444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Germany data center cooling market represents a critical segment of the nation’s rapidly expanding digital infrastructure ecosystem. As one of Europe’s leading technology hubs, Germany has witnessed unprecedented growth in data center construction and modernization, driving substantial demand for advanced cooling solutions. The market encompasses various cooling technologies including air-based systems, liquid cooling solutions, and innovative hybrid approaches designed to maintain optimal operating temperatures for mission-critical IT equipment.

Market dynamics indicate that Germany’s data center cooling sector is experiencing robust expansion, with growth rates consistently outpacing traditional infrastructure markets. The increasing digitalization of German businesses, coupled with stringent energy efficiency regulations and sustainability mandates, has created a compelling environment for cooling technology innovation. Energy efficiency improvements of up to 40% are being achieved through next-generation cooling systems, making them attractive investments for data center operators seeking to reduce operational costs while meeting environmental compliance requirements.

Regional concentration shows that major metropolitan areas including Frankfurt, Munich, Berlin, and Hamburg account for approximately 75% of Germany’s data center cooling market activity. These cities serve as primary hubs for cloud service providers, enterprise data centers, and colocation facilities, creating concentrated demand for sophisticated cooling infrastructure. The market’s growth trajectory reflects Germany’s position as a digital gateway between Western and Eastern Europe, with increasing data traffic and storage requirements driving continuous investment in cooling technologies.

The Germany data center cooling market refers to the comprehensive ecosystem of technologies, systems, and services designed to maintain optimal thermal conditions within data center facilities across the German territory. This market encompasses the design, manufacturing, installation, and maintenance of cooling equipment specifically engineered to remove heat generated by IT infrastructure components including servers, storage systems, networking equipment, and power distribution units.

Cooling solutions in this context include traditional computer room air conditioning (CRAC) units, computer room air handlers (CRAH), precision cooling systems, liquid cooling technologies, immersion cooling solutions, and advanced containment systems. The market also covers supporting infrastructure such as chillers, cooling towers, heat exchangers, and sophisticated monitoring and control systems that ensure consistent temperature and humidity levels throughout data center environments.

Market scope extends beyond hardware to include comprehensive services such as thermal management consulting, energy efficiency optimization, predictive maintenance, and system integration services. This holistic approach reflects the critical importance of cooling systems in maintaining data center reliability, performance, and energy efficiency while supporting Germany’s digital transformation initiatives and compliance with increasingly stringent environmental regulations.

Germany’s data center cooling market stands at the forefront of European digital infrastructure development, driven by accelerating cloud adoption, edge computing deployment, and artificial intelligence workload expansion. The market demonstrates exceptional resilience and growth potential, supported by Germany’s robust economy, advanced manufacturing capabilities, and commitment to sustainable technology solutions.

Key growth drivers include the rapid expansion of hyperscale data centers, increasing power densities requiring advanced cooling solutions, and regulatory pressures promoting energy-efficient operations. German data centers are achieving power usage effectiveness (PUE) improvements of approximately 15-20% through implementation of modern cooling technologies, making efficiency optimization a primary market catalyst.

Technology trends show significant momentum toward liquid cooling solutions, with adoption rates increasing by 35% annually among high-performance computing applications. The market is also witnessing growing interest in free cooling technologies that leverage Germany’s favorable climate conditions to reduce mechanical cooling requirements. Sustainability initiatives are reshaping market dynamics, with data center operators increasingly prioritizing cooling solutions that support carbon neutrality goals and circular economy principles.

Competitive landscape features a mix of global technology leaders and specialized German engineering companies, creating a dynamic environment for innovation and market development. The market’s future outlook remains highly positive, supported by continued digitalization trends, 5G network deployment, and Germany’s strategic position as a European data hub.

Strategic market insights reveal several critical factors shaping Germany’s data center cooling landscape:

Market maturity indicators suggest that Germany’s data center cooling sector has evolved beyond basic infrastructure provision to encompass comprehensive thermal management solutions. This evolution reflects increasing sophistication in cooling requirements and growing emphasis on total cost of ownership optimization rather than initial capital expenditure minimization.

