444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The GCC Conveyor Belt Market is experiencing significant growth, driven by various factors such as expanding industrialization, increasing infrastructure development, and rising automation in manufacturing processes. Conveyor belts are vital components in multiple industries, facilitating the movement of goods and materials within production lines and transportation systems. They play a crucial role in enhancing operational efficiency and reducing labor costs. The market for conveyor belts in the GCC region is witnessing substantial demand and is expected to continue its upward trajectory in the coming years.

Meaning

A conveyor belt is a mechanical device consisting of a continuous belt looped around pulleys, designed to move materials or products from one location to another. It operates on the principle of using friction for efficient transportation. Conveyor belts are widely utilized across diverse industries, including manufacturing, mining, logistics, and food processing. They enable the seamless movement of goods, providing a reliable and time-saving solution for material handling operations.

Executive Summary

The GCC Conveyor Belt Market has witnessed robust growth in recent years. The market is driven by the increasing adoption of automated systems, rising demand for efficient material handling, and the need for streamlining manufacturing processes. The conveyor belt industry in the GCC region offers immense growth opportunities for market players due to the region’s expanding industrial sector and infrastructure development initiatives. Key market participants are focusing on product innovation and strategic collaborations to gain a competitive edge in the market.

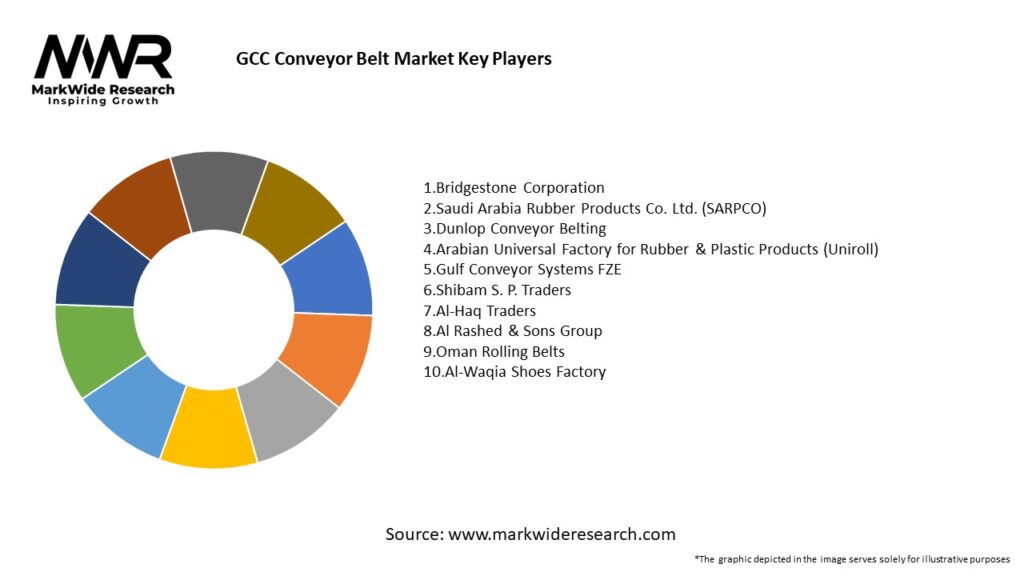

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

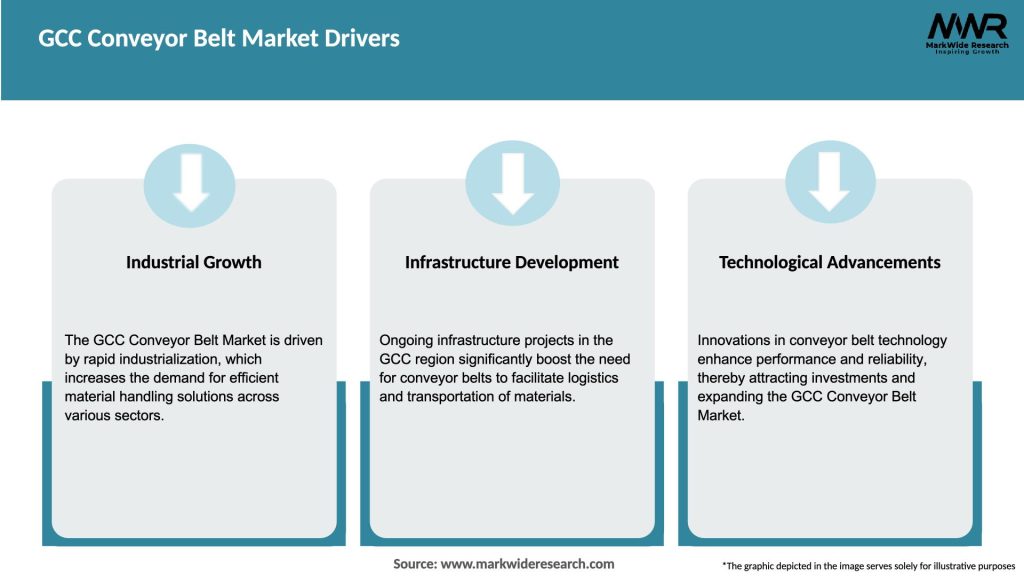

