444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview:

The furnace boats market encompasses the manufacturing, distribution, and sale of specialized boats or carriers used in high-temperature furnaces for the transportation and processing of materials in various industrial applications. Furnace boats play a crucial role in facilitating the heat treatment, annealing, sintering, and brazing processes across industries such as semiconductor, automotive, aerospace, and electronics manufacturing.

Meaning:

Furnace boats, also known as crucibles or trays, are refractory vessels or containers designed to hold and transport materials within high-temperature furnaces. These boats are typically made from materials such as graphite, ceramics, or refractory metals capable of withstanding extreme temperatures and corrosive environments encountered during thermal processing operations.

Executive Summary:

The furnace boats market is driven by the growing demand for advanced materials, miniaturization of electronic components, and technological advancements in materials science and thermal processing techniques. Manufacturers of furnace boats are focusing on product innovation, material optimization, and customization to meet the evolving needs of end-users and enhance the efficiency and performance of thermal processing operations.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The furnace boats market dynamics are influenced by factors such as technological advancements, industry regulations, competitive landscape, macroeconomic trends, and end-user preferences, shaping market demand, product development, and business strategies.

Regional Analysis:

The adoption of furnace boats varies by region based on factors such as industrial manufacturing activity, technological infrastructure, regulatory environment, and market maturity. Regions with high concentrations of semiconductor fabrication facilities, research institutions, and aerospace industries represent key markets for furnace boats and thermal processing equipment.

Competitive Landscape:

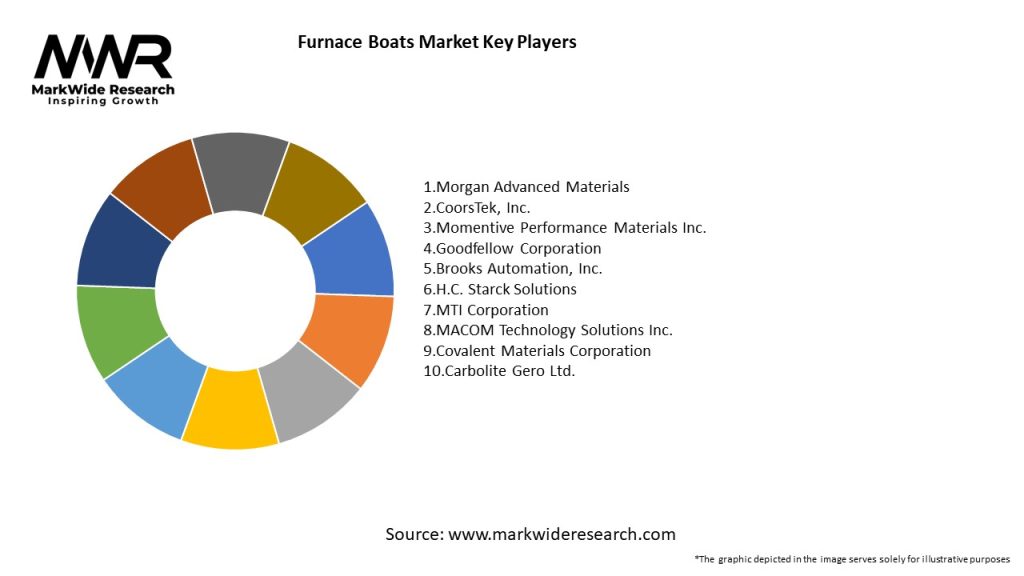

Leading Companies in the Furnace Boats Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

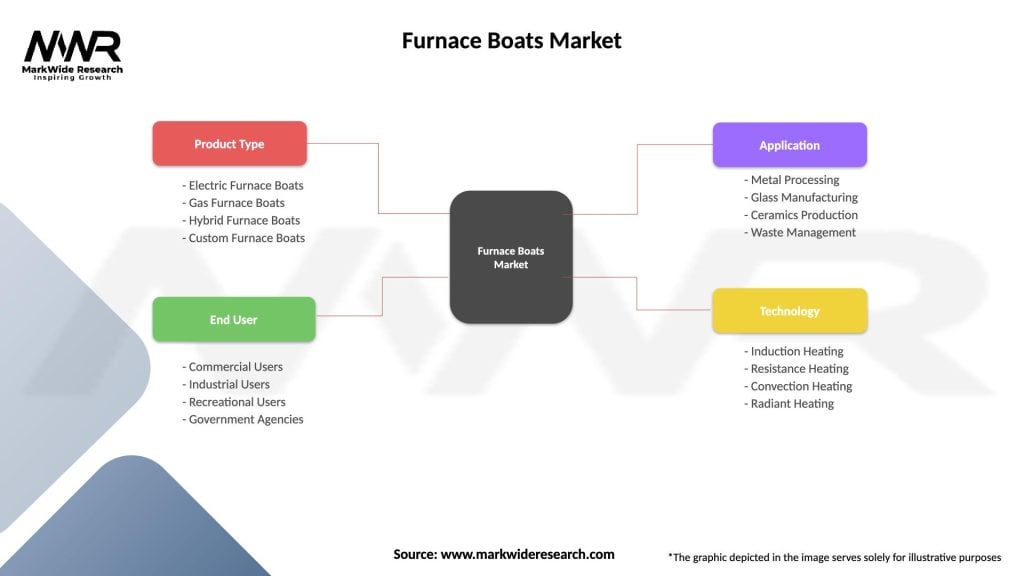

Segmentation:

The furnace boats market can be segmented based on factors such as boat material, geometry, capacity, application, end-user industry, and geographic region, enabling targeted marketing, product development, and customer engagement strategies to address specific market segments and user needs.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Strengths

• The furnace boats market benefits from advanced manufacturing techniques that enhance product durability and efficiency in high-temperature applications.