Digital transformation acceleration serves as the primary catalyst driving Germany’s data center cooling market expansion. The country’s comprehensive digitalization strategy, encompassing Industry 4.0 initiatives, smart city development, and digital government services, has created unprecedented demand for data processing and storage capabilities. This digital infrastructure expansion directly translates to increased cooling requirements as data centers scale to accommodate growing computational workloads.

Cloud computing adoption continues to surge across German enterprises, with migration rates increasing substantially as organizations seek operational flexibility and cost optimization. Major international cloud service providers are establishing significant infrastructure presence in Germany to serve both domestic and European markets, creating concentrated demand for sophisticated cooling solutions capable of supporting hyperscale operations.

Regulatory compliance requirements are compelling data center operators to invest in energy-efficient cooling technologies. Germany’s commitment to carbon neutrality by 2045 has resulted in stringent energy performance standards for data centers, with cooling systems representing approximately 30-40% of total facility energy consumption. These regulations create strong incentives for adopting advanced cooling technologies that deliver superior efficiency performance.

Artificial intelligence and machine learning workload expansion is driving demand for high-performance computing infrastructure that generates substantial heat loads. These applications require specialized cooling solutions capable of managing increased power densities while maintaining optimal operating conditions for sensitive AI accelerators and specialized processors.

Edge computing deployment is creating new market opportunities as distributed computing architectures require cooling solutions for smaller, geographically dispersed facilities. This trend is particularly relevant in Germany’s industrial regions where edge computing supports manufacturing automation and real-time data processing applications.

High capital investment requirements represent a significant barrier to market entry and expansion, particularly for advanced cooling technologies such as liquid cooling and immersion systems. The substantial upfront costs associated with implementing sophisticated cooling infrastructure can deter smaller data center operators and limit market penetration of innovative solutions.

Technical complexity associated with modern cooling systems creates challenges for implementation and ongoing maintenance. Advanced liquid cooling solutions, while offering superior efficiency, require specialized expertise for design, installation, and operation that may not be readily available in all market segments or geographic regions.

Regulatory compliance complexity can create implementation delays and increased costs as data center operators navigate evolving environmental regulations, building codes, and energy efficiency standards. The need to ensure compliance with multiple regulatory frameworks can slow decision-making processes and complicate cooling system selection.

Supply chain constraints have impacted cooling equipment availability and pricing, particularly for specialized components and advanced technologies. Global semiconductor shortages and manufacturing disruptions have created delivery delays and cost pressures that affect market growth dynamics.

Skills shortage in specialized cooling system design and maintenance creates operational challenges for data center operators. The rapid evolution of cooling technologies requires continuous workforce development and training, which can strain organizational resources and limit adoption of advanced solutions.

Legacy infrastructure limitations in existing data centers can constrain cooling system upgrades and modernization efforts. Retrofitting older facilities with advanced cooling technologies often requires significant structural modifications and system integration work that increases project complexity and costs.

Sustainability-driven innovation presents substantial opportunities for cooling technology providers to develop and commercialize environmentally friendly solutions. Germany’s commitment to carbon neutrality and circular economy principles creates strong market demand for cooling systems that minimize environmental impact while delivering superior performance.

Liquid cooling technology expansion offers significant growth potential as data centers transition to higher power densities and specialized computing applications. The increasing adoption of AI, machine learning, and high-performance computing workloads creates opportunities for liquid cooling solution providers to capture market share from traditional air cooling systems.

Free cooling optimization represents an attractive opportunity given Germany’s favorable climate conditions. Cooling system providers can develop solutions that maximize utilization of ambient air cooling during cooler months, reducing mechanical cooling requirements and energy consumption.

Edge computing infrastructure development creates opportunities for compact, efficient cooling solutions designed for distributed deployment. The growing need for low-latency computing capabilities in industrial and urban environments drives demand for specialized cooling systems optimized for smaller facilities.

Retrofit and modernization of existing data centers presents substantial market opportunities as operators seek to improve energy efficiency and comply with evolving regulations. Cooling system providers can develop solutions specifically designed for upgrading legacy infrastructure while minimizing disruption to ongoing operations.

