444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Europe Radiation-Hardened Electronics Market refers to the market for electronic components and systems that are designed to withstand and operate in high-radiation environments. These environments can include space missions, nuclear power plants, medical facilities using radiation-based treatments, and defense applications. Radiation-hardened electronics are specifically engineered to withstand the detrimental effects of ionizing radiation, such as cosmic rays and gamma radiation, which can cause disruptions or damage to conventional electronic components.

Meaning

Radiation-hardened electronics are crucial for various industries that operate in high-radiation environments. These components and systems ensure the reliability and performance of electronic devices, even in the presence of intense radiation. By employing specialized materials, designs, and manufacturing processes, radiation-hardened electronics offer enhanced resistance to radiation-induced effects such as single-event upsets (SEUs), latch-up, and total ionizing dose (TID) effects.

Executive Summary

The Europe Radiation-Hardened Electronics Market is witnessing significant growth due to the increasing demand for reliable electronic components in critical applications. The market is driven by advancements in space exploration and satellite technology, the expansion of nuclear power generation, and the growing need for radiation-hardened electronics in defense and aerospace applications.

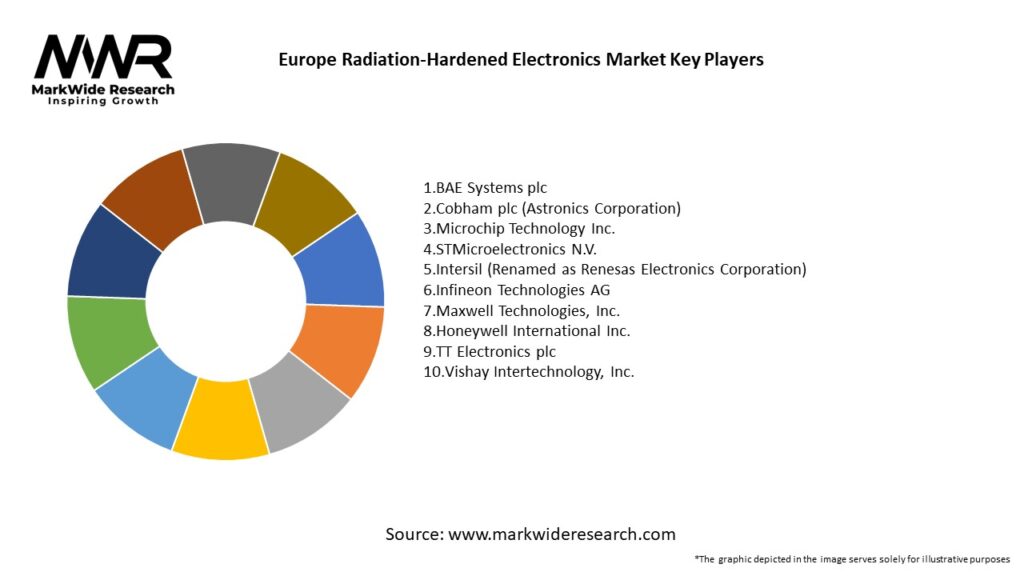

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Europe Radiation-Hardened Electronics Market is characterized by intense competition among key market players. These players focus on research and development activities to introduce innovative products and gain a competitive edge. The market dynamics are influenced by technological advancements, government regulations, industry standards, and strategic partnerships.

Regional Analysis

The Europe Radiation-Hardened Electronics Market is segmented into several key regions, including Western Europe and Eastern Europe. Western Europe, comprising countries such as Germany, France, and the United Kingdom, holds a significant market share due to its well-established aerospace, defense, and nuclear power industries. Eastern Europe, including countries like Russia and Poland, is also witnessing growth in the radiation-hardened electronics market, driven by increasing defense expenditures and space exploration initiatives.

Competitive Landscape

Leading companies in the Europe Radiation-Hardened Electronics Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

