444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Glass engraving machines have gained significant traction in recent years, driven by the growing demand for personalized and customized glass products across various industries. These machines provide precise and intricate engraving on glass surfaces, allowing manufacturers to add artistic designs, logos, and text to enhance the aesthetic appeal of their products. The glass engraving machines market encompasses a wide range of industries, including automotive, electronics, home decor, and gifting.

Meaning

Glass engraving machines are specialized equipment designed to etch or engrave intricate patterns, designs, or text onto glass surfaces. The process involves using cutting tools, lasers, or abrasive materials to create permanent marks on the glass. These machines enable manufacturers to produce high-quality engraved glass products, such as glassware, trophies, signage, and decorative items.

Executive Summary

The glass engraving machines market has witnessed substantial growth in recent years, fueled by the increasing demand for unique and personalized glass products. The market is driven by technological advancements in engraving machines, growing consumer preference for customized products, and the rising adoption of glass engraving in various end-use industries. However, the market also faces challenges in terms of high initial costs and the need for skilled operators. Nonetheless, the market presents lucrative opportunities for manufacturers and service providers to expand their offerings and cater to the evolving customer demands.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The market is forecast to grow at a CAGR of ~4.5% through 2030, driven by decorative, industrial marking, and personalized gift applications.

Laser engraving machines hold ~60% of revenue, while router-based and sand-blasting systems make up ~30%.

Asia-Pacific leads unit shipments due to high manufacturing and consumer goods production.

Miniaturized desktop laser engravers for small businesses and hobbyists are capturing ~20% of new sales.

Integration with CAD/CAM software and automated conveyor systems is a rising trend in high-volume settings.

Market Drivers

Personalization Trend: Demand for customized glassware, awards, and signage fuels machine adoption in SMEs.

Industrial Traceability: Engraved QR codes and serial numbers on glass components support quality control.

Technological Advances: Fiber and UV lasers enable high-precision, minimal thermal damage engraving.

Cost Declines: Falling laser-source prices and bundled software reduce entry barriers.

Design Flexibility: Ability to produce complex patterns, gradients, and multi-layer effects on glass surfaces.

Market Restraints

Material Fragility: Glass cracking and chipping risks require precise machine calibration and operator skill.

Dust and Debris: Engraving processes generate particulates that necessitate fume extraction and maintenance.

High Initial Investment: Industrial-grade laser systems cost upwards of $30,000, limiting purchase by micro-enterprises.

Safety Regulations: Laser machine operation demands compliance with eye-protection and laser-safety standards.

Competition from Coatings: Screen-printing and ceramic decals can offer lower-cost decorative alternatives.

Market Opportunities

Hybrid UV-CO₂ Systems: Multi-wavelength machines capable of engraving various glass types and coatings.

Automation Integration: Robotic loading/unloading cells for continuous, high-throughput engraving lines.

Software Ecosystems: Cloud-based design libraries and remote job management for distributed factories.

Eco-Friendly Consumables: Development of biodegradable masking films and low-emission exhaust filters.

Maker Community Engagement: Entry-level packages and educational partnerships to foster new user adoption.

Market Dynamics

The glass engraving machines market is driven by various factors, including technological advancements, changing consumer preferences, and the increasing adoption of glass engraving in multiple industries. The market is highly competitive, with manufacturers striving to offer innovative solutions to gain a competitive edge. Additionally, the market dynamics are influenced by factors such as government regulations, economic conditions, and industry collaborations.

Regional Analysis

Competitive Landscape

Leading Companies in the Glass Engraving Machines Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

