444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The fusion bonded epoxy powder coating market is witnessing steady growth due to its wide range of applications in various industries. Fusion bonded epoxy (FBE) powder coating is a dry powder coating process that is applied electrostatically to metal surfaces and then fused and cured to form a durable protective layer. This coating provides excellent corrosion resistance, chemical resistance, and adhesion, making it suitable for industries such as oil and gas, automotive, construction, and electronics.

Meaning

Fusion bonded epoxy powder coating is a type of coating that involves the application of an electrostatically charged dry powder to metal surfaces. The powder adheres to the metal due to the electrostatic attraction and is then fused and cured to create a strong and durable coating. This process ensures a uniform and high-quality finish that provides superior protection against corrosion, abrasion, and chemicals.

Executive Summary

The fusion bonded epoxy powder coating market has been experiencing significant growth in recent years. This can be attributed to the increasing demand for corrosion-resistant coatings in various industries. The market is characterized by the presence of both established players and new entrants, creating a competitive landscape. Key market players are focusing on research and development activities to enhance the performance of fusion bonded epoxy powder coatings and expand their product portfolios.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

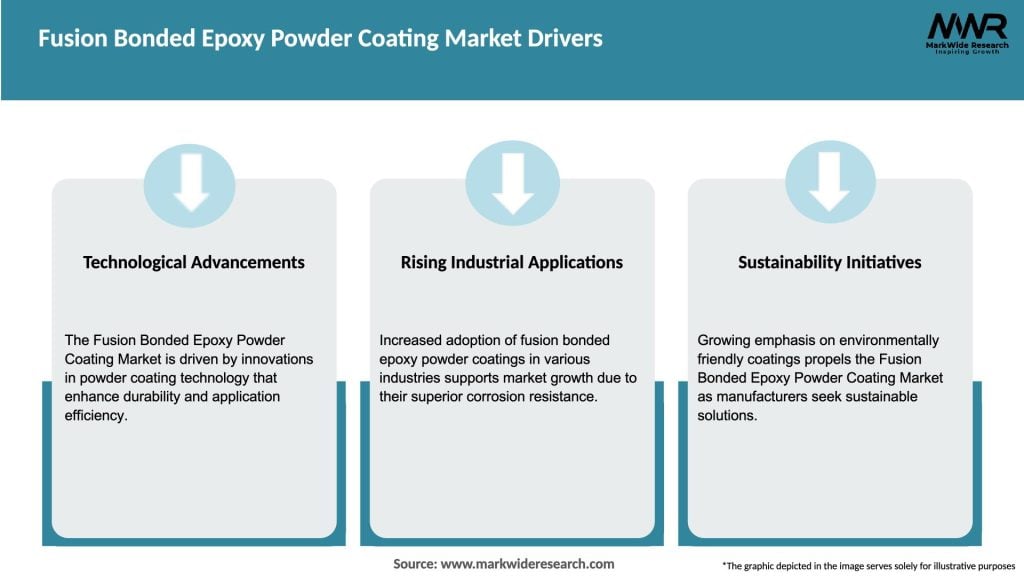

Market Drivers

Oil & Gas Infrastructure: Aging pipeline networks require rehabilitation and new-build coatings for corrosion mitigation.

Industrial Equipment: FBE provides chemical and abrasion resistance for agricultural and construction machinery.

Regulatory Standards: API and NACE corrosion control guidelines mandate protective coating use on buried/immersed assets.

Lifecycle Cost Savings: FBE’s durability reduces maintenance frequency and downtime over asset lifetime.

Sustainability Focus: Powder coatings generate minimal VOC emissions compared to liquid coatings.

Market Restraints

High Processing Temperatures: Typical bake cycles (180–200 °C) can limit substrate compatibility and energy efficiency.

Surface Preparation Need: Peening, sandblasting, or grit blast prior to FBE application adds process steps and cost.

Repair Challenges: Field repair of damaged FBE requires specialized portable curing ovens and trained crews.

Capital Equipment Costs: Powder spray booths and ovens represent significant upfront investment.

Competition from Liquid Epoxy: In some applications, liquid epoxies offer lower-temperature cures and simpler application.

Market Opportunities

Low-Cure FBE Formulations: Development of powders that cure at <150 °C for broader substrate use.

Smart Coatings: Incorporating corrosion-indicating pigments that change color upon substrate breach.

Field Repair Kits: Portable powder application and curing solutions for remote maintenance.

Adhesion-Enhancing Primers: Two-in-one primer+FBE products to simplify multi-layer pipeline coating.

Recycled Powder Programs: Closed-loop recycling systems for overspray capture and reuse.

Market Dynamics

The fusion bonded epoxy powder coating market is driven by various factors, including the increasing need for corrosion protection, infrastructure development projects, and advancements in coating technologies. However, the market faces challenges such as high initial costs, environmental regulations, and a shortage of skilled labor. Nevertheless, there are opportunities for growth, such as the expanding adoption of fusion bonded epoxy powder coatings in emerging economies, the automotive and transportation industry, and the development of sustainable coating formulations.

Regional Analysis

The fusion bonded epoxy powder coating market is segmented into several regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. North America holds a significant share in the market due to the presence of established players and the growing demand for corrosion-resistant coatings in industries such as oil and gas and infrastructure. Asia Pacific is anticipated to witness substantial growth, driven by the expanding automotive and electronics sectors in countries like China and India.

