings to build long-term customer relationships.

Future Outlook

The Global Automatic Tea Bag Packaging Equipment Market is set for sustained growth, driven by rising global tea consumption, premiumization trends, and the quest for operational efficiency. Equipment innovations—such as modular automation, advanced vision systems, and eco-material compatibility—will shape the next wave of investments. As tea producers and packagers seek agile manufacturing models to respond to shifting consumer preferences, automatic packaging lines that combine high throughput with rapid changeover and sustainability features will command a premium. The convergence of digital services, remote support, and data-driven performance optimization promises to further enhance equipment ROI and secure market leadership for forward-thinking suppliers.

Conclusion

Automatic tea bag packaging equipment stands at the forefront of modernization in the tea industry, enabling producers to meet stringent quality, hygiene, and sustainability standards while scaling operations to satisfy global demand. By balancing speed, flexibility, and precision, these machines transform complex packaging workflows into streamlined, data-driven processes. Although challenges related to capital investment, maintenance, and material supply persist, ongoing technological advancements and service innovations are rapidly addressing these barriers. Stakeholders who embrace modular designs, digital support platforms, and eco-friendly material compatibility will be well-positioned to lead in this dynamic, high-growth market.