Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

-

Automotive Lightweighting: Glass mats play a vital role in composite body panels, floor pans, and structural components aimed at reducing vehicle weight and improving fuel economy.

-

Wind Energy Growth: Demand for durable rotor blade composites—often manufactured with glass mats—continues to rise, especially as onshore and offshore wind installations expand.

-

Marine and Rail Applications: The corrosion-resistant and low-maintenance properties of glass mat composites make them ideal for boat hulls, decks, and railcar interiors.

-

Construction Usage: Glass mats reinforce roofing shingles, wall panels, and pipes, offering enhanced durability and resistance to moisture and pests.

-

Technological Advancements: Development of low-emission binder systems and hybrid mats combining glass with natural fibers or nanofillers is driving product differentiation.

Market Drivers

-

Lightweighting Initiatives: Stringent fuel economy and emission regulations are pushing OEMs in automotive and aerospace sectors to adopt glass mat-reinforced composites.

-

Renewable Energy Expansion: Increasing installations of wind turbines, particularly larger offshore platforms, demand high-performance glass mat composites for longer, more efficient blades.

-

Infrastructure Modernization: Upgrades in water treatment, oil & gas pipelines, and construction projects drive demand for corrosion-resistant FRP products.

-

Cost-Effectiveness: Compared to carbon fiber, glass mat reinforcement offers a lower-cost solution for medium-strength applications, expanding composite use.

-

Sustainability Trends: Interest in recyclable composites and bio-based binders is encouraging manufacturers to innovate glass mat formulations.

Market Restraints

-

Raw Material Volatility: Fluctuations in the cost of glass fiber and polymeric binders can strain margins for mat producers.

-

Competition from Alternatives: Carbon fiber mats and natural fiber reinforcements, while more expensive or lower-performance respectively, can capture niche segments.

-

Processing Challenges: Ensuring thorough resin impregnation in thick mats and eliminating air voids requires careful process control, adding complexity.

-

Recycling Limitations: End‑of‑life composite recycling remains challenging, potentially limiting mat adoption in environmentally conscious markets.

-

Health and Safety Concerns: Handling airborne glass fibers during mat cutting and lay‑up necessitates stringent worker protection measures.

Market Opportunities

-

Bio‑Based and Low‑Emission Binders: Developing eco-friendly binders derived from renewable resources can meet regulatory pressures and consumer demand for green composites.

-

Hybrid Mats: Integrating glass fibers with carbon fibers, aramids, or natural fibers can tailor mechanical properties for automotive bumpers, structural panels, and consumer goods.

-

Automated Composite Manufacturing: Mats designed for automated tape laying and fiber placement can unlock lightweight, high-volume production in aerospace and automotive sectors.

-

Emerging Markets Growth: Rapid infrastructure development in Asia-Pacific (China, India) and Latin America (Brazil, Mexico) presents new demand centers for corrosion‑resistant composites.

-

Value‑Added Services: Offering pre‑cut mats, customized packaging, or on‑site consultancy can differentiate mat suppliers and build customer loyalty.

Market Dynamics

-

Supply Side: Consolidation among glass fiber producers, improvements in mat‑making equipment (e.g., precise fiber choppers, thermostatic ovens), and digital process control are enhancing quality and scale.

-

Demand Side: End‑users are shifting toward supplier consolidation to streamline procurement and ensure consistent mat performance across production lines.

-

Economic Factors: Interest rates, GDP growth in key markets, and capital expenditure in automotive and energy infrastructure directly influence mat demand.

-

Regulatory Environment: REACH (EU chemicals regulation), IMO (marine pollution rules), and automotive crash‑safety standards drive mat composition and supplier qualifications.

Regional Analysis

-

Asia-Pacific: Largest and fastest‑growing market, driven by China’s automotive production, wind power capacity additions, and infrastructure investments in India and Southeast Asia.

-

North America: Mature market with strong demand in automotive (US Big Three), wind energy (offshore pilot projects), and construction (FRP rebar, panels).

