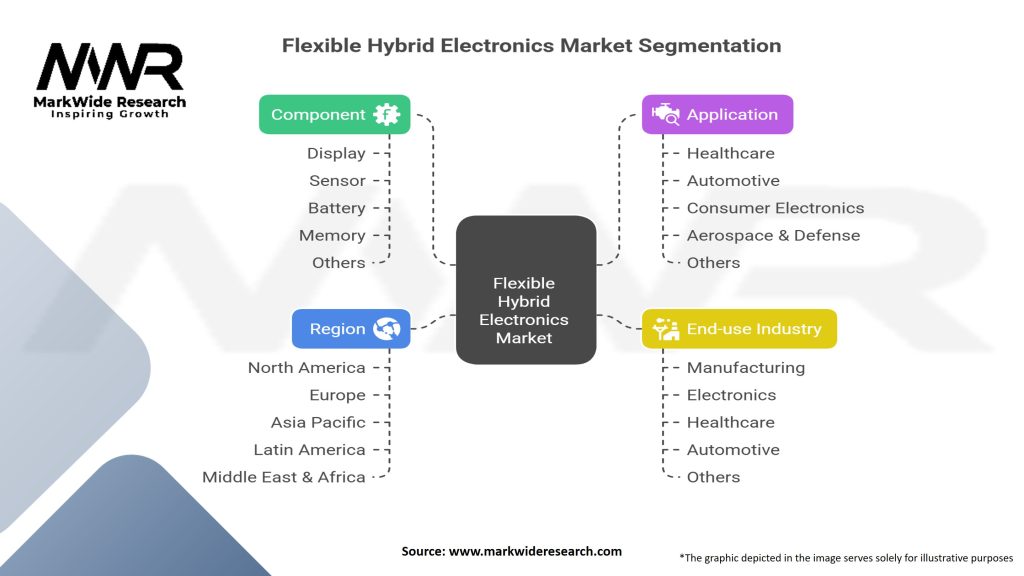

Segmentation

-

By Substrate: Polyimide, PET, Paper, Textile

-

By Component Type: Printed Interconnects, Flexible Sensors, Embedded ICs, Flexible Batteries/Power Sources

-

By Application: Wearables (Healthcare, Fitness), Smart Packaging, Industrial IoT, Automotive Interiors, Consumer Electronics

-

By Manufacturing Technique: Inkjet Printing, Screen Printing, Roll-to-Roll Lamination, Pick-and-Place Hybrid Assembly

Category-wise Insights

-

Healthcare Wearables: Flexible ECG, temperature, and hydration sensors laminated onto skin-patches for continuous monitoring.

-

Smart Packaging: Printed NFC and e-paper labels for dynamic pricing, authentication, and consumer engagement.

-

Industrial IoT: Rugged FHE sensor strips for vibration and temperature monitoring on rotating machinery.

-

Automotive Interiors: Conformal lighting and touch-sensitive controls embedded into dashboards and seats.

-

Consumer Electronics: Foldable displays and flexible keypads integrating rigid driver ICs into bendable circuits.

Key Benefits for Industry Participants and Stakeholders

-

Design Freedom: Unconstrained form factors enable product differentiation and ergonomic enhancements.

-

Cost Efficiency: FHE reduces part counts and assembly steps, lowering BOM costs at high volumes.

-

Lightweight Solutions: Thinner, lighter electronics improve comfort in wearables and reduce weight in automotive and aerospace applications.

-

Rapid Innovation: Prototype-to-production cycles accelerate, thanks to digital printing and modular hybrid assembly.

-

Enhanced Reliability: Flexible interconnects absorb mechanical stress, extending device lifespans under bending and flexing.

SWOT Analysis

Strengths:

-

Unique blend of rigidity and flexibility for high-performance electronics.

-

Broad application range across industries.

-

Growing manufacturing ecosystem and standardization efforts.

Weaknesses:

-

High upfront equipment and material costs.

-

Complexity in hybrid assembly yields.

-

Thermal and moisture barrier challenges on flexible substrates.

Opportunities:

-

Expansion in 5G-enabled IoT and edge computing devices.

-

Growth of wearable medical devices and personalized healthcare monitoring.

-

Development of green, biodegradable FHE components.

Threats:

-

Competition from emerging flexible monolithic semiconductors (e.g., organic ICs).

-

Rapid evolution of alternative electronics technologies (e.g., micro-LEDs).

-

Supply-chain disruptions for specialty inks and films.

Market Key Trends

-

Hybrid 3D Printing: Combining additive electronics deposition with pick-and-place for complex 3D FHE assemblies.

-

Edge AI Integration: Embedding tiny neural-network accelerators on flexible substrates for on-site data processing.

-

Self-Healing Materials: Research into inks and substrates that can repair micro-cracks under bending stress.

-

High-Resolution Printing: Advances in digital inkjet and aerosol printing achieving sub-10 µm feature sizes.

-

Regulatory Roadmaps: Development of ISO guidelines for FHE reliability testing and environmental compliance.

Covid-19 Impact

The pandemic highlighted the value of low-contact, conformable devices—such as wearable health patches for remote patient monitoring—propelling FHE development in telemedicine. Supply-chain disruptions temporarily slowed production of specialty inks and films, but concurrent stimulus funding for smart medical devices accelerated pilot production lines. Overall, COVID-19 reinforced the strategic importance of FHE in healthcare and supply-chain resilience.

Key Industry Developments

-

DuPont and PragmatIC launched a co-development program for flexible RFID-enabled smart labels in 2023.

-

FlexEnable secured investment to scale its organic TFT manufacturing for foldable displays and sensor arrays.

-

Nano Dimension unveiled DragonFly 3D printer capable of depositing conductive traces and embedding ICs on polymer substrates.

-

Henkel and E Ink introduced a fully printed, low-power e-paper display module integrating FHE touch sensors.

Analyst Suggestions

-

Invest in Integrated Supply Chains: Co-locate ink, substrate, and hybrid assembly capabilities to reduce lead times and enhance yield control.

-

Standardize Testing Protocols: Engage with industry consortia to establish reliability benchmarks under bending, temperature cycling, and humidity.

-

Focus on High-Value Niches: Target medical and defense applications with stringent performance requirements and higher margins.

-

Leverage Digital Twins: Use simulation tools to predict mechanical and thermal behavior of FHE designs before fabrication.

-

Build Cross-Industry Collaborations: Partner with textile, automotive, and packaging leaders to co-create novel FHE use cases.

Future Outlook

The FHE market is set to grow substantially through 2030, driven by convergence of miniaturization, IoT proliferation, and material science breakthroughs. As production costs decline and reliability improves, FHE will transition from niche applications to mainstream electronics, enabling new device categories that blend seamlessly into everyday objects. Continuous innovation in materials, processes, and design tools will cement FHE’s role as a foundational platform for the next generation of connected, intelligent, and form-factor-agnostic electronics.

Conclusion

Flexible Hybrid Electronics represent a paradigm shift in how electronic systems are designed, manufactured, and integrated into products. By combining the performance of rigid ICs with the versatility of printed substrates, FHE unlocks unprecedented opportunities across healthcare, automotive, consumer, and industrial sectors. Stakeholders who invest in ecosystem development, standardization, and targeted high-value applications will lead the market’s evolution toward a future where electronics conform to any shape, surface, or use case.