Service-based business models offer opportunities for cooling system providers to develop recurring revenue streams through maintenance, monitoring, and optimization services. Cooling-as-a-Service models can reduce customer capital expenditure requirements while ensuring optimal system performance throughout the equipment lifecycle.

Market dynamics in Germany’s data center cooling sector reflect the complex interplay between technological advancement, regulatory requirements, and evolving customer demands. The market demonstrates strong momentum driven by digital transformation initiatives and increasing recognition of cooling systems’ critical role in data center efficiency and reliability.

Technology evolution is accelerating as cooling system providers respond to changing requirements for higher efficiency, greater reliability, and improved sustainability performance. Innovation cycles are shortening as market participants race to develop solutions that address emerging challenges such as increased power densities and environmental compliance requirements.

Customer behavior patterns show increasing sophistication in cooling system evaluation and selection processes. Data center operators are adopting total cost of ownership approaches that consider energy efficiency, maintenance requirements, and environmental impact alongside initial capital costs. This shift is driving demand for premium cooling solutions that deliver superior long-term value.

Competitive intensity is increasing as both established players and new entrants compete for market share in Germany’s expanding data center cooling market. Competition is driving innovation and forcing market participants to differentiate through technology leadership, service excellence, and customer relationship management.

Supply chain evolution is reshaping market dynamics as cooling system providers adapt to changing component availability, cost structures, and delivery requirements. Market participants are developing more resilient supply chains and exploring local sourcing opportunities to reduce dependency on global supply networks.

Partnership strategies are becoming increasingly important as cooling system providers collaborate with data center developers, system integrators, and technology vendors to deliver comprehensive solutions. These partnerships enable market participants to leverage complementary capabilities and access new customer segments.

Comprehensive market analysis for Germany’s data center cooling market employs a multi-faceted research approach combining primary and secondary research methodologies. The research framework encompasses quantitative data collection, qualitative insights gathering, and expert opinion synthesis to provide accurate and actionable market intelligence.

Primary research activities include structured interviews with key market participants including cooling system manufacturers, data center operators, system integrators, and industry consultants. These interviews provide firsthand insights into market trends, competitive dynamics, technology developments, and customer requirements that shape market evolution.

Secondary research sources encompass industry reports, government publications, regulatory documents, company financial statements, and technical literature. This comprehensive information base ensures research findings reflect current market conditions and emerging trends that influence market development.

Data validation processes involve cross-referencing information from multiple sources and conducting follow-up interviews to verify key findings. This rigorous validation approach ensures research accuracy and reliability while identifying potential data inconsistencies or market perception gaps.

Market modeling techniques utilize statistical analysis and forecasting methodologies to project market trends and quantify growth opportunities. These models incorporate historical data, current market conditions, and forward-looking indicators to generate reliable market projections.

Expert panel consultations provide additional validation and insight into market dynamics, technology trends, and competitive developments. Industry experts contribute specialized knowledge that enhances research depth and accuracy while providing context for market findings.

Frankfurt region dominates Germany’s data center cooling market, accounting for approximately 35% of national market activity. As Europe’s financial capital and a major internet exchange hub, Frankfurt hosts numerous hyperscale data centers and enterprise facilities requiring sophisticated cooling infrastructure. The region’s strategic location and excellent connectivity make it attractive for international cloud service providers and financial services organizations.

Munich metropolitan area represents the second-largest regional market, capturing roughly 20% of Germany’s data center cooling demand. The region’s strong technology sector, including automotive, aerospace, and manufacturing industries, drives substantial demand for data processing capabilities and associated cooling infrastructure. Munich’s position as a technology innovation center supports adoption of advanced cooling solutions.

Berlin region accounts for approximately 15% of the national market, driven by government digitalization initiatives, startup ecosystem growth, and increasing enterprise cloud adoption. The capital’s role as a political and administrative center creates demand for secure, reliable data center infrastructure with appropriate cooling systems.

Hamburg area captures about 12% of market share, supported by the city’s importance as a logistics and media hub. The region’s strategic location for serving Northern European markets makes it attractive for data center development and cooling system deployment.