-

Europe: Growth fueled by strict CO₂ targets for vehicles, leading wind turbine orders (offshore North Sea), and renovation of aging infrastructure.

-

Latin America: Emerging applications in water/sewage pipes, roofing, and boat building support incremental glass mat demand.

-

Middle East & Africa: Slowly expanding market, propelled by petrochemical plants’ FRP lining requirements and nascent wind energy programs.

Competitive Landscape

Leading companies in the Glass Mat Market:

- Owens Corning

- Jushi Group Co., Ltd.

- Nippon Electric Glass Co., Ltd.

- Johns Manville Corporation

- Saint-Gobain

- Chongqing Polycomp International Corporation (CPIC)

- AGY Holding Corp.

- Binani Industries Limited

- Taishan Fiberglass Inc.

- Taiwan Glass Ind. Corp.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

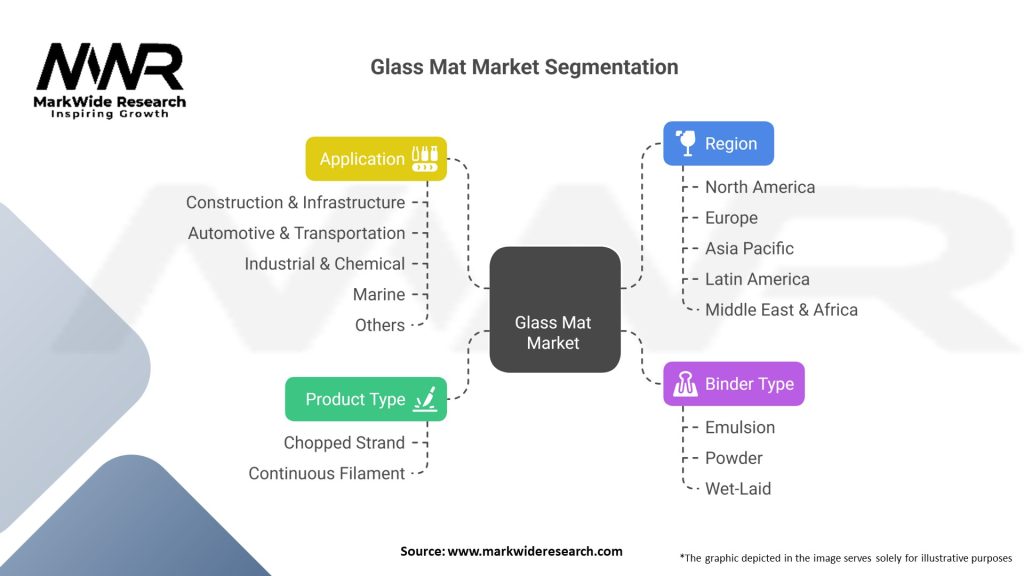

Segmentation

-

By Fiber Type: E‑glass mat (majority), C‑glass, S‑glass, specialty formulations.

-

By Binder Chemistry: Polyester‑based (most common), vinyl ester, epoxy, bio‑based.

-

By End‑Use Industry:

-

Automotive & Transportation

-

Wind Energy

-

Marine & Rail

-

Construction & Infrastructure

-

Consumer Goods (sporting equipment, RVs)

-

Industrial (pipes, tanks, panels)

-

-

By Process: Hand lay‑up, spray‑up, resin transfer molding (RTM), vacuum infusion, automated tape laying.

-

By Region: Asia‑Pacific, North America, Europe, Latin America, Middle East & Africa.

Category-wise Insights

-

Automotive Mats: Focus on lightweight structural parts, crash‑worthy bumpers, and underbody protectors.

-

Wind Energy Mats: Thick mats with tailored layup sequences for large‑span rotor blades.

-

Marine Mats: Corrosion and UV‑resistant mats for hulls, decks, and superstructures.

-

Construction Mats: Alkali‑resistant mats for cementitious composites, roofing shingles, and panels.

