444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Europe pharmaceutical contract manufacturing market refers to the outsourcing of pharmaceutical manufacturing activities to third-party organizations. This market plays a crucial role in the pharmaceutical industry by providing cost-effective solutions for drug production, allowing pharmaceutical companies to focus on research and development, marketing, and distribution. The market is experiencing significant growth due to various factors, including the increasing demand for generic drugs, technological advancements, and the need for efficient supply chain management.

Meaning

Pharmaceutical contract manufacturing involves engaging external companies to handle various stages of the drug manufacturing process, including formulation, production, packaging, and labeling. Contract manufacturers possess specialized facilities, equipment, and expertise necessary for pharmaceutical production, ensuring compliance with regulatory standards and maintaining high-quality standards.

Executive Summary

The Europe pharmaceutical contract manufacturing market is witnessing steady growth, driven by the rising demand for pharmaceutical products, the need for cost optimization, and the increasing complexity of drug development and manufacturing processes. Contract manufacturing enables pharmaceutical companies to minimize capital investments, improve operational efficiency, and access advanced technologies, thereby enhancing their overall competitiveness in the market.

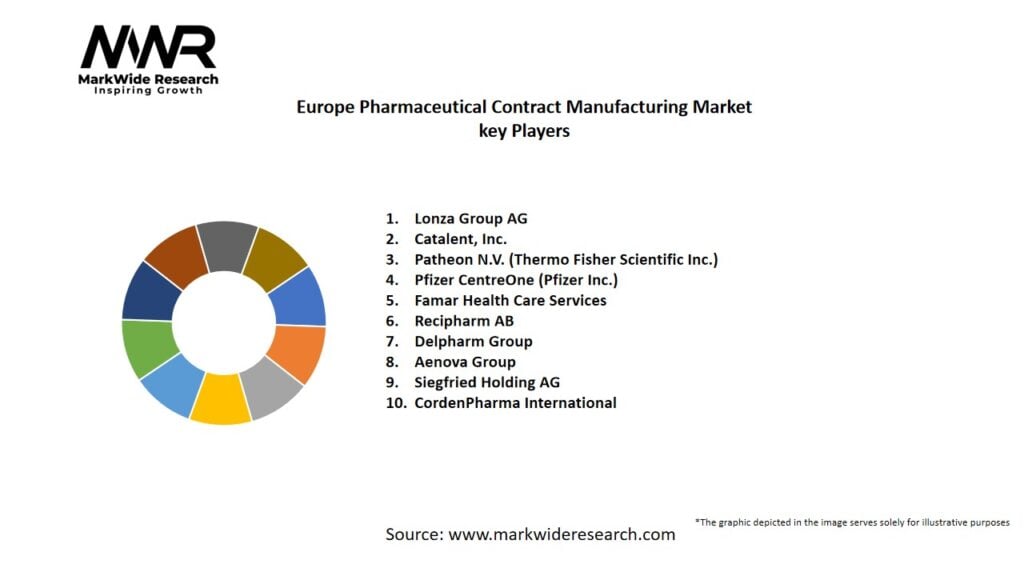

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