Competitive Landscape

Leading Companies in the Fusion Bonded Epoxy Powder Coating Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

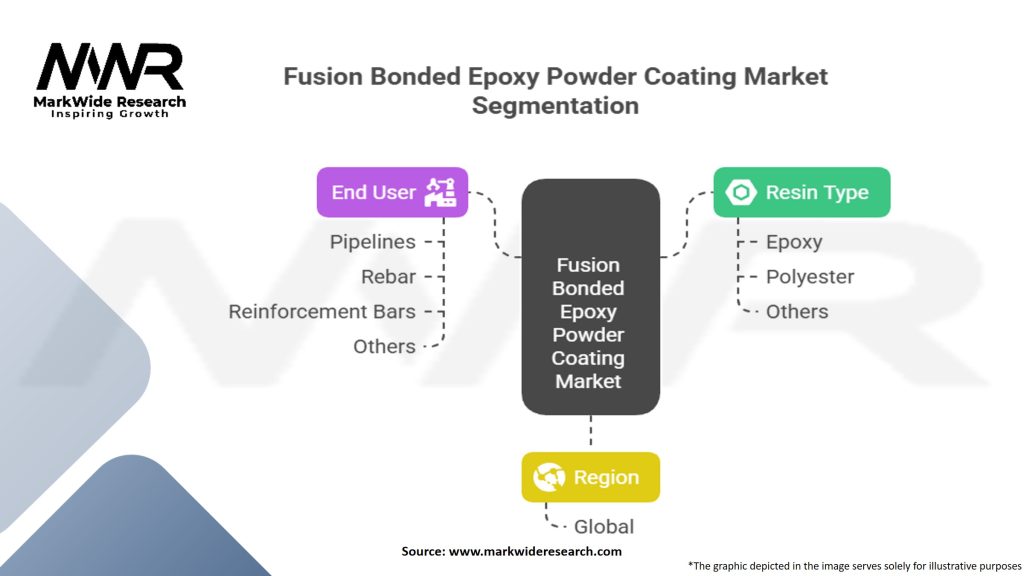

Segmentation

The fusion bonded epoxy powder coating market can be segmented based on resin type, application, end-use industry, and region. By resin type, the market can be categorized into epoxy-polyester hybrids, pure epoxy, and others. Application-wise, the market can be divided into pipes and rebar, automotive parts, appliances, construction equipment, and others. End-use industries for fusion bonded epoxy powder coatings include oil and gas, automotive, infrastructure, water and wastewater treatment, electrical and electronics, and others.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The fusion bonded epoxy powder coating market experienced a temporary setback due to the COVID-19 pandemic. The global lockdowns and disruptions in supply chains affected the demand for coatings in various industries. However, as economies recover and industries resume their operations, the market is expected to regain momentum. The need for corrosion protection and infrastructure development projects will drive the demand for fusion bonded epoxy powder coatings in the post-pandemic era.

Key Industry Developments

Analyst Suggestions

Future Outlook

The fusion bonded epoxy powder coating market is projected to grow steadily in the coming years. The demand for corrosion-resistant coatings and the expansion of industries such as oil and gas, automotive, and infrastructure will drive market growth. Technological advancements and the development of sustainable coating formulations will further enhance market prospects. However, challenges such as high initial costs and environmental regulations need to be addressed to ensure sustained growth.

Conclusion

The fusion bonded epoxy powder coating market offers immense opportunities for corrosion protection and enhanced durability across various industries. With its excellent adhesion, corrosion resistance, and chemical resistance properties, fusion bonded epoxy powder coatings have become a preferred choice in applications ranging from pipes and automotive parts to appliances and construction equipment. As the market continues to evolve, manufacturers should focus on innovation, sustainability, and expanding their presence in emerging markets to capitalize on the growing demand for these coatings.

What is Fusion Bonded Epoxy Powder Coating?

Fusion Bonded Epoxy Powder Coating is a type of coating that provides a durable and corrosion-resistant finish, commonly used in industrial applications, automotive parts, and outdoor furniture.

What are the key players in the Fusion Bonded Epoxy Powder Coating Market?

Key players in the Fusion Bonded Epoxy Powder Coating Market include companies like PPG Industries, AkzoNobel, and Sherwin-Williams, among others.

What are the growth factors driving the Fusion Bonded Epoxy Powder Coating Market?

The growth of the Fusion Bonded Epoxy Powder Coating Market is driven by increasing demand for durable coatings in automotive and construction industries, as well as the rising focus on environmentally friendly coating solutions.

What challenges does the Fusion Bonded Epoxy Powder Coating Market face?

Challenges in the Fusion Bonded Epoxy Powder Coating Market include the high cost of raw materials and the need for specialized application equipment, which can limit market growth.

What opportunities exist in the Fusion Bonded Epoxy Powder Coating Market?

Opportunities in the Fusion Bonded Epoxy Powder Coating Market include the development of new formulations for enhanced performance and the expansion into emerging markets with growing industrial sectors.

What trends are shaping the Fusion Bonded Epoxy Powder Coating Market?

Trends in the Fusion Bonded Epoxy Powder Coating Market include the increasing adoption of advanced powder coating technologies and a shift towards sustainable practices in manufacturing processes.

Fusion Bonded Epoxy Powder Coating Market

| Segmentation Details | Information |

|---|---|

| Resin Type | Epoxy, Polyester, Others |

| End User | Pipelines, Rebar, Reinforcement Bars, Others |

| Region | Global |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Fusion Bonded Epoxy Powder Coating Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at