Rhine-Ruhr metropolitan region represents approximately 10% of the market, driven by industrial digitalization and the area’s dense population concentration. The region’s manufacturing heritage creates opportunities for edge computing deployment and associated cooling requirements.

Other regions collectively account for the remaining 8% of market activity, with growing interest in distributed data center deployment and edge computing infrastructure driving cooling demand in smaller cities and industrial areas throughout Germany.

Market leadership in Germany’s data center cooling sector features a diverse mix of global technology companies and specialized European providers. The competitive environment is characterized by ongoing innovation, strategic partnerships, and increasing focus on sustainability and energy efficiency.

Competitive strategies focus on technology differentiation, energy efficiency leadership, and comprehensive service offerings. Market participants are investing heavily in research and development to create innovative cooling solutions that address evolving customer requirements and regulatory mandates.

Market consolidation trends show increasing merger and acquisition activity as companies seek to expand capabilities, geographic reach, and customer base. Strategic acquisitions enable market participants to access new technologies and strengthen competitive positioning.

By Technology:

By Application:

By End-User Industry:

By Cooling Capacity:

Air-based cooling systems continue to dominate the German market, representing the majority of installed cooling capacity. These systems benefit from established infrastructure, proven reliability, and lower initial costs. However, efficiency limitations and increasing power densities are driving gradual transition toward more advanced cooling technologies.

Liquid cooling solutions are experiencing rapid growth, with adoption rates increasing by approximately 25% annually in high-performance computing applications. Direct-to-chip cooling and immersion cooling technologies are gaining traction as data centers seek to manage higher power densities while improving energy efficiency.

Free cooling technologies offer significant opportunities in Germany’s temperate climate, with potential energy savings of 20-30% during cooler months. Economizer systems and ambient air cooling solutions are increasingly integrated into cooling system designs to maximize efficiency and reduce operational costs.

Hyperscale applications drive demand for large-scale, highly efficient cooling systems capable of supporting massive computational workloads. These facilities prioritize energy efficiency, scalability, and automation capabilities in cooling system selection and implementation.

Edge computing requirements are creating demand for compact, efficient cooling solutions optimized for distributed deployment. These applications require cooling systems that can operate reliably in diverse environments while minimizing maintenance requirements and energy consumption.

Retrofit applications present unique challenges requiring cooling solutions that can integrate with existing infrastructure while delivering improved performance. Modular cooling systems and phased implementation approaches are gaining popularity for modernization projects.

Data center operators benefit from advanced cooling technologies through reduced energy costs, improved reliability, and enhanced operational efficiency. Modern cooling systems can deliver energy savings of 15-25% compared to legacy solutions while providing better temperature control and system monitoring capabilities.

Technology providers gain access to a growing market with strong demand for innovative cooling solutions. The market’s emphasis on energy efficiency and sustainability creates opportunities for companies developing advanced cooling technologies to capture premium pricing and establish competitive differentiation.

System integrators benefit from increasing complexity in cooling system design and implementation, creating opportunities for specialized services and long-term customer relationships. The need for comprehensive thermal management solutions supports service-based revenue models and recurring income streams.

End-user organizations achieve improved IT infrastructure reliability, reduced operational costs, and better environmental compliance through advanced cooling systems. These benefits support business continuity objectives while contributing to corporate sustainability goals.

Government stakeholders benefit from improved energy efficiency and reduced environmental impact of data center operations. Advanced cooling technologies support national energy efficiency goals and carbon reduction commitments while enabling digital transformation initiatives.

Environmental stakeholders gain from reduced energy consumption and carbon emissions associated with data center cooling operations. Advanced cooling technologies contribute to circular economy objectives and sustainable technology development.

Strengths:

Weaknesses:

Opportunities:

Threats:

Liquid cooling adoption acceleration represents the most significant trend transforming Germany’s data center cooling market. As computing workloads become more intensive and power densities increase, traditional air cooling systems are reaching their efficiency limits. Liquid cooling technologies, including direct-to-chip and immersion cooling, are gaining traction with adoption rates growing by 30% annually in high-performance computing applications.