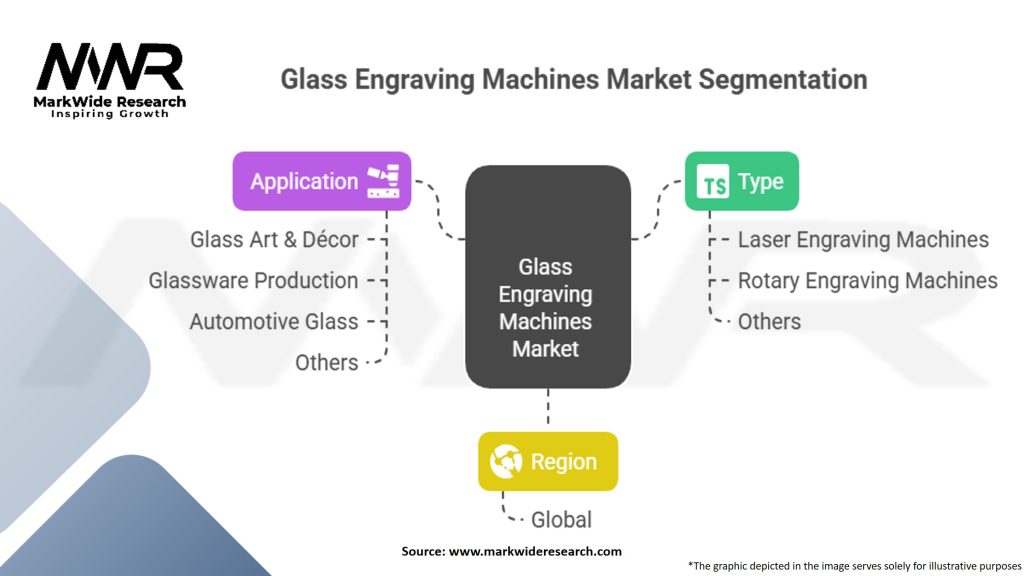

Segmentation

The glass engraving machines market can be segmented based on machine type, end-use industry, and geography.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The glass engraving machines market witnessed a temporary slowdown during the Covid-19 pandemic due to disruptions in global supply chains and reduced consumer spending. However, the market quickly recovered as the demand for personalized and customized glass products surged during the pandemic, driven by the shift towards e-commerce and the increased importance of unique gifting options.

Key Industry Developments

Analyst Suggestions

Future Outlook

The glass engraving machines market is expected to witness steady growth in the coming years, driven by the increasing demand for customized glass products and advancements in engraving technologies. Market players are anticipated to focus on innovation and strategic partnerships to gain a competitive edge. Additionally, the integration of automation, artificial intelligence, and eco-friendly engraving techniques will play a significant role in shaping the future of the market.

Conclusion

The glass engraving machines market offers lucrative opportunities for manufacturers and service providers in various industries. The demand for personalized and customized glass products, along with technological advancements, is driving market growth.

Despite challenges such as high initial costs and the need for skilled operators, the market is expected to expand with the exploration of untapped markets and the integration of automation. By staying abreast of market trends and focusing on innovation, industry participants can capitalize on the growing demand for engraved glass products and carve a successful path in the glass engraving machines market.

What is Glass Engraving Machines?

Glass engraving machines are specialized tools used to etch designs, patterns, or text onto glass surfaces. They utilize various techniques such as sandblasting, laser engraving, or rotary engraving to achieve precise and intricate results.

What are the key players in the Glass Engraving Machines Market?

Key players in the Glass Engraving Machines Market include companies like Gravotech, Trotec Laser, and Epilog Laser, which are known for their innovative engraving solutions. These companies offer a range of machines suitable for different applications, including industrial and artistic uses, among others.

What are the growth factors driving the Glass Engraving Machines Market?

The growth of the Glass Engraving Machines Market is driven by increasing demand for personalized glass products and advancements in engraving technology. Additionally, the rise in decorative glass applications in architecture and interior design contributes to market expansion.

What challenges does the Glass Engraving Machines Market face?

The Glass Engraving Machines Market faces challenges such as high initial investment costs and the need for skilled operators. Moreover, competition from alternative engraving methods can also hinder market growth.

What opportunities exist in the Glass Engraving Machines Market?

Opportunities in the Glass Engraving Machines Market include the growing trend of customization in consumer products and the expansion of e-commerce platforms for personalized gifts. Additionally, advancements in automation and smart technology present new avenues for innovation.

What trends are shaping the Glass Engraving Machines Market?

Trends in the Glass Engraving Machines Market include the increasing adoption of laser engraving technology due to its precision and efficiency. Furthermore, there is a rising interest in eco-friendly engraving practices and materials, reflecting broader sustainability goals in manufacturing.

Glass Engraving Machines Market

| Segmentation Details | Information |

|---|---|

| Type | Laser Engraving Machines, Rotary Engraving Machines, Others |

| Application | Glass Art & Décor, Glassware Production, Automotive Glass, Others |

| Region | Global |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Glass Engraving Machines Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at