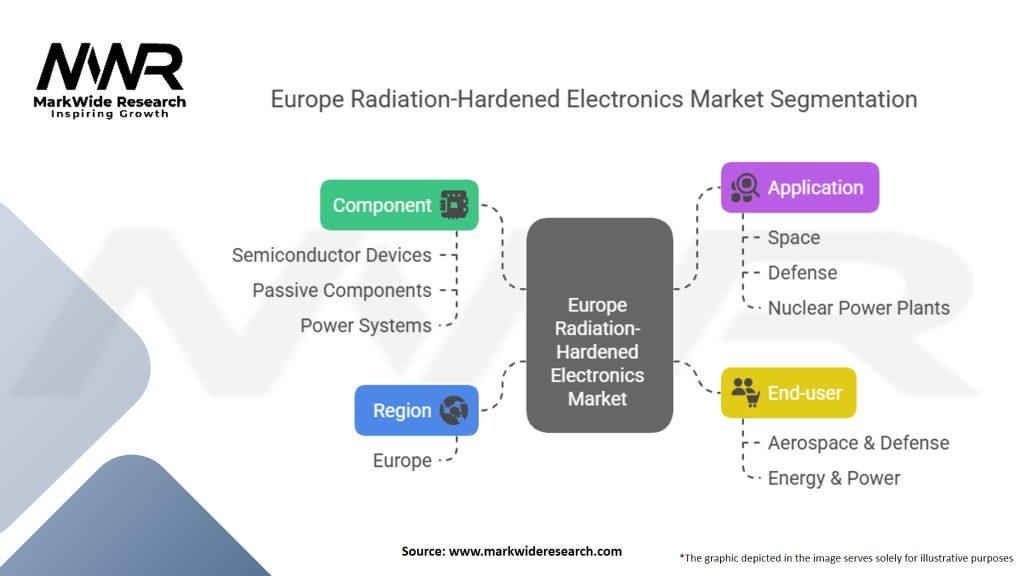

Segmentation

The Europe Radiation-Hardened Electronics Market can be segmented based on component type, manufacturing technique, application, and end-user industry.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

The SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis for the Europe Radiation-Hardened Electronics Market is as follows:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the Europe Radiation-Hardened Electronics Market. While the pandemic disrupted global supply chains and caused delays in manufacturing and distribution, it also highlighted the importance of reliable electronic components in critical sectors such as healthcare and communications. The increased reliance on remote communication and the need for robust medical equipment created opportunities for the radiation-hardened electronics market. However, the market also faced challenges due to budget constraints and reduced investments in aerospace and defense sectors during the pandemic.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the Europe Radiation-Hardened Electronics Market appears promising. With increasing investments in space exploration, growing demand for reliable defense systems, and the expansion of nuclear power generation, the market is expected to witness steady growth. Technological advancements, such as the integration of AI and ML, miniaturization, and advanced materials, will further enhance the performance and capabilities of radiation-hardened electronics. Strategic collaborations and partnerships will play a crucial role in driving innovation and meeting the evolving needs of diverse industries.

Conclusion

The Europe Radiation-Hardened Electronics Market is witnessing significant growth driven by the demand for reliable electronic components in high-radiation environments. The market offers numerous opportunities in sectors such as space exploration, defense, nuclear power, and healthcare. While challenges such as high development costs and limited commercial applications exist, advancements in technology, collaborations, and strategic investments are paving the way for a robust future. As the market continues to evolve, industry participants should focus on innovation, cost reduction, and expansion into emerging industries to capitalize on the growing demand for radiation-hardened electronics in Europe.

What are radiation-hardened electronics in the context of Europe?

Radiation-hardened electronics are specially designed components that can withstand high levels of radiation, making them essential for applications in space, nuclear power, and military environments in Europe.

Who are the key players in the Europe Radiation-Hardened Electronics Market?

Key players in the Europe Radiation-Hardened Electronics Market include companies like Airbus, BAE Systems, and Thales, among others.

What are the main drivers of growth in the Europe Radiation-Hardened Electronics Market?

The growth of the Europe Radiation-Hardened Electronics Market is driven by increasing demand for satellite technology, advancements in space exploration, and the need for reliable electronics in harsh environments.

What challenges does the Europe Radiation-Hardened Electronics Market face?

Challenges in the Europe Radiation-Hardened Electronics Market include high manufacturing costs, limited availability of raw materials, and the complexity of designing components that meet stringent radiation standards.

What future opportunities exist in the Europe Radiation-Hardened Electronics Market?

Future opportunities in the Europe Radiation-Hardened Electronics Market include the expansion of commercial space missions, the development of new technologies for radiation detection, and increased investment in defense systems.

What trends are shaping the Europe Radiation-Hardened Electronics Market?

Trends in the Europe Radiation-Hardened Electronics Market include the integration of advanced materials for better performance, the rise of miniaturization in electronic components, and a growing focus on sustainability in manufacturing processes.

Europe Radiation-Hardened Electronics Market

| Segmentation | Details |

|---|---|

| Component | Semiconductor Devices, Passive Components, Power Systems, Others |

| Application | Space, Defense, Nuclear Power Plants, Others |

| End-user | Aerospace & Defense, Energy & Power, Others |

| Region | Europe |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Europe Radiation-Hardened Electronics Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at