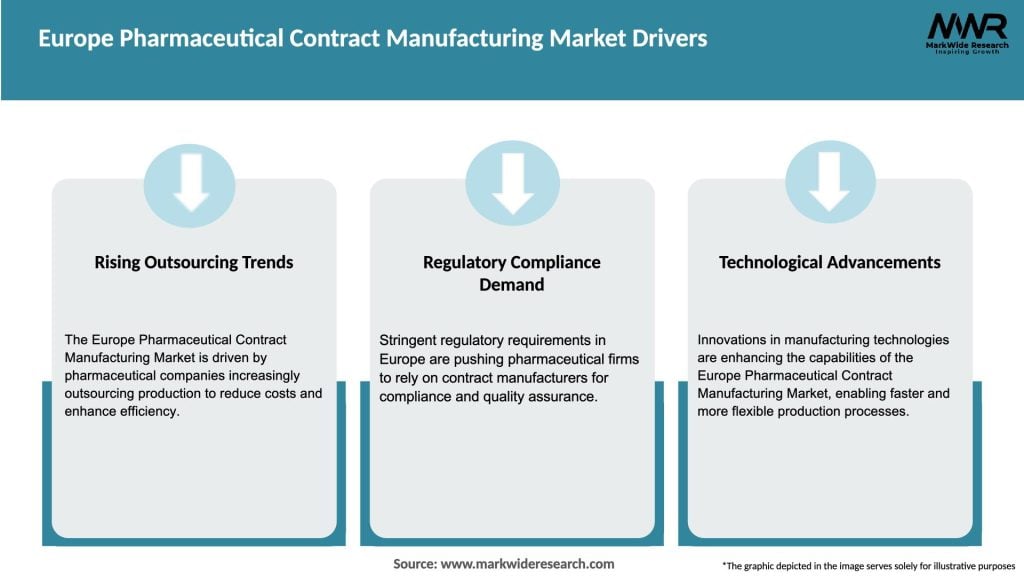

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Europe pharmaceutical contract manufacturing market is characterized by intense competition among contract manufacturing organizations. CMOs are continually striving to differentiate themselves by offering value-added services, investing in advanced technologies, and expanding their manufacturing capacities. The market dynamics are influenced by factors such as pricing pressures, regulatory changes, technological advancements, and strategic collaborations.

Regional Analysis

The Europe pharmaceutical contract manufacturing market is geographically diverse, with key players operating in countries such as Germany, Switzerland, Italy, France, and the United Kingdom. These countries have well-established pharmaceutical industries, robust regulatory frameworks, and advanced manufacturing capabilities, making them attractive destinations for contract manufacturing.

Competitive Landscape

Leading Companies in Europe Pharmaceutical Contract Manufacturing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

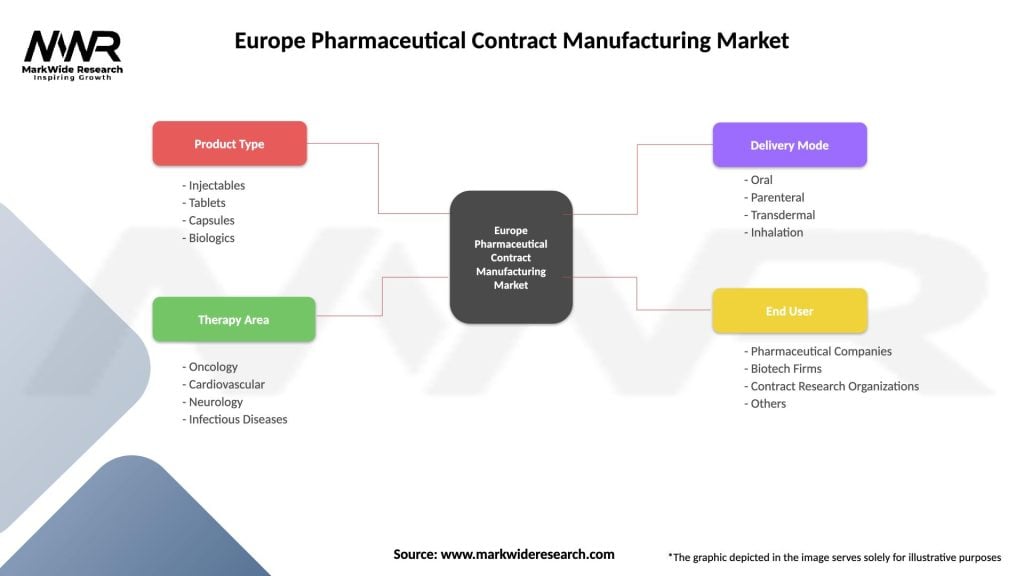

Segmentation

The market can be segmented based on various factors, including service type (formulation, production, packaging, labeling), end-user (pharmaceutical companies, biotechnology companies), and therapeutic area (oncology, cardiovascular diseases, infectious diseases, etc.). This segmentation allows for a better understanding of the market dynamics and specific requirements of different customer segments.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