Artificial intelligence integration is revolutionizing cooling system management and optimization. AI-powered cooling management systems can predict thermal loads, optimize cooling distribution, and automatically adjust system parameters to maintain optimal conditions while minimizing energy consumption. These intelligent systems are delivering efficiency improvements of 10-15% compared to traditional control systems.

Sustainability-driven innovation is reshaping product development and market positioning as data center operators prioritize environmental responsibility. Cooling system providers are developing solutions that utilize renewable energy, minimize water consumption, and support circular economy principles. This trend is particularly strong in Germany given the country’s commitment to carbon neutrality.

Modular and prefabricated solutions are gaining popularity as data center operators seek faster deployment and greater flexibility. Modular cooling systems enable rapid scaling and reduce on-site construction requirements, making them attractive for both new construction and retrofit applications.

Edge computing expansion is creating demand for distributed cooling solutions optimized for smaller facilities and diverse operating environments. These applications require cooling systems that can operate autonomously with minimal maintenance while delivering reliable performance.

Free cooling optimization is becoming increasingly sophisticated as cooling system providers develop solutions that maximize utilization of Germany’s favorable climate conditions. Advanced economizer systems and hybrid cooling approaches can reduce mechanical cooling requirements by 25-35% during cooler months.

Technology partnerships are accelerating innovation in cooling system development as companies collaborate to create comprehensive solutions. Recent partnerships between cooling system manufacturers and semiconductor companies are driving development of specialized cooling solutions for AI and machine learning applications.

Regulatory updates continue to shape market dynamics as German authorities refine energy efficiency standards and environmental requirements for data centers. New regulations requiring detailed energy reporting and efficiency targets are driving adoption of advanced cooling technologies.

Investment announcements from major cloud service providers indicate continued expansion of hyperscale data center capacity in Germany. These investments create substantial demand for large-scale cooling infrastructure and drive market growth.

Research and development initiatives are advancing cooling technology capabilities, with particular focus on liquid cooling systems, AI-powered management, and sustainable cooling solutions. German research institutions and companies are collaborating on next-generation cooling technologies.

Acquisition activity in the cooling system market reflects consolidation trends as companies seek to expand capabilities and market reach. Recent acquisitions have focused on liquid cooling specialists and service providers.

Sustainability certifications are becoming increasingly important as data center operators seek to demonstrate environmental responsibility. Cooling system providers are developing solutions that support green building certifications and sustainability reporting requirements.

MarkWide Research recommends that cooling system providers prioritize development of liquid cooling solutions to capitalize on growing demand from high-performance computing applications. The transition from air-based to liquid cooling systems represents a significant market opportunity that requires early positioning and technology leadership.

Investment in AI and automation capabilities should be a priority for cooling system manufacturers seeking competitive differentiation. Intelligent cooling management systems that optimize performance and reduce energy consumption will become increasingly important as data center operators focus on operational efficiency.

Partnership strategies with data center developers, system integrators, and technology vendors can accelerate market penetration and create comprehensive solution offerings. Collaborative approaches enable cooling system providers to access new customer segments and deliver integrated solutions.

Service model development offers opportunities to create recurring revenue streams and strengthen customer relationships. Cooling-as-a-Service models, predictive maintenance programs, and optimization services can differentiate providers in competitive markets.

Sustainability focus should be integrated into product development and marketing strategies as environmental considerations become increasingly important in customer decision-making. Cooling solutions that support carbon neutrality goals and circular economy principles will gain competitive advantage.

Regional expansion beyond major metropolitan areas can capture emerging opportunities in edge computing and distributed data center deployment. Smaller cities and industrial regions represent untapped market potential for specialized cooling solutions.

Market growth trajectory for Germany’s data center cooling sector remains highly positive, supported by continued digital transformation, cloud computing adoption, and artificial intelligence deployment. MWR analysis indicates that the market will experience sustained expansion driven by increasing data processing requirements and evolving cooling technology capabilities.