Key Benefits for Stakeholders

-

Enhanced Composite Performance: Uniform fiber distribution improves mechanical properties and impact resistance.

-

Cost Savings: Mats reduce waste and labor costs compared to woven fabrics in many processes.

-

Design Flexibility: Random orientation allows molding of complex geometries with consistent reinforcement.

-

Supply Chain Streamlining: Integrated fiber‑to‑mat producers ensure quality and timely deliveries.

-

Sustainability Potential: Ongoing development of bio‑binders and recyclable mats aligns with circular economy goals.

SWOT Analysis

-

Strengths: Versatile reinforcement, proven manufacturing processes, broad application base.

-

Weaknesses: Binder emissions concerns, challenges in recycling end‑of‑life composites.

-

Opportunities: Bio‑based mats, automated composite processing, emerging market penetration.

-

Threats: Raw material price volatility, competition from advanced textile reinforcements (woven, stitched fabrics), regulatory pressure on VOCs.

Market Key Trends

-

Bio‑Binder Adoption: Shift toward low‑VOC, renewable binders to meet environmental regulations.

-

Hybrid Reinforcements: Mats combining glass with carbon or basalt fibers for tailored performance.

-

Automated Manufacturing: Mats designed for rapid automated lay‑up in automotive and aerospace.

-

Recycled Glass Content: Trials with post‑consumer glass to reduce carbon footprint.

-

Digital Quality Control: Inline optical and ultrasonic inspection systems ensuring mat uniformity.

Covid-19 Impact

-

Supply Disruptions: Temporary raw material shortages and logistics delays impacted mat deliveries in 2020.

-

Demand Fluctuations: Automotive OEM shutdowns and construction project delays led to a brief dip in mat consumption.

-

Accelerated Automation: Social‑distancing norms spurred interest in automated composite processes.

-

Resilience in Wind/Marine: Projects in renewable energy and marine refit sectors showed quicker recovery, sustaining mat demand.

Key Industry Developments

-

Nichias Bio‑Binder Launch (2023): A proprietary bio‑polymer binder with >80% bio‑content.

-

Owens Corning RTM Mat Offering (2022): High‑flow mat tailored for resin transfer molding.

-

Jushi Capacity Expansion (2024): New 50,000 tpa glass fiber line dedicated to mat production.

-

Collaborations: Joint development of basalt‑glass hybrid mats for construction by multiple European producers.

-

Digital Tracking: Introduction of QR‑coded mat rolls for traceability from fiber melt to composite part.

Analyst Suggestions

-

Invest in Sustainable Binders: To preempt tightening environmental regulations and appeal to eco‑conscious OEMs.

-

Develop Hybrid Mats: Partner with carbon and basalt fiber suppliers to broaden product portfolios.

-

Focus on Automated Processing: Align mat designs with the needs of automated composite manufacturing to capture premium automotive and aerospace segments.

-

Expand in Emerging Regions: Target high‑growth markets in Southeast Asia, Latin America, and Africa through joint ventures and local production.

-

Enhance Recycling Routes: Collaborate on end‑of‑life recycling technologies for FRP to position as a full‑life‑cycle provider.

Future Outlook

The Glass Mat Market is on track for sustained growth through 2030, driven by:

-

Continued demand in automotive lightweighting and renewable energy installations.

-

Technological advancements in binder chemistry, hybrid reinforcements, and automated composite production.

-

Expansion of end‑use applications in infrastructure, consumer goods, and industrial components.

-

Increasing regulatory and customer focus on sustainability and circularity, prompting innovation in bio‑binders and recycling solutions.

Conclusion

Glass mats remain a cornerstone reinforcement in composite manufacturing, balancing cost, performance, and processing flexibility. As industries prioritize lightweighting, durability, and environmental responsibility, the Glass Mat Market will continue to evolve through binder innovation, hybrid fiber integration, and digital manufacturing advancements. Stakeholders who invest in sustainable technologies, automation alignment, and emerging market expansion will be best positioned to capture growth in this dynamic, multi‑billion‑dollar market.