444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Fluid loss additives play a crucial role in the oil and gas industry, particularly in drilling operations. These additives are designed to reduce fluid loss from drilling fluids, helping maintain stability and efficiency in the drilling process. The fluid loss additives market has witnessed significant growth in recent years, driven by the increasing demand for efficient drilling operations and the rising exploration activities in the oil and gas sector.

Meaning

Fluid loss additives are chemicals or substances added to drilling fluids to control the filtration rate and prevent excessive fluid loss into the formation during drilling. They create a filter cake on the wellbore walls, reducing the permeability and fluid loss into the surrounding rock formations. By minimizing fluid loss, these additives help maintain wellbore stability, prevent formation damage, and improve drilling efficiency.

Executive Summary

The fluid loss additives market is experiencing substantial growth, driven by the escalating demand for oil and gas exploration and production activities. The market is witnessing the development of advanced fluid loss additives that offer enhanced performance and environmental sustainability. With the increasing complexity of drilling operations and the need for efficient fluid management, the demand for fluid loss additives is expected to continue growing in the coming years.

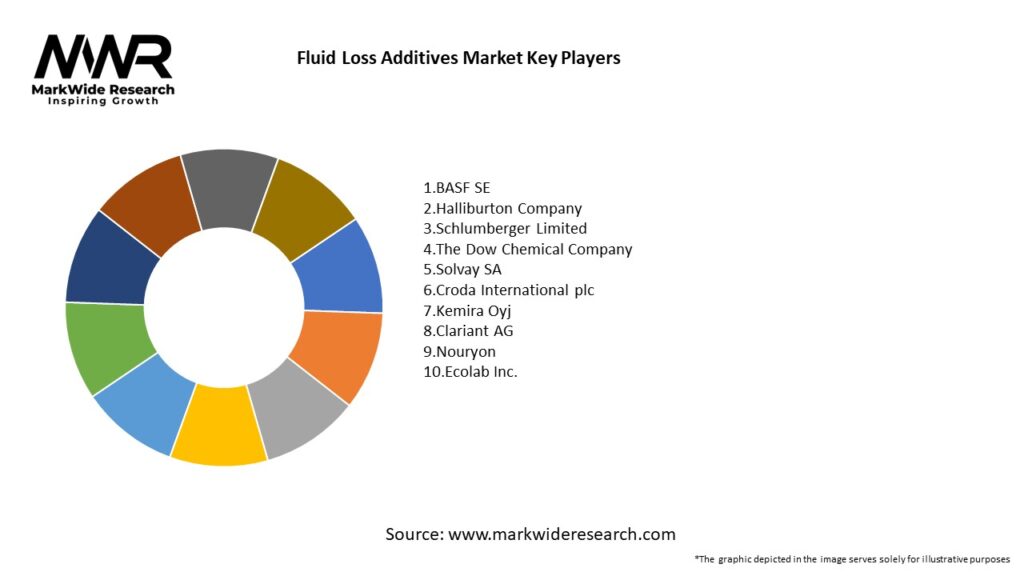

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Growth: The Fluid Loss Additives Market is projected to grow at a compound annual growth rate (CAGR) of XX% from 2024 to 2030.

Demand in Oil and Gas: The oil and gas industry is the largest consumer of fluid loss additives, with increasing drilling activities in both conventional and unconventional oil and gas fields driving market demand.

Environmentally Friendly Products: There is a growing trend towards the development of eco-friendly fluid loss additives that minimize the environmental impact of drilling and construction activities.

Advancements in Technology: Technological innovations in fluid loss additive formulations, including the development of high-performance additives that offer enhanced fluid loss control, are boosting market growth.

Market Drivers

Several factors are driving the growth of the Fluid Loss Additives Market:

Increase in Drilling Activities: As the demand for energy continues to rise, the exploration and drilling activities for oil and gas, particularly in unconventional reserves such as shale and deep-water fields, are driving the demand for fluid loss additives.

Infrastructure Expansion: The growing demand for infrastructure development in emerging economies is boosting the use of fluid loss additives in cement slurries and construction materials.

Technological Advancements: Innovations in fluid loss additive formulations, including those that offer higher performance and environmental benefits, are driving the market by improving operational efficiency and reducing environmental impact.

Regulatory Pressure: Stricter environmental regulations in industries such as oil and gas and construction are prompting the development and adoption of eco-friendly fluid loss additives, which can further fuel market growth.

Need for Operational Efficiency: Fluid loss additives help improve operational efficiency, reduce downtime, and prevent the loss of valuable drilling fluids, driving demand in drilling and cementing applications.