• Strong demand from industries such as metal processing and ceramics supports consistent growth and innovation within the sector.

• Established supply chains and partnerships with raw material suppliers ensure a steady flow of quality inputs for furnace boat production.

• A growing emphasis on energy efficiency and sustainability in manufacturing processes positions furnace boats as a critical component in reducing operational costs.

Weaknesses

• The high initial investment required for furnace boat technology can deter smaller companies from entering the market.

• Limited awareness and understanding of the applications and benefits of furnace boats among potential customers can restrict market expansion.

• Dependence on a few key industries for demand may expose the market to fluctuations in those sectors’ economic conditions.

• The complexity of manufacturing processes can lead to higher operational costs and potential quality control issues.

Opportunities

• Increasing adoption of automation and smart technologies in industrial processes presents opportunities for integrating advanced furnace boat solutions.

• Expanding markets in developing regions, where industrialization is on the rise, offer significant growth potential for furnace boat manufacturers.

• The trend towards sustainable manufacturing practices encourages investment in furnace boats that minimize waste and energy consumption.

• Ongoing research and development initiatives can lead to innovative materials and designs, enhancing the performance and application range of furnace boats.

Threats

• Intense competition from alternative heating solutions may impact market share and pricing strategies for furnace boat manufacturers.

• Regulatory changes regarding environmental standards and emissions can impose additional compliance costs on manufacturers.

• Economic downturns and fluctuations in raw material prices could adversely affect production costs and profit margins in the furnace boats market.

• Technological advancements in competing industries may render traditional furnace boats less relevant, posing a risk to long-term market viability.

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic has affected the furnace boats market by disrupting supply chains, delaying capital investments, and reducing industrial activity in some sectors. However, the resilience of critical industries, such as semiconductor manufacturing, and the adoption of remote work and digital solutions have mitigated the impact and accelerated recovery in the post-pandemic period.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The future outlook for the furnace boats market is optimistic, driven by the increasing demand for advanced materials, precision manufacturing, and high-temperature processing capabilities across diverse industries such as semiconductor, aerospace, automotive, and medical devices. However, challenges such as material innovation, regulatory compliance, and geopolitical uncertainties may impact market growth and competitiveness in the global marketplace.

Conclusion:

In conclusion, the furnace boats market plays a critical role in supporting advanced manufacturing processes, research endeavors, and technological innovations by providing reliable, high-performance vessels for thermal processing operations. By leveraging technological advancements, embracing sustainability practices, and fostering collaboration and innovation, stakeholders in the furnace boats market can capitalize on growth opportunities, address market challenges, and sustain competitiveness in an increasingly dynamic and competitive global marketplace.

What is a Furnace Boat?

A Furnace Boat is a specialized vessel used in various industrial applications, primarily for transporting molten materials such as metals and glass. These boats are designed to withstand high temperatures and ensure safe handling of hot substances.

What are the key players in the Furnace Boats Market?

Key players in the Furnace Boats Market include companies like Harsco Corporation, Houghton International, and Hempel A/S, which are known for their innovative solutions in high-temperature transport. These companies focus on enhancing the efficiency and safety of furnace boat operations, among others.

What are the growth factors driving the Furnace Boats Market?

The Furnace Boats Market is driven by the increasing demand for efficient metal processing and the growth of the glass manufacturing industry. Additionally, advancements in materials technology are enhancing the performance and durability of furnace boats.

What challenges does the Furnace Boats Market face?

Challenges in the Furnace Boats Market include the high costs associated with manufacturing and maintaining these specialized vessels. Furthermore, regulatory compliance regarding safety standards can pose additional hurdles for manufacturers.

What opportunities exist in the Furnace Boats Market?

Opportunities in the Furnace Boats Market include the potential for innovation in materials that can withstand higher temperatures and the expansion of applications in renewable energy sectors. Additionally, emerging markets are presenting new avenues for growth.

What trends are shaping the Furnace Boats Market?

Trends in the Furnace Boats Market include the increasing adoption of automation and smart technologies to enhance operational efficiency. There is also a growing focus on sustainability, with manufacturers exploring eco-friendly materials and processes.

Furnace Boats Market

| Segmentation Details | Description |

|---|---|

| Product Type | Electric Furnace Boats, Gas Furnace Boats, Hybrid Furnace Boats, Custom Furnace Boats |

| End User | Commercial Users, Industrial Users, Recreational Users, Government Agencies |

| Application | Metal Processing, Glass Manufacturing, Ceramics Production, Waste Management |

| Technology | Induction Heating, Resistance Heating, Convection Heating, Radiant Heating |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Furnace Boats Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at