444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The global advanced phase change materials market has witnessed significant growth in recent years. Phase change materials (PCMs) are substances that can absorb and release large amounts of heat energy during the process of changing phases, such as from solid to liquid or liquid to gas. These materials have gained traction across various industries due to their unique thermal properties and ability to store and release energy efficiently. This market analysis provides insights into the current trends, drivers, restraints, opportunities, and future outlook of the global advanced phase change materials market.

Advanced phase change materials refer to a class of materials that undergo a phase transition, usually from solid to liquid or vice versa, while storing or releasing a significant amount of heat energy. These materials are designed to provide efficient thermal management solutions in various applications, including building and construction, energy storage, electronics, automotive, textiles, and healthcare. The use of advanced PCMs offers benefits such as enhanced energy efficiency, temperature regulation, and improved product performance.

Executive Summary

The executive summary provides a concise overview of the key highlights and findings of the global advanced phase change materials market analysis. It includes a summary of the market size, growth rate, key market insights, and major trends impacting the market. Additionally, it highlights the market drivers, restraints, and opportunities that industry participants should consider.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Building Integration Dominance: Over 45% of PCM demand stems from building‐materials applications, with PCM‐enhanced gypsum boards and concrete admixtures gaining widespread acceptance in temperate climates.

Thermal Energy Storage Synergy: Increasing deployment of renewable generation and district heating systems is driving PCMs as low‐cost, high‐density thermal storage media.

Electronics Cooling Growth: PCMs embedded in heat sinks and battery packs offer passive thermal regulation, extending device lifetimes and improving safety.

Biobased PCM Emergence: Bio‐fatty acids and eutectic blends from renewable feedstocks are capturing share from traditional paraffins, driven by sustainability mandates.

Encapsulation Technology: Micro‐ and macroencapsulation techniques using polymer shells, porous scaffolds, or metal foams are improving PCM handling, leak prevention, and heat exchange rates.

Market Drivers

Energy Efficiency Regulations: Stricter building codes (e.g., EU Nearly Zero‐Energy Buildings directive, U.S. IECC) incentivize PCM adoption to reduce HVAC loads and peak demand.

Electrification & Renewable Integration: Balancing intermittent solar and wind generation requires compact thermal storage; PCMs provide distributed energy‐storage at point of use.

Heat Management in Electronics: As power densities rise in data centers, EVs, and 5G base stations, passive PCM‐based cooling reduces reliance on active air‐ or liquid‐cooling systems.

Cold Chain Resilience: PCMs in refrigerated transport and vaccine packaging maintain strict temperature bands without external power, critical for food and pharmaceutical safety.

Sustainability Goals: Corporations and governments target carbon neutrality; PCMs contribute to lifecycle-emissions reductions in buildings and industrial processes.

Market Restraints

High Upfront Costs: PCM-enhanced materials currently carry a price premium over conventional counterparts, slowing uptake in cost-sensitive projects.

Long-Term Stability: Concerns around phase-segregation, supercooling, and shell-fracture in encapsulated PCM products can impair lifecycle performance.

Thermal Conductivity Limitations: Many PCMs have low intrinsic conductivity, necessitating additives (graphite, metal foams) that increase complexity and cost.

Standardization Gaps: Lack of unified testing methods and performance standards for PCM systems hinders project specification and comparison.

Integration Challenges: Retrofitting PCMs into existing structures or systems requires careful design to avoid moisture ingress and structural compatibility issues.

Market Opportunities

Next-Gen Composite PCMs: Development of intrinsically conductive PCM composites—e.g., carbon nanotube or graphene-enhanced—boosts heat transfer rates without heavy additives.

Additive Manufacturing: 3D printing of PCM-infused lattices enables custom shapes and localized thermal management in complex devices and architectural elements.

Smart Building Controls: Integration of PCMs with IoT sensors and building-management systems for dynamic, data-driven thermal load shifting.

Bio-Based and Recyclable Systems: Expansion of PCMs derived from agricultural byproducts and recyclable encapsulation materials aligns with circular-economy frameworks.

Emerging Market Expansion: Rapid urbanization and renewable adoption in Asia Pacific and Latin America present significant revenue streams for cost-optimized PCM solutions.

Market Dynamics

Collaborative Innovation: Joint ventures between PCM material suppliers, chemical companies, and construction firms accelerate product development and pilot deployments.

Digital Twin Simulations: Use of building-energy and CFD models to optimize PCM integration and quantify lifecycle benefits bolsters business cases.

Consolidation & Acquisitions: Established chemical manufacturers acquiring PCM technology firms to integrate latent-heat materials into broader energy-management portfolios.

Policy Incentives: Government grants and energy-efficiency subsidies for buildings and industrial process upgrades reduce net PCM system costs.