Market Restraints

Despite its growth, the Fluid Loss Additives Market faces several challenges:

High Cost of Advanced Additives: The development and production of high-performance and environmentally friendly fluid loss additives can be expensive, which may deter small- and medium-sized businesses from adopting these solutions.

Environmental Concerns: While there is an increasing demand for eco-friendly additives, some traditional fluid loss additives still have adverse environmental impacts, which could hinder market growth in certain regions with stricter environmental regulations.

Complex Formulation Requirements: The formulation of fluid loss additives requires a deep understanding of chemistry and material properties, which can make the production and application of these additives complex and expensive.

Market Fragmentation: The market for fluid loss additives is highly fragmented, with many small and medium-sized players competing with large multinational companies. This fragmentation can make it difficult for companies to scale operations and achieve economies of scale.

Market Opportunities

The Fluid Loss Additives Market presents several opportunities for growth:

Development of Eco-Friendly Additives: The increasing emphasis on environmental sustainability presents opportunities for the development of biodegradable and non-toxic fluid loss additives, which can help companies comply with environmental regulations and attract environmentally conscious customers.

Rising Demand in Emerging Markets: The growing industrialization and urbanization in emerging markets such as India, China, and Brazil are creating new opportunities for fluid loss additives in both the oil and gas and construction sectors.

Advanced Fluid Loss Control Technologies: The demand for higher-performance fluid loss additives, including those with enhanced temperature and pressure resistance, offers opportunities for innovation in the formulation of advanced additives.

Integration with Smart Technologies: The integration of fluid loss additives with smart technologies, such as sensors and IoT devices, could enable real-time monitoring and optimization of fluid loss control, improving operational efficiency and reducing costs.

Market Dynamics

The Fluid Loss Additives Market is influenced by several dynamic factors:

Technological Advancements: Continuous improvements in chemical formulations and the development of multifunctional fluid loss additives are driving the market. These innovations improve the performance of additives and help address the challenges posed by more complex drilling operations.

Environmental Impact: As environmental regulations become stricter, there is an increasing demand for sustainable fluid loss additives that minimize environmental damage. This is driving the development of biodegradable additives and other eco-friendly solutions.

Industry Consolidation: Larger players in the market are engaging in mergers and acquisitions to expand their product offerings, enhance their market presence, and capitalize on new growth opportunities, leading to a more consolidated competitive landscape.

Regional Analysis

The fluid loss additives market can be analyzed based on regional segmentation, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its unique characteristics and market dynamics that influence the demand for fluid loss additives.

Competitive Landscape

Leading Companies in the Fluid Loss Additives Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

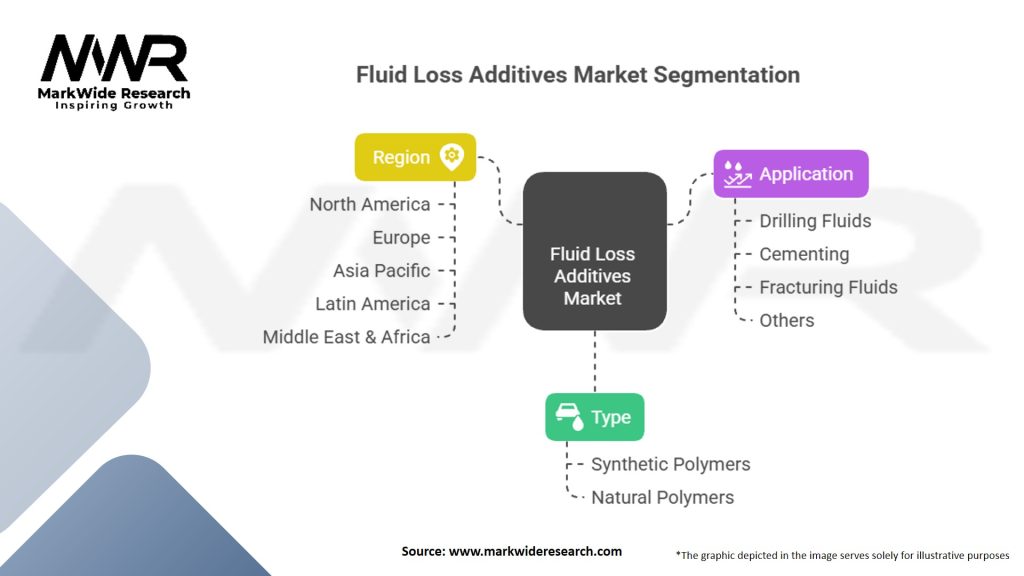

Segmentation

The Fluid Loss Additives Market can be segmented based on several criteria, providing a comprehensive view of its structure and opportunities:

By Product Type:

Polymeric Additives:

Polymers that form an effective filter cake to control fluid loss.