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The GCC Conveyor Belt Market is characterized by dynamic factors that influence its growth and development. These dynamics include market drivers, restraints, and opportunities that shape the industry’s landscape. The market is driven by the increasing industrialization, infrastructure development, and automation in manufacturing processes. However, challenges such as high costs, safety regulations, and the availability of alternative solutions can hinder market growth. The market dynamics highlight the need for continuous innovation and strategic partnerships to stay competitive and leverage emerging opportunities.

Regional Analysis

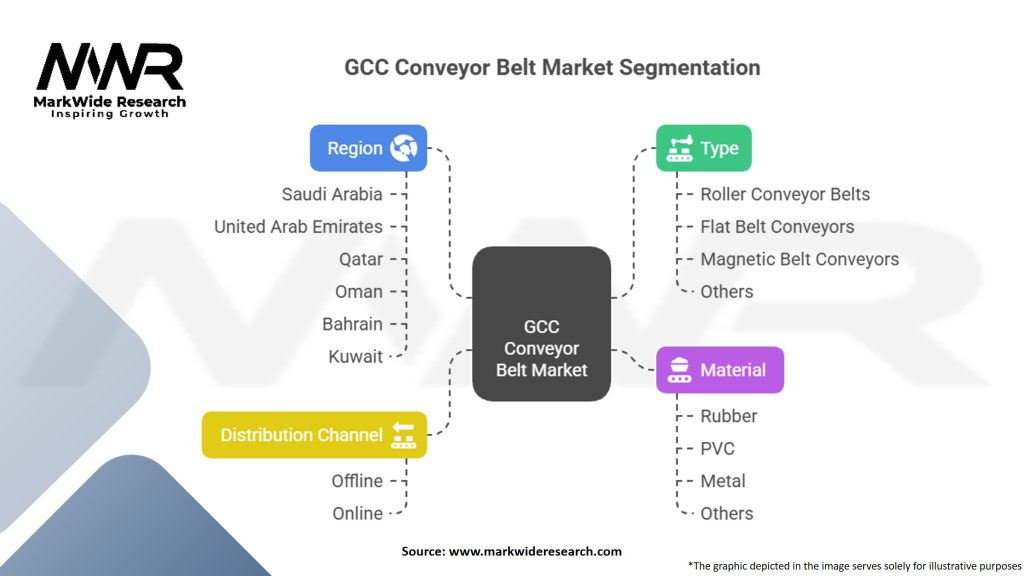

The GCC Conveyor Belt Market encompasses countries such as Saudi Arabia, the United Arab Emirates (UAE), Qatar, Oman, Bahrain, and Kuwait. The region is witnessing significant industrialization and infrastructure development, driving the demand for conveyor belts. Saudi Arabia and the UAE are the prominent markets in the region, driven by their robust manufacturing sectors and ambitious infrastructure projects. The GCC countries’ strategic geographical location also positions them as important logistics and transportation hubs, further augmenting the demand for conveyor belts in the region.

Competitive Landscape

Leading Companies in the GCC Conveyor Belt Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The GCC Conveyor Belt Market can be segmented based on the type of conveyor belt, application, and end-user industry.

Based on the type of conveyor belt, the market can be segmented into:

Based on application, the market can be segmented into:

Based on end-user industry, the market can be segmented into:

Segmentation allows market players to cater to specific customer needs and target their offerings accordingly, contributing to market growth.

Category-wise Insights

Understanding the various conveyor belt categories allows industry participants to identify market segments with growth potential and tailor their offerings accordingly.