Service-Based Models: Offering PCM retrofitting as part of energy-performance contracting enables stakeholders to finance upgrades via guaranteed savings.

Regional Analysis

Asia Pacific: The fastest-growing market—led by China, India, and Southeast Asia—driven by urban construction booms, renewable project builds, and electronics manufacturing hubs.

Europe: Mature market with strong R&D clusters in Germany and Nordic countries, supportive regulatory frameworks, and high PCM per-capita adoption in buildings.

North America: Steady growth tied to green-building certifications (LEED, WELL), advanced manufacturing adoption, and defense/cold-chain applications.

Latin America: Emerging interest in passive cooling and energy-storage solutions in megacities; local pilot programs in Brazil and Mexico explore PCM-enhanced roofing and walls.

Middle East & Africa: Niche uptake in ultra-hot climates for daytime passive cooling; solar-thermal plants utilize PCMs for overnight power generation smoothing.

Competitive Landscape

Leading Companies in the Global Advanced Phase Change Materials Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

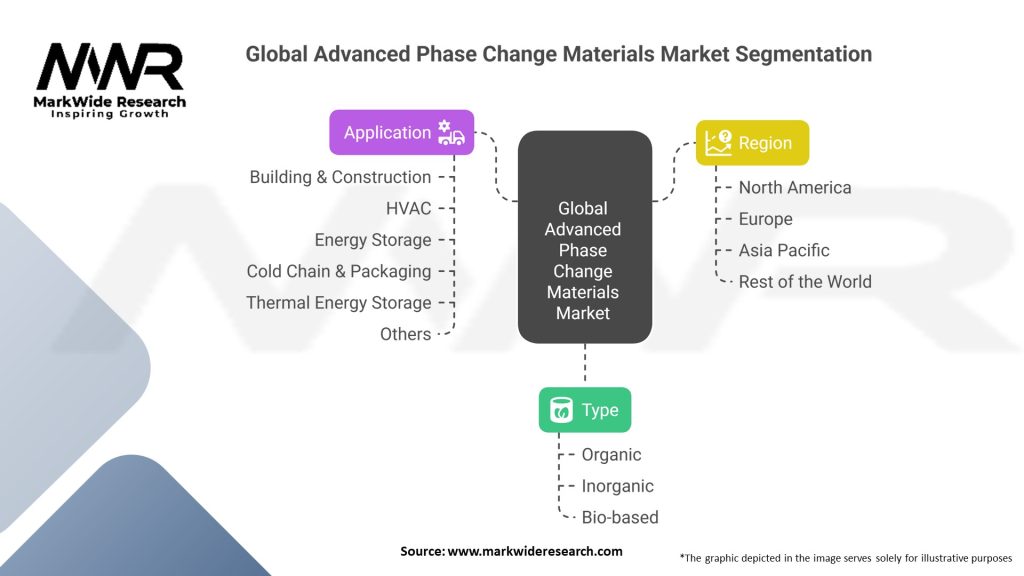

Segmentation

By Material Type: Organic (paraffins, fatty acids), Inorganic (salt hydrates), Eutectics, Bio-based PCMs

By Form Factor: Microencapsulated, Macroencapsulated, Support-matrix composites, Free-form slurries

By Application: Building Materials, Thermal Energy Storage, Electronics Cooling, Cold Chain Logistics, Textiles & Apparel, Transportation, Industrial Process Heating/Cooling

By Region: Asia Pacific, Europe, North America, Latin America, Middle East & Africa

Category-wise Insights

Microencapsulated PCMs: Preferred for incorporation into paints, gypsum boards, and textiles; offer leak prevention and fine dispersion but require shell stability.

Macroencapsulated Modules: Employed in TES tanks and HVAC systems; allow high PCM loading yet demand robust container design to accommodate volume changes.

Composite PCMs: PCM infused into porous supports (expanded graphite, metal foams) enhance conductivity; key for rapid thermal cycling applications.

Slurries & Heat-transfer Fluids: PCM micro- or nano-particles suspended in carrier fluids enable latent heat capture in hydronic systems and district energy networks.

Key Benefits for Industry Participants and Stakeholders

Energy Savings: PCMs can reduce HVAC energy consumption by up to 25% in buildings and smooth peak electric loads, lowering utility bills.

Enhanced Comfort: Passive thermal buffering maintains indoor temperatures within comfort bands, improving occupant well-being and productivity.

Process Stability: Industrial equipment and reactors benefit from isothermal conditions provided by PCM buffers, enhancing product quality and yield.

Grid Flexibility: Grid-interactive PCM systems enable demand-response participation and reduce reliance on grid infrastructure upgrades.

Sustainability Credentials: PCM integration contributes to green-building certifications, decarbonization targets, and climate-adaptation strategies.

SWOT Analysis

Strengths

Unique latent-heat storage delivers high energy density at nearly constant temperature.

