444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The GCC (Gulf Cooperation Council) region has witnessed significant growth in the prefabricated building and structural steel market in recent years. Prefabricated buildings, also known as modular construction, involve the assembly of various components off-site and then transporting them to the desired location for final installation. This method offers several advantages such as faster construction, cost-effectiveness, and reduced environmental impact. Structural steel, on the other hand, refers to the use of steel beams, columns, and other structural elements in building construction.

Meaning

Prefabricated buildings and structural steel play a crucial role in the construction industry by providing innovative solutions for both residential and commercial projects. The GCC region, comprising countries such as Saudi Arabia, the United Arab Emirates, Qatar, Oman, Bahrain, and Kuwait, has witnessed a surge in infrastructure development, urbanization, and population growth, which has fueled the demand for prefabricated buildings and structural steel.

Executive Summary

The GCC prefabricated building and structural steel market have experienced substantial growth in recent years, driven by the increasing need for rapid and cost-effective construction solutions. Prefabricated buildings offer flexibility in design, improved quality control, and shorter construction time. Similarly, structural steel provides durability, strength, and versatility in construction projects. This report analyzes the key market insights, drivers, restraints, opportunities, regional analysis, competitive landscape, segmentation, category-wise insights, and key industry developments in the GCC prefabricated building and structural steel market.

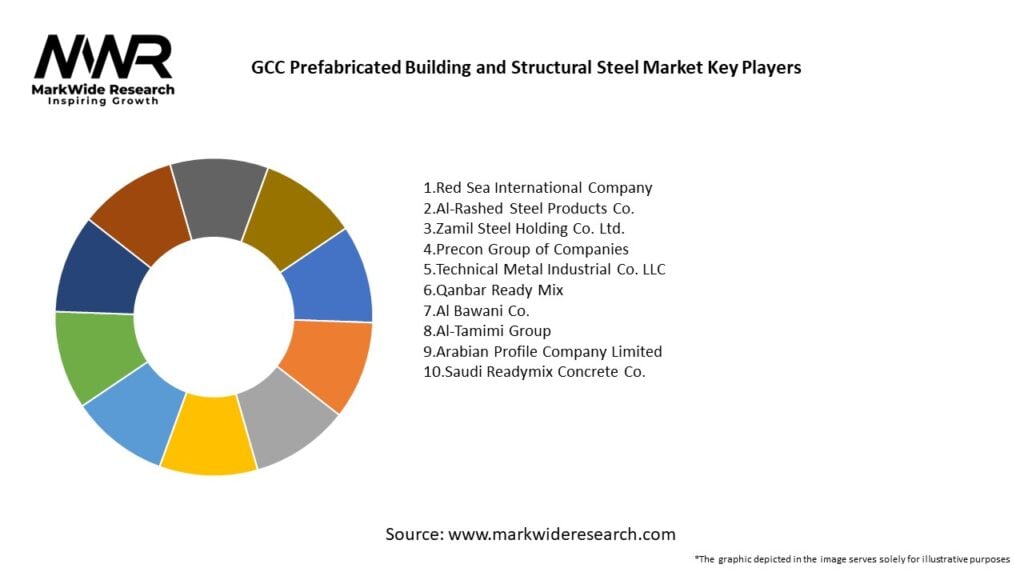

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The GCC prefabricated building and structural steel market are driven by various dynamic factors. The increasing focus on sustainable construction practices, the need for faster project completion, and the cost advantages offered by prefabricated buildings and structural steel are primary drivers. However, challenges related to skilled labor availability, initial investments, regulatory barriers, and limited awareness need to be addressed to unlock the market’s full potential. The market dynamics are influenced by government initiatives, infrastructure development, urbanization trends, and advancements in technology.