Technology evolution will accelerate as cooling system providers respond to changing requirements for higher efficiency, greater reliability, and improved sustainability performance. Liquid cooling technologies are expected to capture increasing market share, with adoption rates potentially reaching 45% of new installations within the next five years.

Regulatory environment will continue to influence market development as German authorities implement stricter energy efficiency standards and environmental requirements. These regulations will drive demand for advanced cooling technologies while creating barriers for less efficient solutions.

Investment levels in data center infrastructure are expected to remain robust, supported by cloud computing growth, edge computing deployment, and digital transformation initiatives. This investment activity will sustain demand for cooling systems and drive market expansion.

Innovation cycles will shorten as market participants compete to develop solutions that address emerging challenges such as increased power densities, sustainability requirements, and operational automation. Research and development investment will intensify as companies seek competitive differentiation.

Market consolidation may accelerate as companies seek to achieve scale advantages and expand capabilities through mergers and acquisitions. This consolidation could create larger, more capable market participants while potentially reducing competitive intensity in some segments.

Germany’s data center cooling market represents a dynamic and rapidly evolving sector that plays a critical role in supporting the country’s digital infrastructure development. The market demonstrates strong growth potential driven by digital transformation initiatives, cloud computing adoption, and increasing recognition of cooling systems’ importance in data center efficiency and sustainability.

Technology innovation continues to reshape market dynamics as cooling system providers develop advanced solutions that address evolving customer requirements and regulatory mandates. The transition toward liquid cooling technologies, AI-powered management systems, and sustainable cooling solutions reflects the market’s commitment to performance improvement and environmental responsibility.

Competitive landscape features a diverse mix of global technology leaders and specialized providers, creating a dynamic environment for innovation and market development. Success in this market requires technology leadership, comprehensive service capabilities, and strong customer relationships.

Future prospects remain highly favorable as Germany’s position as a European digital hub continues to attract data center investment and drive cooling system demand. The market’s evolution toward more sophisticated, efficient, and sustainable cooling solutions positions it for continued growth and technological advancement in the years ahead.

What is Data Center Cooling?

Data Center Cooling refers to the methods and technologies used to maintain optimal temperature and humidity levels in data centers, ensuring the efficient operation of servers and IT equipment. Effective cooling is crucial for preventing overheating and ensuring reliability in data processing environments.

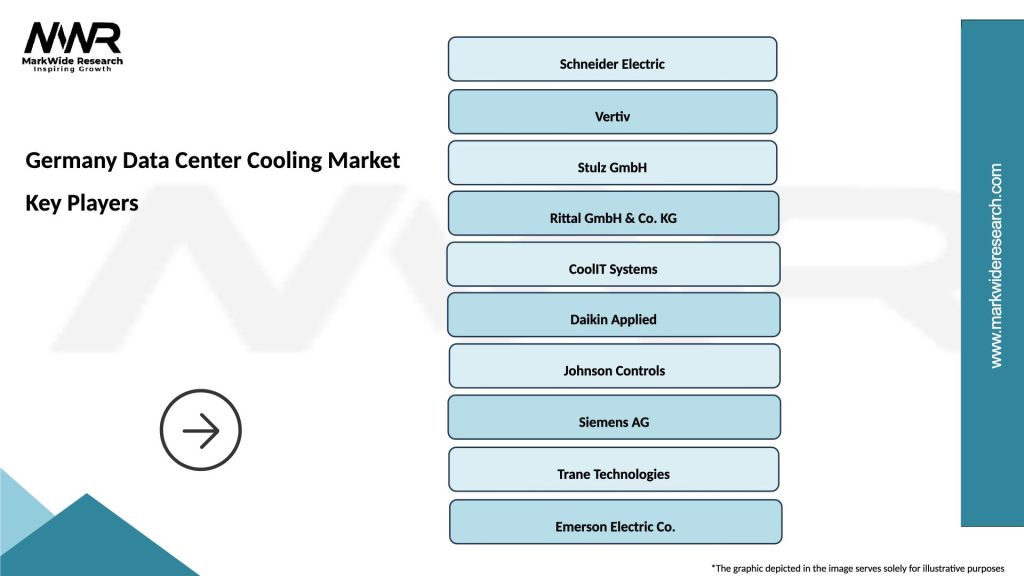

What are the key players in the Germany Data Center Cooling Market?