Versatile across sectors—from buildings to electronics to cold chain logistics.

Weaknesses

Higher material and integration costs versus conventional insulation and storage methods.

Performance degradation risks from phase-segregation and encapsulant fatigue over many cycles.

Opportunities

Integration with renewable energy/storage hybrids—combining PCMs with batteries and thermal-electrical systems.

Growth in personalized PCM-infused consumer products (smart textiles, medical cooling wraps).

Threats

Emerging thermal-storage alternatives (thermochemical, sorption systems) in niche high-density applications.

Regulatory scrutiny on encapsulant microplastics and recycling challenges at end of life.

Market Key Trends

3D-Printed PCM Composites: Custom lattice structures printed with embedded PCM for aerospace and wearable cooling devices.

AI-Optimized Deployment: Machine-learning tools identify optimal PCM placement and sizing in building simulations for maximal benefit.

Hybrid Thermal Stores: Combining sensible-heat materials (concrete, water) with PCMs for cost-effective, layered thermal storage.

Smart Thermoregulation Textiles: PCM microcapsules embedded in fabrics for adaptive active wear, medical bandages, and bedding products.

Circular PCM Innovations: Design for disassembly and PCM recycling programs to recover paraffin and salts from end-of-life materials.

Covid-19 Impact

The Covid-19 impact analysis assesses the effects of the global pandemic on the advanced phase change materials market. It explores the disruptions caused by the pandemic, such as supply chain disruptions, production halts, and reduced demand. Additionally, it examines the market’s response to the crisis and the measures taken by industry players to mitigate the impact.

Key Industry Developments

This section provides an overview of the key developments and innovations in the advanced phase change materials industry. It covers recent product launches, partnerships, collaborations, and research and development activities. These developments shed light on the industry’s growth trajectory and the emerging opportunities for market players.

Analyst Suggestions

The analyst suggestions section offers expert recommendations and suggestions to industry participants and stakeholders. It provides insights into market entry strategies, product development, investment opportunities, and potential areas for innovation. These suggestions are based on a comprehensive analysis of the market dynamics and future outlook.

Future Outlook

The future outlook section presents a forecast of the global advanced phase change materials market. It includes market projections in terms of revenue, growth rate, and key market trends. This section helps stakeholders understand the market’s future prospects and plan their strategies accordingly.

Conclusion

In conclusion, the global advanced phase change materials market is witnessing substantial growth due to the increasing demand for energy-efficient solutions and the rising adoption of sustainable practices. The market offers numerous opportunities for industry participants, including advancements in PCM technology, emerging applications, and regional expansion. However, challenges such as high manufacturing costs and limited awareness need to be addressed. By staying informed about market dynamics, embracing innovation, and leveraging strategic partnerships, industry players can position themselves for success in the evolving advanced phase change materials market.

What is Advanced Phase Change Materials?

Advanced Phase Change Materials (PCMs) are substances that absorb and release thermal energy during the process of melting and freezing. They are used in various applications, including thermal energy storage, temperature control in buildings, and in textiles for temperature regulation.

What are the key players in the Global Advanced Phase Change Materials Market?

Key players in the Global Advanced Phase Change Materials Market include BASF, Honeywell, and Phase Change Energy Solutions, among others. These companies are involved in the development and production of innovative PCM solutions for various applications.

What are the growth factors driving the Global Advanced Phase Change Materials Market?

The growth of the Global Advanced Phase Change Materials Market is driven by increasing demand for energy-efficient solutions, advancements in building materials, and the rising need for thermal management in electronics. Additionally, the growing focus on renewable energy sources contributes to market expansion.

What challenges does the Global Advanced Phase Change Materials Market face?

The Global Advanced Phase Change Materials Market faces challenges such as high production costs and limited awareness among end-users regarding the benefits of PCMs. Additionally, the performance limitations of certain materials in extreme temperatures can hinder market growth.

What opportunities exist in the Global Advanced Phase Change Materials Market?

Opportunities in the Global Advanced Phase Change Materials Market include the development of bio-based PCMs and the integration of PCMs in smart building technologies. The increasing adoption of energy storage systems also presents significant growth potential.

What trends are shaping the Global Advanced Phase Change Materials Market?

Trends shaping the Global Advanced Phase Change Materials Market include the rising use of nanotechnology to enhance PCM performance and the growing interest in sustainable materials. Additionally, the expansion of the electric vehicle market is driving demand for advanced thermal management solutions.

Global Advanced Phase Change Materials Market

| Segmentation | Details |

|---|---|

| Type | Organic, Inorganic, Bio-based |

| Application | Building & Construction, HVAC, Energy Storage, Cold Chain & Packaging, Thermal Energy Storage, Others |

| Region | North America, Europe, Asia Pacific, Rest of the World |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Advanced Phase Change Materials Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at