COVID-19 Impact

The COVID-19 pandemic had a significant impact on the pharmaceutical industry, including contract manufacturing. The pandemic led to increased demand for essential drugs, vaccines, and medical supplies, putting pressure on contract manufacturers to ramp up production capacities. It also highlighted the need for agile and adaptable manufacturing processes to respond to unforeseen events and supply chain disruptions.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Europe pharmaceutical contract manufacturing market is poised for significant growth in the coming years. Factors such as the increasing demand for generic drugs, technological advancements, and the need for efficient supply chain management will continue to drive market expansion. Contract manufacturers that can offer specialized expertise, advanced technologies, and customized services will have a competitive edge in this evolving market.

Conclusion

The Europe pharmaceutical contract manufacturing market is a vital component of the pharmaceutical industry, enabling companies to optimize costs, focus on core competencies, and access specialized expertise. It is driven by factors such as the demand for generic drugs, technological advancements, and the need for efficient supply chain management. While facing challenges related to intellectual property, quality control, and supply chain complexity, the market offers opportunities in biologics manufacturing, emerging markets, and customized services. Contract manufacturers need to embrace advanced technologies, prioritize regulatory compliance, and enhance supply chain resilience to thrive in this competitive landscape. With a promising future outlook, the market will continue to evolve and play a crucial role in the pharmaceutical industry.

What is Pharmaceutical Contract Manufacturing?

Pharmaceutical Contract Manufacturing refers to the outsourcing of pharmaceutical production processes to third-party companies. This includes the manufacturing of active pharmaceutical ingredients (APIs), formulation development, and packaging services.

What are the key players in the Europe Pharmaceutical Contract Manufacturing Market?

Key players in the Europe Pharmaceutical Contract Manufacturing Market include Lonza Group, Recipharm, and Catalent, among others. These companies provide a range of services from drug development to commercial manufacturing.

What are the main drivers of growth in the Europe Pharmaceutical Contract Manufacturing Market?

The main drivers of growth in the Europe Pharmaceutical Contract Manufacturing Market include the increasing demand for cost-effective manufacturing solutions, the rise in biopharmaceutical production, and the need for specialized manufacturing capabilities.

What challenges does the Europe Pharmaceutical Contract Manufacturing Market face?

Challenges in the Europe Pharmaceutical Contract Manufacturing Market include regulatory compliance issues, the complexity of manufacturing processes, and the need for high-quality standards to meet stringent safety requirements.

What opportunities exist in the Europe Pharmaceutical Contract Manufacturing Market?

Opportunities in the Europe Pharmaceutical Contract Manufacturing Market include the growing trend of personalized medicine, advancements in biomanufacturing technologies, and the expansion of contract services to emerging markets.

What trends are shaping the Europe Pharmaceutical Contract Manufacturing Market?

Trends shaping the Europe Pharmaceutical Contract Manufacturing Market include the increasing adoption of automation and digital technologies, a focus on sustainability in manufacturing processes, and the rise of partnerships between pharmaceutical companies and contract manufacturers.

Europe Pharmaceutical Contract Manufacturing Market

| Segmentation Details | Description |

|---|---|

| Product Type | Injectables, Tablets, Capsules, Biologics |

| Therapy Area | Oncology, Cardiovascular, Neurology, Infectious Diseases |

| Delivery Mode | Oral, Parenteral, Transdermal, Inhalation |

| End User | Pharmaceutical Companies, Biotech Firms, Contract Research Organizations, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Europe Pharmaceutical Contract Manufacturing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at