Key players in the Germany Data Center Cooling Market include companies like Schneider Electric, Vertiv, and Rittal, which provide innovative cooling solutions and technologies. These companies focus on energy efficiency and advanced cooling systems to meet the growing demands of data centers, among others.

What are the main drivers of the Germany Data Center Cooling Market?

The main drivers of the Germany Data Center Cooling Market include the increasing demand for data storage and processing, the rise of cloud computing, and the need for energy-efficient cooling solutions. Additionally, the growth of big data analytics and IoT applications further fuels the market.

What challenges does the Germany Data Center Cooling Market face?

The Germany Data Center Cooling Market faces challenges such as high energy consumption and operational costs associated with cooling systems. Additionally, the need for compliance with environmental regulations and the integration of sustainable practices can pose significant hurdles.

What opportunities exist in the Germany Data Center Cooling Market?

Opportunities in the Germany Data Center Cooling Market include the development of advanced cooling technologies, such as liquid cooling and free cooling systems. Furthermore, the increasing focus on sustainability and energy efficiency presents avenues for innovation and growth.

What trends are shaping the Germany Data Center Cooling Market?

Trends shaping the Germany Data Center Cooling Market include the adoption of modular cooling solutions and the integration of AI for predictive maintenance. Additionally, there is a growing emphasis on hybrid cooling systems that combine traditional and innovative methods to enhance efficiency.

Germany Data Center Cooling Market

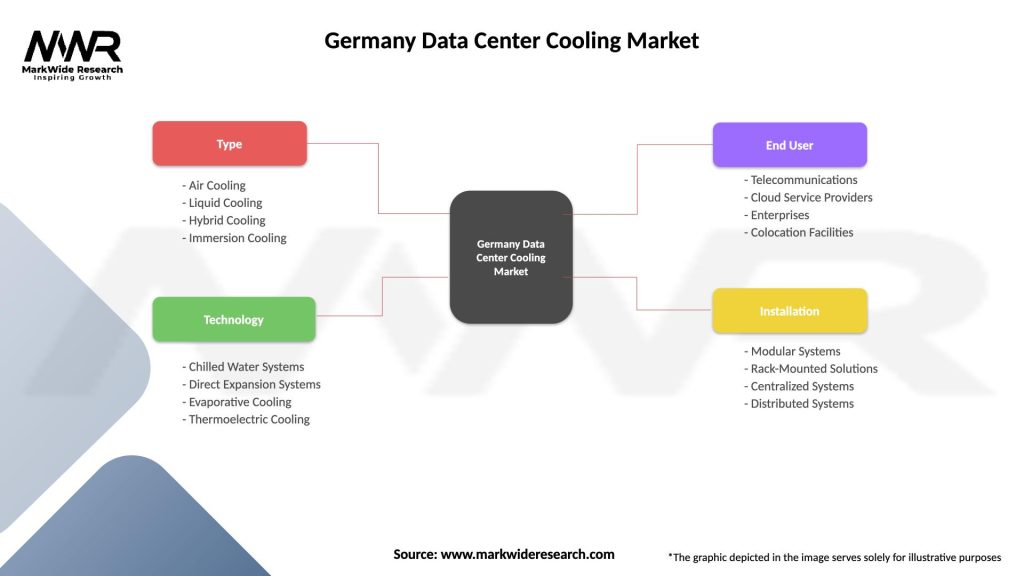

| Segmentation Details | Description |

|---|---|

| Type | Air Cooling, Liquid Cooling, Hybrid Cooling, Immersion Cooling |

| Technology | Chilled Water Systems, Direct Expansion Systems, Evaporative Cooling, Thermoelectric Cooling |

| End User | Telecommunications, Cloud Service Providers, Enterprises, Colocation Facilities |

| Installation | Modular Systems, Rack-Mounted Solutions, Centralized Systems, Distributed Systems |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Germany Data Center Cooling Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at