444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Europe Molded Pulp Packaging market is experiencing significant growth due to its eco-friendly and sustainable characteristics. Molded pulp packaging refers to a type of packaging material made from recycled paper and cardboard waste, which is molded into various shapes and forms. This packaging solution has gained immense popularity in recent years, primarily driven by the increasing consumer demand for sustainable packaging options and the growing awareness of environmental concerns.

Meaning

Molded pulp packaging is a versatile and sustainable packaging solution that provides excellent protection to products during storage and transportation. It is created by mixing waste paper or cardboard with water to form a pulp, which is then molded into specific shapes using molds or dies. This process allows the packaging to be customized according to the shape and size requirements of different products. Molded pulp packaging is widely used in various industries, including electronics, food and beverage, healthcare, automotive, and consumer goods.

Executive Summary

The Europe Molded Pulp Packaging market is witnessing significant growth, driven by the increasing demand for sustainable packaging solutions and the implementation of strict environmental regulations. The market is characterized by the presence of several key players offering a wide range of molded pulp packaging products. These companies are focusing on product innovation, expansion of production capacities, and strategic collaborations to gain a competitive edge in the market.

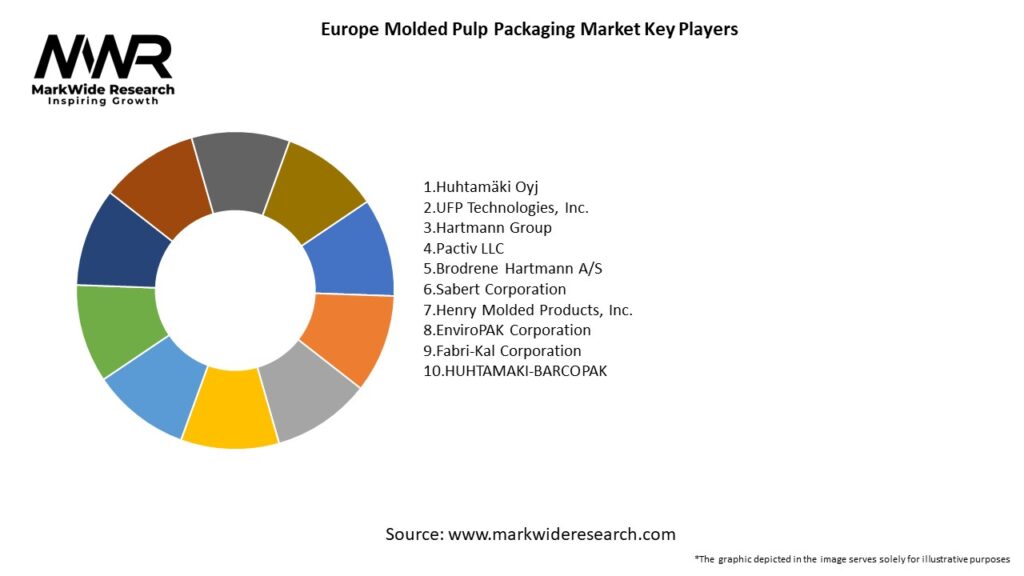

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

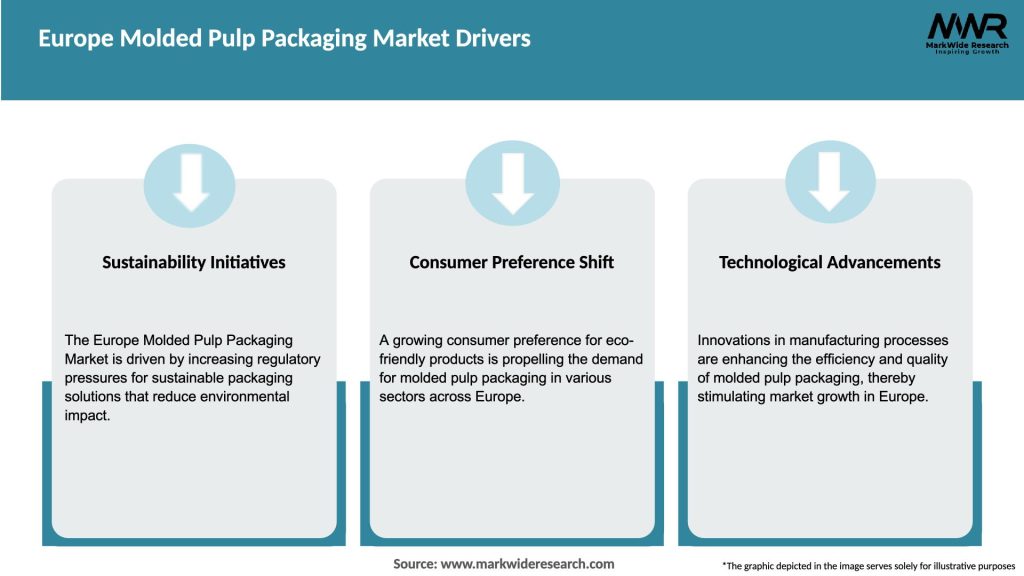

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Europe Molded Pulp Packaging market is driven by several key dynamics, including consumer demand for sustainable packaging, government regulations, industry collaborations, and advancements in manufacturing techniques. These factors collectively shape the growth and development of the market. The market dynamics are influenced by both internal factors such as product innovation and external factors such as economic conditions and environmental concerns.

