444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Europe metal casting market is a flourishing sector within the manufacturing industry. Metal casting refers to the process of pouring molten metal into a mold to obtain a desired shape or form. It is a critical component of various industries, including automotive, aerospace, construction, and machinery. The European metal casting market has experienced steady growth over the years, driven by the region’s robust industrial infrastructure and the demand for high-quality metal components.

Meaning

Metal casting is a manufacturing process that involves pouring molten metal into a mold cavity to create intricate shapes and structures. It is a versatile technique that allows for the production of complex parts with precise dimensions. The process begins with the selection of suitable metals, such as iron, steel, aluminum, or copper alloys. The metal is then melted in a furnace and poured into a mold, which can be made of sand, ceramic, or metal. After the metal cools and solidifies, the mold is removed, and the finished product is obtained.

Executive Summary

The Europe metal casting market has witnessed significant growth in recent years. The region is home to several established metal casting companies and has a robust supply chain network. The demand for metal castings is driven by the thriving automotive and aerospace industries, which require high-performance components. Additionally, the construction sector’s expansion and the growing emphasis on renewable energy have further contributed to the market’s growth. However, the market also faces challenges, such as increasing competition and environmental regulations.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Europe metal casting market operates in a dynamic environment influenced by various factors. The demand for metal castings is driven by end-use industries, such as automotive, aerospace, and construction. Technological advancements and sustainability initiatives play a crucial role in shaping market trends. Additionally, market dynamics are influenced by regulatory changes, raw material availability, and competitive forces. To stay competitive, companies must stay abreast of market dynamics and adapt their strategies accordingly.

Regional Analysis

The Europe metal casting market can be segmented into several regions, including Western Europe, Eastern Europe, Southern Europe, and Northern Europe. Western Europe is the largest market for metal castings, driven by countries such as Germany, France, and the United Kingdom. These countries have a strong manufacturing base and are major exporters of metal castings. Eastern Europe is also a significant market, with countries like Poland, Hungary, and the Czech Republic witnessing rapid industrial growth. Southern Europe and Northern Europe contribute to the market with their construction and automotive industries, respectively.

Competitive Landscape

Leading Companies in the Europe Metal Casting Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

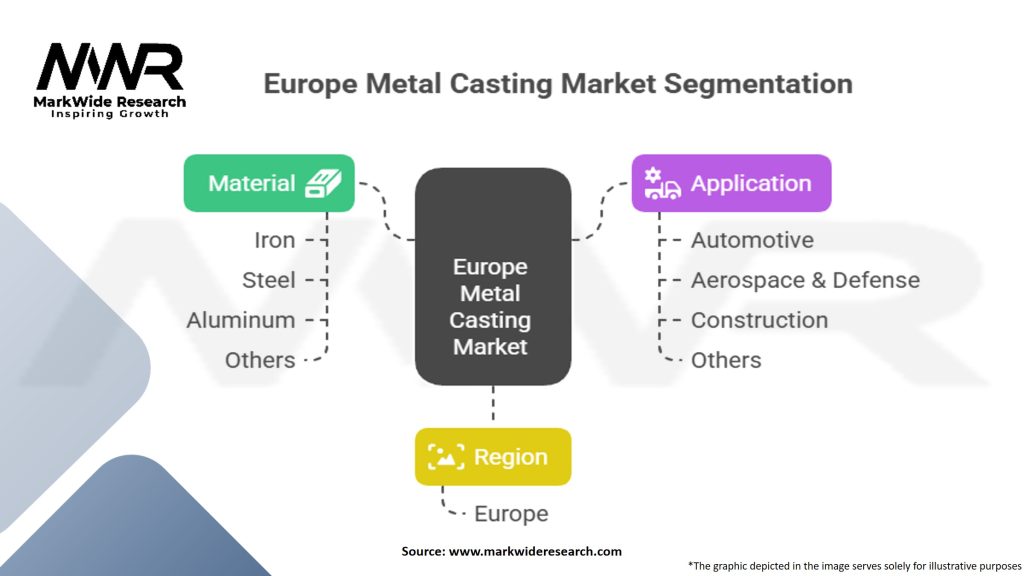

Segmentation

The Europe metal casting market can be segmented based on metal type, casting process, end-use industry, and geography. By metal type, the market includes iron, steel, aluminum, and others. Casting processes encompass sand casting, die casting, investment casting, and permanent mold casting. The end-use industries driving the market include automotive, aerospace, construction, machinery, and others. Geographically, the market is segmented into Western Europe, Eastern Europe, Southern Europe, and Northern Europe.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the Europe metal casting market. The outbreak resulted in disruptions across the supply chain, reduced demand from end-use industries, and temporary shutdowns of manufacturing facilities. The automotive and aerospace sectors, in particular, experienced a downturn, leading to a decline in metal casting orders. However, as the situation improved, the market gradually recovered, aided by government stimulus packages and the resumption of economic activities.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the Europe metal casting market appears promising, driven by the steady growth of key end-use industries and technological advancements. The demand for lightweight metal castings, driven by the automotive and aerospace sectors, is expected to increase. The expansion of renewable energy sources and the adoption of 3D printing present new opportunities for market growth. However, companies must navigate challenges such as intense competition and environmental regulations to thrive in the evolving market landscape.

Conclusion

The Europe metal casting market is experiencing steady growth, fueled by the automotive, aerospace, and construction industries. Technological advancements, such as 3D printing and automation, are transforming the industry. Sustainability and compliance with environmental regulations have become crucial considerations for metal casting companies. Despite challenges, the market offers significant opportunities for revenue generation and innovation. By staying abreast of market trends, embracing sustainability, and fostering customer relationships, companies can position themselves for success in the evolving metal casting market in Europe.

What is the Europe Metal Casting?

Europe Metal Casting refers to the process of pouring molten metal into a mold to create various components and products used in industries such as automotive, aerospace, and construction.

Who are the key players in the Europe Metal Casting Market?

Key players in the Europe Metal Casting Market include companies like Georg Fischer AG, Alcoa Corporation, and foundries such as KSM Castings Group, among others.

What are the main drivers of the Europe Metal Casting Market?

The main drivers of the Europe Metal Casting Market include the increasing demand for lightweight materials in automotive manufacturing, advancements in casting technologies, and the growth of the renewable energy sector.

What challenges does the Europe Metal Casting Market face?

The Europe Metal Casting Market faces challenges such as fluctuating raw material prices, environmental regulations, and the need for skilled labor in the casting process.

What opportunities exist in the Europe Metal Casting Market?

Opportunities in the Europe Metal Casting Market include the rising demand for electric vehicles, innovations in sustainable casting practices, and the expansion of the aerospace sector.

What trends are shaping the Europe Metal Casting Market?

Trends shaping the Europe Metal Casting Market include the adoption of additive manufacturing techniques, increased focus on recycling and sustainability, and the integration of smart technologies in production processes.

Europe Metal Casting Market:

| Segmentation | Details |

|---|---|

| Material | Iron, Steel, Aluminum, Others |

| Application | Automotive, Aerospace & Defense, Construction, Others |

| Region | Europe |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Europe Metal Casting Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at