Fibrous Additives:

Materials that reinforce the filter cake structure, improving its integrity.

Combination Additives:

Formulations that combine polymers, fibers, and other chemicals to achieve enhanced performance.

By Application:

Conventional Drilling:

Use in traditional oil and gas drilling operations.

Unconventional Drilling:

Applications in shale, tight, and deepwater reservoirs where fluid loss control is critical.

Enhanced Recovery Operations:

Utilized in secondary and tertiary recovery processes to optimize production efficiency.

By Distribution Channel:

Direct Sales:

Sales through manufacturer-owned channels and direct industrial contracts.

Distributors and Dealers:

Third-party networks that facilitate broad market reach.

Online Platforms:

Digital channels enabling direct ordering and supply chain transparency.

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Category-wise Insights

Each segment within the Fluid Loss Additives Market offers unique benefits and meets specific industry needs:

Polymeric Additives:

Provide superior filter cake formation and are widely used in a variety of drilling environments.

Fibrous Additives:

Enhance the mechanical strength of the filter cake, particularly in high-pressure formations.

Combination Additives:

Offer optimized performance by leveraging the benefits of both polymers and fibers, suitable for complex drilling conditions.

Application-Specific Solutions:

Customized formulations tailored for conventional, unconventional, and enhanced recovery operations address the unique challenges of each drilling scenario.

Key Benefits for Industry Participants and Stakeholders

The Fluid Loss Additives Market offers several strategic benefits:

Improved Drilling Efficiency:

Effective fluid loss control reduces non-productive time and mitigates formation damage, leading to higher operational efficiency.

Cost Savings:

By reducing the incidence of drilling complications, fluid loss additives help lower overall drilling costs.

Enhanced Environmental Compliance:

Advanced additive formulations minimize environmental impact by reducing the volume of drilling fluids lost to the formation.

Operational Flexibility:

A diverse range of additive solutions enables operators to tailor fluid loss control to specific well conditions and geological formations.

Competitive Differentiation:

Adoption of innovative and efficient fluid loss control technologies can provide a competitive edge in a challenging market.

SWOT Analysis

Strengths:

Effective Fluid Management:

High-performance additives significantly reduce fluid loss and improve drilling stability.

Technological Leadership:

Continuous innovation in chemical formulations enhances product performance and operational efficiency.

Versatile Applications:

The broad applicability across different drilling environments and reservoir types strengthens market resilience.

Weaknesses:

High Raw Material Costs:

Fluctuations in the cost of polymers and other key raw materials can impact production expenses.

Regulatory Challenges:

Compliance with stringent environmental and safety regulations may increase operational costs.

Integration Issues:

Variability in drilling fluid compositions and well conditions can complicate the effective application of additives.

Opportunities:

Emerging Markets:

Increased drilling activity in emerging regions offers substantial opportunities for market expansion.

Product Innovation:

Development of eco-friendly and high-performance additives can capture demand from environmentally conscious operators.

Digital Integration:

Incorporation of digital monitoring tools in drilling operations can optimize additive usage and improve performance.

Strategic Collaborations:

Partnerships between chemical manufacturers and drilling service providers can accelerate product development and market penetration.

Threats:

Economic Uncertainty:

Global economic fluctuations and reduced investment in exploration can negatively impact demand.

Intense Competition:

Competition from alternative drilling fluid additives and established petrochemical products may pressure pricing.

Technological Disruptions:

Rapid changes in drilling technology could render existing additive formulations less effective if not continuously updated.

Market Key Trends

Key trends shaping the Fluid Loss Additives Market include:

Focus on Sustainability:

Increasing pressure to adopt eco-friendly drilling practices is driving the development of biodegradable and low-toxicity additives.

Technological Advancements:

Innovations in polymer science and composite additive formulations are enhancing performance under extreme drilling conditions.

Digital Transformation:

The integration of real-time monitoring and data analytics in drilling operations is enabling optimized additive management and improved drilling outcomes.

Customized Solutions:

Demand for tailored additive formulations to meet the specific requirements of various reservoir types is growing.

Global Market Consolidation:

Strategic mergers and acquisitions are streamlining supply chains and fostering standardization within the market.

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the Fluid Loss Additives Market:

Supply Chain Disruptions:

Temporary interruptions in the supply of raw materials have led to increased volatility in production costs.

Shift in Operational Priorities:

Operators have increasingly focused on cost optimization and efficiency improvements during the pandemic, indirectly supporting the adoption of high-performance additives.

Digital Acceleration:

The pandemic accelerated the adoption of digital monitoring and process control technologies, enhancing the efficient use of fluid loss additives.