Regional Analysis

The Europe Molded Pulp Packaging market is segmented into several key regions, including Western Europe and Eastern Europe. Western Europe holds the largest market share, primarily driven by countries such as Germany, France, and the United Kingdom. These countries have witnessed a significant shift towards sustainable packaging solutions, leading to increased adoption of molded pulp packaging. Eastern European countries are also experiencing steady growth in the market, driven by rising consumer awareness and the implementation of environmental regulations.

Competitive Landscape

Leading Companies in the Europe Molded Pulp Packaging Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Europe Molded Pulp Packaging market can be segmented based on product type, end-use industry, and geography.

By Product Type:

By End-Use Industry:

By Geography:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The Europe Molded Pulp Packaging market offers several key benefits for industry participants and stakeholders, including:

SWOT Analysis

The SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis of the Europe Molded Pulp Packaging market is as follows:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had both positive and negative impacts on the Europe Molded Pulp Packaging market. On the positive side, there was an increased demand for sustainable packaging solutions, including molded pulp packaging, as consumers became more conscious of health and hygiene concerns. The pandemic also highlighted the importance of resilient and eco-friendly packaging materials that can ensure product safety and reduce the risk of contamination.

However, the market also faced challenges due to disruptions in the supply chain and manufacturing operations caused by lockdowns and restrictions. The closure of various industries and reduced consumer spending affected the demand for molded pulp packaging in certain sectors. Despite the short-term setbacks, the long-term prospects for the market remain positive, driven by the increasing focus on sustainability and the adoption of eco-friendly packaging solutions.

Key Industry Developments

Analyst Suggestions

Based on the analysis of the Europe Molded Pulp Packaging market, the following suggestions are put forth for industry participants:

Future Outlook

The future outlook for the Europe Molded Pulp Packaging market is promising. The market is expected to witness steady growth driven by factors such as the increasing demand for sustainable packaging solutions, stringent environmental regulations, and the shift towards a circular economy. The development of advanced manufacturing techniques and continued innovation in product design will further fuel market growth. As companies across industries recognize the benefits of molded pulp packaging, the market is likely to witness increased adoption and penetration in various sectors.

Conclusion

The Europe Molded Pulp Packaging market is experiencing significant growth driven by the increasing demand for sustainable packaging solutions and the implementation of strict environmental regulations. Molded pulp packaging offers several benefits, including eco-friendliness, product protection, customization options, and compliance with regulatory standards. While the market faces challenges related to durability and production costs, opportunities lie in expanding the product portfolio, collaborations, and technological advancements. The Covid-19 pandemic had mixed impacts on the market, but the long-term prospects remain positive. By focusing on innovation, sustainability, partnerships, and market diversification, industry participants can capitalize on the growing demand for molded pulp packaging and shape a successful future in the market.

What is Europe molded pulp packaging?

Europe molded pulp packaging refers to packaging products made from recycled paper and cardboard, shaped into specific forms for various applications. This sustainable packaging solution is widely used in food, electronics, and consumer goods industries due to its biodegradable properties.

Who are the key players in the Europe molded pulp packaging market?

Key players in the Europe molded pulp packaging market include Huhtamaki, Stora Enso, and UFP Technologies, among others. These companies are known for their innovative approaches and commitment to sustainability in packaging solutions.

What are the main drivers of growth in the Europe molded pulp packaging market?

The main drivers of growth in the Europe molded pulp packaging market include increasing consumer demand for sustainable packaging, stringent regulations on plastic use, and the rise of e-commerce, which requires protective packaging solutions.

What challenges does the Europe molded pulp packaging market face?

The Europe molded pulp packaging market faces challenges such as competition from alternative packaging materials, variability in raw material availability, and the need for technological advancements to improve production efficiency.

What opportunities exist in the Europe molded pulp packaging market?

Opportunities in the Europe molded pulp packaging market include the growing trend towards eco-friendly packaging solutions, potential expansion into new sectors like cosmetics and pharmaceuticals, and advancements in manufacturing technologies that enhance product quality.

What trends are shaping the Europe molded pulp packaging market?

Trends shaping the Europe molded pulp packaging market include increased investment in sustainable materials, the development of custom packaging solutions for specific products, and a shift towards circular economy practices that promote recycling and reuse.

Europe Molded Pulp Packaging Market

| Segmentation | Details |

|---|---|

| Product Type | Trays, Clamshells, Plates, Cups, Others |

| Material | Virgin Pulp, Recycled Pulp |

| End-Use Industry | Food & Beverage, Electronics, Cosmetics & Personal Care, Healthcare, Others |

| Region | Europe |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Europe Molded Pulp Packaging Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at