The GCC prefabricated building and structural steel market is influenced by several key factors:

Regional Analysis

The GCC prefabricated building and structural steel market exhibits varying trends across countries:

Competitive Landscape

Leading Companies in the GCC Prefabricated Building and Structural Steel Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The GCC prefabricated building and structural steel market can be segmented based on various criteria to provide a detailed understanding of its structure and dynamics:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the GCC prefabricated building and structural steel market can benefit in various ways:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic had both positive and negative impacts on the GCC prefabricated building and structural steel market. Initially, the market experienced disruptions due to supply chain disruptions, labor shortages, and project delays. However, the pandemic also highlighted the need for rapid construction solutions, leading to increased interest in prefabricated buildings and structural steel. The market adapted to the new normal by implementing safety protocols, remote working, and adopting technology to streamline operations. The pandemic served as a catalyst for digital transformation and increased awareness about the benefits of prefabrication.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the GCC prefabricated building and structural steel market appears promising. The increasing focus on sustainable construction, the need for faster project completion, and cost-effective solutions will drive the market growth. Technological advancements, such as robotics and 3D printing, will further improve the efficiency and quality of prefabricated buildings. The market will witness continued investments in infrastructure projects, urbanization, and the expansion of industrial and commercial sectors. With government support, increased customer awareness, and strategic collaborations, the GCC prefabricated building and structural steel market is poised for substantial growth in the coming years.

Conclusion

The GCC prefabricated building and structural steel market is experiencing significant growth driven by factors such as rapid urbanization, infrastructure development, and the need for sustainable construction practices. Prefabricated buildings and structural steel offer advantages in terms of faster construction, cost-effectiveness, and design flexibility. Although the market faces challenges related to skilled labor shortage, initial investments, and regulatory barriers, opportunities exist in affordable housing, green building initiatives, and renovation projects. Market participants should focus on skilled labor development, customer education, sustainability, and research and development to capitalize on the market’s future growth potential. With the right strategies, the GCC prefabricated building and structural steel market is expected to thrive in the years to come.

What is the GCC Prefabricated Building and Structural Steel?

The GCC Prefabricated Building and Structural Steel refers to construction methods that utilize pre-manufactured components and structural steel elements to create buildings efficiently. This approach is known for its speed, cost-effectiveness, and versatility in various applications such as residential, commercial, and industrial structures.

Who are the key players in the GCC Prefabricated Building and Structural Steel Market?

Key players in the GCC Prefabricated Building and Structural Steel Market include companies like Al Jaber Group, Emirates Steel, and Al-Futtaim Engineering, among others. These companies are known for their innovative solutions and significant contributions to the construction sector in the region.

What are the growth factors driving the GCC Prefabricated Building and Structural Steel Market?

The growth of the GCC Prefabricated Building and Structural Steel Market is driven by factors such as rapid urbanization, increasing demand for affordable housing, and the need for sustainable construction practices. Additionally, government initiatives promoting infrastructure development further enhance market growth.

What challenges does the GCC Prefabricated Building and Structural Steel Market face?

Challenges in the GCC Prefabricated Building and Structural Steel Market include fluctuating raw material prices, regulatory hurdles, and the need for skilled labor. These factors can impact project timelines and overall costs, posing challenges for industry stakeholders.

What opportunities exist in the GCC Prefabricated Building and Structural Steel Market?

Opportunities in the GCC Prefabricated Building and Structural Steel Market include the increasing adoption of green building technologies and the expansion of smart city projects. These trends are likely to drive demand for innovative prefabricated solutions that meet modern construction needs.

What trends are shaping the GCC Prefabricated Building and Structural Steel Market?

Trends shaping the GCC Prefabricated Building and Structural Steel Market include the integration of advanced technologies such as Building Information Modeling (BIM) and automation in manufacturing processes. Additionally, there is a growing emphasis on modular construction techniques that enhance efficiency and reduce waste.

GCC Prefabricated Building and Structural Steel Market:

| Segmentation | Details |

|---|---|

| Type | Modular Building, Panel System, Portal System, Others |

| Application | Residential, Commercial, Industrial, Infrastructure |

| Region | GCC (Gulf Cooperation Council) countries (Saudi Arabia, UAE, Qatar, Kuwait, Oman, Bahrain) |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the GCC Prefabricated Building and Structural Steel Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at