444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The extruders market is witnessing significant growth due to the increasing demand for extrusion processes across various industries. Extruders are widely used in the plastics, food and beverage, pharmaceutical, and construction sectors, among others. They play a crucial role in shaping and forming materials into desired shapes, resulting in efficient manufacturing processes. This comprehensive article will provide valuable insights into the extruders market, including market dynamics, regional analysis, competitive landscape, key trends, the impact of COVID-19, industry developments, analyst suggestions, future outlook, and a concluding summary.

Extruders are machines designed to process and shape raw materials by forcing them through a die to obtain a continuous profile. This process is known as extrusion. Extruders are utilized for various applications, such as plastic sheet and film production, pipe manufacturing, compounding, and 3D printing filament production. The versatility and efficiency of extruders have made them a vital tool in the manufacturing industry.

Executive Summary:

The extruders market has been witnessing steady growth in recent years, driven by increasing industrialization, technological advancements, and the demand for cost-effective manufacturing processes. The market is highly competitive, with several key players offering a wide range of extruder machines to cater to different industry requirements. However, certain challenges, such as high maintenance costs and stringent regulations, may hinder market growth. Nevertheless, the market presents significant opportunities for innovation and expansion.

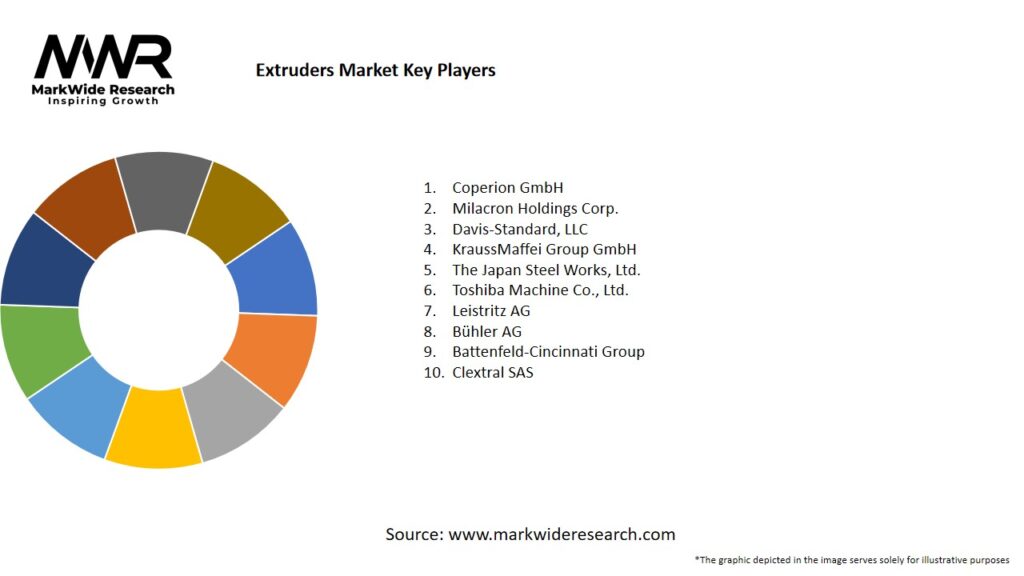

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Growth in Packaging: Flexible and rigid packaging segments account for over 40% of extruder installations, with co-extrusion equipment gaining share.

Regional Manufacturing: Asia-Pacific leads in volume demand, driven by China and India’s plastics and food-processing industries, while North America focuses on high-performance, specialty extruders.

Food Extrusion: Snack food and pet food production using twin-screw extruders is growing at a CAGR of ~6%, propelled by consumer preference for convenience and high-protein formulations.

Energy Efficiency: New extrusion lines featuring servo-driven motors and barrel insulation can reduce energy consumption by up to 15%.

Automation & Industry 4.0: Integration of process monitoring, predictive maintenance, and digital twins enhances yield, traceability, and reduces waste.

Market Drivers

Packaging Demand: Growth in flexible films, medical tubing, and cable insulation requires versatile extruder platforms.

Automotive Lightweighting: High-volume production of polymer profiles and foamed components for electric vehicles.