Key Benefits for Industry Participants and Stakeholders

These key benefits highlight the value proposition of conveyor belt systems and attract industry participants and stakeholders to invest in their adoption.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

A comprehensive SWOT analysis helps industry participants identify their strengths, weaknesses, opportunities, and threats, allowing them to formulate effective strategies for sustainable growth.

Market Key Trends

These key trends shape the market landscape and present opportunities for industry participants to innovate and differentiate their offerings.

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the GCC Conveyor Belt Market. The outbreak led to disruptions in global supply chains, reduced manufacturing activities, and a decline in construction projects. The initial phase of the pandemic resulted in a temporary slowdown in the conveyor belt market as companies focused on maintaining essential operations and conserving cash.

However, the market gradually recovered as industries resumed their operations and implemented safety measures. The pandemic also highlighted the importance of automation and contactless material handling, driving the adoption of conveyor belt systems in various sectors. The growing e-commerce sector and increased demand for online shopping further fueled the need for efficient logistics and warehouse operations, boosting the demand for conveyor belts.

Market players responded to the pandemic by implementing stringent health and safety measures, accelerating digitization efforts, and focusing on product innovation. These strategies enabled companies to adapt to the changing market dynamics and cater to evolving customer requirements.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the GCC Conveyor Belt Market looks promising, driven by the region’s increasing industrialization, infrastructure development, and focus on automation. The market is expected to witness steady growth as industries continue to adopt conveyor belt systems to optimize material handling operations. Technological advancements, such as IoT integration and AI-based automation, will further enhance the capabilities of conveyor belts.

The expansion of the logistics and e-commerce sectors, along with the increasing emphasis on sustainable solutions, will continue to drive market demand. Market players need to remain agile, innovate, and collaborate to capture emerging opportunities and overcome challenges. By focusing on product differentiation, customer-centricity, and sustainability, companies can thrive in the evolving landscape of the GCC Conveyor Belt Market.

Conclusion

The GCC Conveyor Belt Market is experiencing significant growth, driven by industrialization, infrastructure development, and the need for efficient material handling. Conveyor belts play a vital role in various industries, offering benefits such as increased productivity, cost savings, and improved safety. The market presents opportunities for innovation, customization, and collaboration to cater to diverse customer needs.

While challenges such as high costs and safety regulations exist, market players can overcome them through continuous research and development, strategic partnerships, and a customer-centric approach. The COVID-19 pandemic has also impacted the market, highlighting the importance of automation and contactless material handling.

What is the GCC Conveyor Belt?

The GCC Conveyor Belt refers to the systems used for transporting materials across various industries in the Gulf Cooperation Council region. These belts are essential in sectors such as mining, manufacturing, and logistics, facilitating efficient movement of goods.

Who are the key players in the GCC Conveyor Belt Market?

Key players in the GCC Conveyor Belt Market include companies like Continental AG, Fenner Dunlop, and Habasit, which are known for their innovative solutions and extensive product ranges in conveyor technology, among others.

What are the main drivers of growth in the GCC Conveyor Belt Market?

The growth of the GCC Conveyor Belt Market is driven by increasing industrialization, the expansion of the logistics sector, and the rising demand for automation in material handling processes across various industries.

What challenges does the GCC Conveyor Belt Market face?

Challenges in the GCC Conveyor Belt Market include fluctuating raw material prices, the need for regular maintenance and upgrades, and competition from alternative material handling solutions that may offer lower costs.

What opportunities exist in the GCC Conveyor Belt Market?

Opportunities in the GCC Conveyor Belt Market include advancements in technology leading to more efficient and durable conveyor systems, as well as the growing focus on sustainability and eco-friendly materials in manufacturing processes.

What trends are shaping the GCC Conveyor Belt Market?

Trends in the GCC Conveyor Belt Market include the integration of smart technologies for monitoring and maintenance, the use of modular conveyor systems for flexibility, and an increasing emphasis on energy-efficient designs to reduce operational costs.

GCC Conveyor Belt Market

| Segmentation Details | Description |

|---|---|

| Type | Roller Conveyor Belts, Flat Belt Conveyors, Magnetic Belt Conveyors, Others |

| Material | Rubber, PVC, Metal, Others |

| Distribution Channel | Offline, Online |

| Region | Saudi Arabia, United Arab Emirates, Qatar, Oman, Bahrain, Kuwait) |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the GCC Conveyor Belt Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at