Economic Fluctuations:

While some drilling activities were temporarily delayed, the overall long-term demand for efficient drilling operations remains strong.

Enhanced R&D Investment:

Increased focus on operational efficiency during the pandemic spurred investments in research and development, driving innovation in additive formulations.

Key Industry Developments

Recent developments in the market include:

Advanced Formulation Launches:

Introduction of next-generation fluid loss additives with enhanced performance in high-temperature and high-pressure conditions.

Strategic Alliances:

Collaborations between major chemical companies and drilling service providers are accelerating technology transfer and product innovation.

Market Consolidation:

Mergers and acquisitions among key players are leading to streamlined supply chains and improved economies of scale.

Digital Integration Initiatives:

Deployment of digital tools and real-time monitoring systems in drilling operations is optimizing the application of fluid loss additives.

Focus on Sustainability:

Development of eco-friendly additives and improved waste management practices are aligning product offerings with evolving environmental regulations.

Analyst Suggestions

Industry analysts recommend the following strategies:

Enhance Research and Development:

Invest in R&D to develop innovative, cost-effective, and environmentally sustainable additive formulations.

Strengthen Supply Chain Management:

Diversify raw material sourcing and improve production infrastructure to mitigate supply chain disruptions and cost volatility.

Expand Digital Capabilities:

Leverage digital monitoring and data analytics to optimize fluid loss control and improve drilling efficiency.

Target Emerging Markets:

Focus on expanding market presence in emerging regions through tailored product offerings and strategic partnerships.

Form Strategic Collaborations:

Collaborate with drilling service providers and technology partners to integrate advanced additives into comprehensive drilling solutions.

Future Outlook

The future of the Fluid Loss Additives Market appears promising, driven by several key factors:

Ongoing Technological Innovation:

Continued advancements in additive formulations and digital integration will enhance drilling efficiency and reduce operational costs.

Sustained Drilling Activity:

Global expansion of exploration and production activities, particularly in emerging markets, will drive long-term demand.

Focus on Sustainability:

Increased regulatory and environmental pressures will spur the development and adoption of eco-friendly additives.

Economic Resilience:

Despite short-term economic uncertainties, the essential nature of efficient drilling operations ensures steady market demand.

Market Consolidation:

Strategic mergers and acquisitions will streamline the competitive landscape and promote industry standardization.

Conclusion

The Fluid Loss Additives Market is set to play a pivotal role in enhancing the efficiency and environmental compliance of drilling operations worldwide. With continuous technological innovation, a strong focus on sustainability, and the integration of digital tools, the market is poised for robust long-term growth.

The fluid loss additives market plays a crucial role in the oil and gas industry by ensuring efficient drilling operations and wellbore stability. With the rising demand for energy and the exploration of new reserves, the market offers significant opportunities for industry participants. By focusing on technological advancements, sustainability, and market expansion strategies, companies can capitalize on these opportunities and thrive in the competitive landscape of the fluid loss additives market.

What are Fluid Loss Additives?

Fluid Loss Additives are chemical compounds used in drilling fluids to reduce the loss of fluid into porous formations. They help maintain the stability of the wellbore and improve the efficiency of drilling operations.

What are the key companies in the Fluid Loss Additives Market?

Key companies in the Fluid Loss Additives Market include Halliburton, Schlumberger, BASF, and Newpark Resources, among others.

What are the drivers of growth in the Fluid Loss Additives Market?

The growth of the Fluid Loss Additives Market is driven by the increasing demand for efficient drilling operations, the expansion of oil and gas exploration activities, and advancements in additive technologies.

What challenges does the Fluid Loss Additives Market face?

The Fluid Loss Additives Market faces challenges such as stringent environmental regulations, the high cost of advanced additives, and competition from alternative technologies.

What opportunities exist in the Fluid Loss Additives Market?

Opportunities in the Fluid Loss Additives Market include the development of eco-friendly additives, the growing trend of deepwater drilling, and the increasing adoption of automation in drilling processes.

What trends are shaping the Fluid Loss Additives Market?

Trends in the Fluid Loss Additives Market include the rise of sustainable drilling practices, the integration of digital technologies for monitoring fluid performance, and the focus on enhancing the efficiency of drilling fluids.

Fluid Loss Additives Market

| Segmentation | Details |

|---|---|

| Type | Synthetic Polymers, Natural Polymers |

| Application | Drilling Fluids, Cementing, Fracturing Fluids, Others |

| Region | Global (including regions such as North America, Europe, Asia Pacific, Latin America, Middle East & Africa) |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Fluid Loss Additives Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at