Food Innovation: Rising consumption of extruded snacks, breakfast cereals, and pet foods drives twin-screw extruder investments.

Sustainability Regulations: Pressure to incorporate recycled plastics and biodegradable materials necessitates extruders capable of handling varied feedstocks.

Technological Advancements: Rapid-change tooling, advanced screw geometries, and intelligent controls improve process flexibility and quality.

Market Restraints

High Capital Expenditure: Advanced twin-screw extruders can cost significantly more than presses or injection units, deterring small processors.

Technical Complexity: Skilled operators and maintenance personnel are required to manage multi-zone heating and precise screw configurations.

Feedstock Variability: Fluctuating quality of recycled materials can cause inconsistent extrusion performance and product defects.

Downtime for Changeovers: Frequent product changes require time-consuming die and screw swaps if quick-change systems are not in place.

Environmental Concerns: Emissions and noise regulations may impose additional equipment or containment costs.

Market Opportunities

Recycling Integration: On-line compounding and devolatilizing extruders for converting post-consumer plastics into high-value products.

Pharmaceutical Hot-Melt Extrusion: Expanding use for controlled-release drug formulations and personalized medicine.

3D Printing Filament Production: Small-scale extruders tailored for high-precision polymer filament manufacturing.

Foam Extrusion: Lightweight structural panels and insulation applications demand specialized foam extruders.

Co-Extrusion Growth: Multilayer barrier films for food packaging and medical applications open high-margin equipment segments.

Market Dynamics

Consolidation Among OEMs: Strategic mergers are combining extrusion technology portfolios and strengthening global distribution networks.

Digital Service Models: Predictive maintenance subscriptions and remote assistance services are emerging revenue streams.

Customization & Modular Design: Customers demand plug-and-play extruder modules to expand or reconfigure lines rapidly.

Localized Manufacturing: Reshoring trends in Europe and North America create demand for midsize extruders in regional markets.

Circular Economy Focus: Equipment designed to process mixed and reclaimed feedstocks supports sustainability goals.

Regional Analysis

Asia-Pacific: Lead region by volume, fueled by large-scale plastics compounding and food-processing plants in China and India.

North America: Demand for high-tech extruders in pharmaceuticals, medical devices, and specialty polymers.

Europe: Focus on energy-efficient machine designs and recycling-ready lines, supported by strict environmental standards.

Latin America: Emerging market for flexible packaging and cable extrusion, with investments in mid-capacity extruders.

Middle East & Africa: Growth tied to petrochemical expansions, with opportunities in PVC pipe and profile extrusion.

Competitive Landscape:

Leading Companies in the Extruders Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

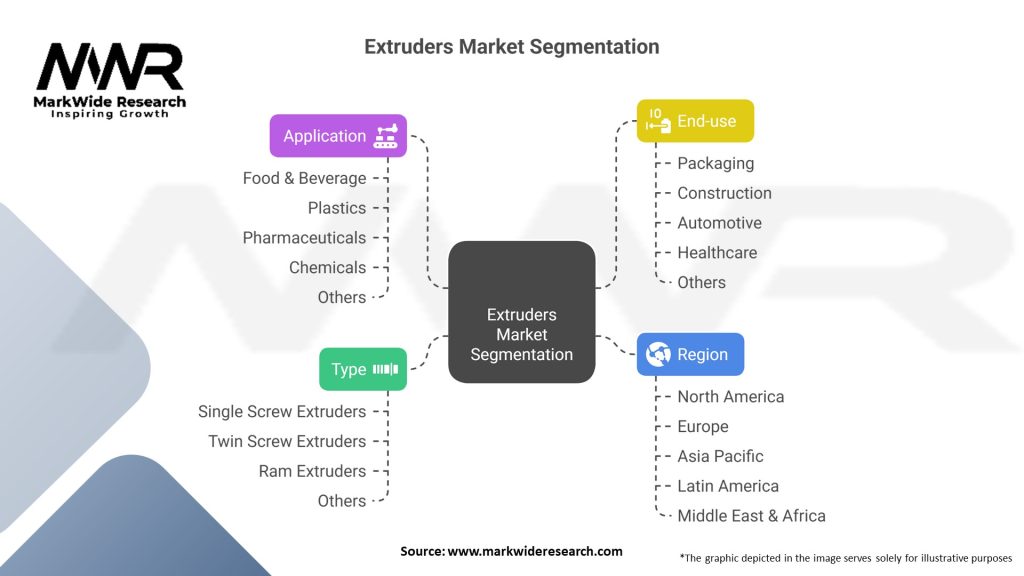

Segmentation:

The extruders market can be segmented based on machine type, application, and end-user industry. Machine type segmentation includes single-screw extruders, twin-screw extruders, and ram extruders. Application segmentation comprises plastic extrusion, food processing, pharmaceuticals, and others. End-user industry segmentation includes plastics, food and beverage, construction, healthcare, and others.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends:

Covid-19 Impact:

The COVID-19 pandemic has had a mixed impact on the extruders market. While certain industries, such as packaging and medical, witnessed increased demand for extrusion processes, others, such as automotive and construction, experienced a temporary slowdown. Supply chain disruptions, labor shortages, and economic uncertainties have affected market growth. However, the market has shown resilience and is expected to recover gradually as global economies stabilize and industrial activities resume.

Key Industry Developments:

Coperion’s Ölflex Series Launch: In 2023, introduced energy-optimized twin-screw extruders with 20% lower power draw.

Bühler’s High-Protein Extrusion Line: Debuted a modular food-extrusion system in 2024, enabling plant-based meat analog production.

Davis-Standard Digital Extrusion Suite: Rolled out cloud-based process monitoring and remote troubleshooting across its global installed base in 2022.

Leistritz Retrofit Program: Offers on-site modernization of legacy extruders with new screw elements and control upgrades to extend machine life.

Analyst Suggestions:

Future Outlook:

The extruders market is expected to witness steady growth in the coming years, driven by increasing demand for plastic products, technological advancements, and the growing focus on sustainable manufacturing practices. The adoption of automation and industry 4.0 concepts will further optimize extrusion processes and improve efficiency. Emerging economies and new applications, such as 3D printing and bio-based materials, present significant growth opportunities. However, market players need to address challenges related to high maintenance costs, stringent regulations, and the availability of skilled labor to capitalize on the market’s potential.

Conclusion:

The extruders market plays a vital role in shaping and forming materials across various industries. Technological advancements, increasing demand for plastic products, and the focus on sustainable manufacturing practices drive market growth. While the market presents opportunities for innovation and expansion, challenges such as high maintenance costs and stringent regulations need to be addressed. The industry’s future outlook is promising, with steady growth expected, especially in emerging economies and niche applications. Market players should focus on research and development, customer satisfaction, and training programs to stay competitive in this dynamic market.

What are extruders?

Extruders are machines used to process and shape materials, typically plastics, by forcing them through a die. They are essential in manufacturing processes for creating products like pipes, sheets, and films.

Who are the key players in the Extruders Market?

Key players in the Extruders Market include companies like KraussMaffei, Coperion, and Milacron, which are known for their advanced extrusion technologies and equipment, among others.

What are the main drivers of growth in the Extruders Market?

The growth of the Extruders Market is driven by increasing demand for plastic products in various industries, advancements in extrusion technology, and the rising focus on sustainable manufacturing practices.

What challenges does the Extruders Market face?

The Extruders Market faces challenges such as fluctuating raw material prices, stringent environmental regulations, and the need for continuous innovation to meet changing consumer demands.

What opportunities exist in the Extruders Market for future growth?

Opportunities in the Extruders Market include the development of bio-based and recycled materials, expansion into emerging markets, and the integration of automation and smart technologies in extrusion processes.

What trends are shaping the Extruders Market?

Trends in the Extruders Market include the increasing adoption of energy-efficient extruders, the rise of multi-layer extrusion technologies, and a growing emphasis on customization and flexibility in production processes.

Extruders Market

| Segmentation Details | Description |

|---|---|

| Type | Single Screw Extruders, Twin Screw Extruders, Ram Extruders, Others |

| Application | Food & Beverage, Plastics, Pharmaceuticals, Chemicals, Others |

| End-use | Packaging, Construction, Automotive, Healthcare, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Extruders Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at