444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview:

The Europe Demolition Robot market is witnessing a paradigm shift in the construction industry, where robotic technologies are increasingly deployed for precision, safety, and efficiency in demolition processes. Demolition robots, equipped with advanced features and capabilities, are revolutionizing the way buildings and structures are dismantled. This market overview delves into the key dynamics, trends, and challenges shaping the Europe Demolition Robot market.

Meaning:

Demolition robots are specialized machines designed for the controlled and efficient dismantling of structures. These robots are equipped with various tools and attachments, such as hydraulic breakers, crushers, and shears, enabling them to handle a wide range of demolition tasks. The deployment of demolition robots minimizes the risks associated with manual demolition, enhances worker safety, and accelerates the overall demolition process.

Executive Summary:

The Europe Demolition Robot market is experiencing robust growth, driven by the construction industry’s increasing focus on safety, environmental sustainability, and efficiency. Demolition robots offer a range of benefits, including precision in selective demolition, reduced noise and dust pollution, and improved safety for operators. This executive summary provides a snapshot of the key market trends and insights.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The Europe Demolition Robot market operates within a dynamic environment influenced by factors such as technological advancements, regulatory changes, market consolidation, and industry trends. Adapting to these dynamics is essential for manufacturers, service providers, and construction companies to stay competitive and capitalize on emerging opportunities.

Regional Analysis:

The European market for demolition robots varies across regions, with factors such as urbanization rates, construction activities, and regulatory landscapes influencing demand. Key regions in Europe, including Western Europe, Central and Eastern Europe, and the Nordic countries, exhibit distinct characteristics in the adoption of demolition robots.

Competitive Landscape:

Leading Companies in the Europe Demolition Robot Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

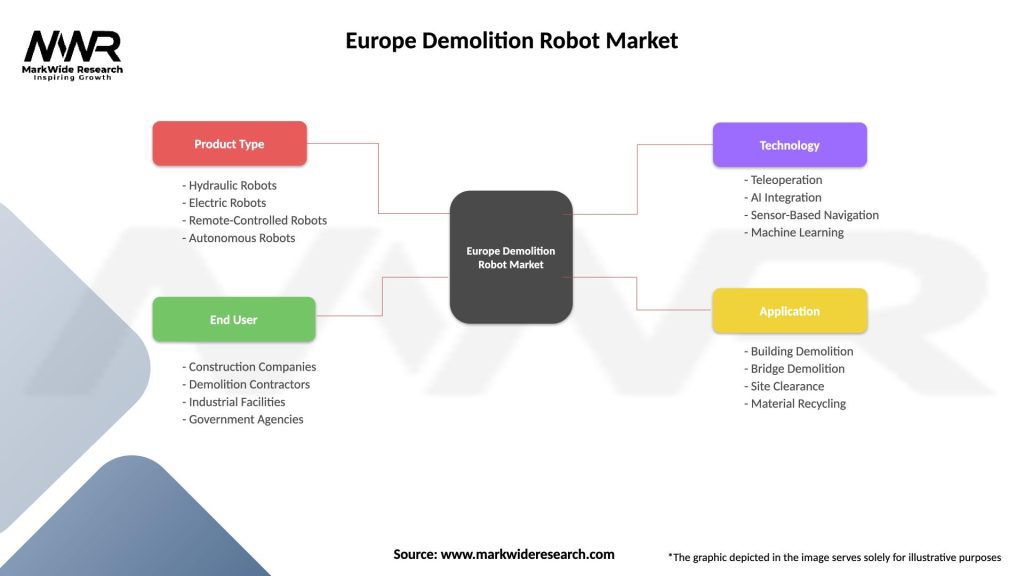

Segmentation:

The Europe Demolition Robot market can be segmented based on various factors:

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding these factors through a SWOT analysis provides insights for industry participants to capitalize on strengths, address weaknesses, explore opportunities, and mitigate potential threats.

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic had varying impacts on the Europe Demolition Robot market. While construction activities faced disruptions during lockdowns, the subsequent emphasis on safety and efficiency in construction practices accelerated the adoption of robotic technologies. The pandemic underscored the importance of technologies that minimize manual labor and enhance project resilience.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The future outlook for the Europe Demolition Robot market is optimistic, with sustained growth expected. The construction industry’s increasing recognition of the benefits offered by demolition robots, coupled with advancements in technology and collaborative efforts, will drive market expansion. The market’s ability to address challenges, embrace innovation, and cater to evolving industry needs will shape its trajectory in the coming years.

Conclusion:

The Europe Demolition Robot market is at the forefront of transforming construction practices, offering a paradigm shift in the way structures are dismantled. With a focus on safety, precision, and efficiency, demolition robots are becoming indispensable tools for the construction industry. Overcoming challenges such as high initial costs and operator training requirements will be crucial for widespread adoption. As the market continues to evolve, collaboration, innovation, and a commitment to sustainability will be key drivers of success. The integration of advanced technologies and the ongoing development of specialized solutions will position demolition robots as integral components of the modern construction toolkit, contributing to safer, more efficient, and environmentally responsible demolition practices.

What is Demolition Robot?

A demolition robot is a specialized machine designed for the safe and efficient dismantling of structures. These robots are used in various applications, including building demolition, hazardous material removal, and site clearance.

What are the key players in the Europe Demolition Robot Market?

Key players in the Europe Demolition Robot Market include Brokk AB, Husqvarna Group, and CEA S.p.A., among others. These companies are known for their innovative demolition solutions and advanced robotic technologies.

What are the main drivers of the Europe Demolition Robot Market?

The main drivers of the Europe Demolition Robot Market include the increasing demand for safety in construction sites, the need for efficient demolition processes, and the growing trend of urban redevelopment. Additionally, advancements in robotic technology are enhancing operational capabilities.

What challenges does the Europe Demolition Robot Market face?

The Europe Demolition Robot Market faces challenges such as high initial investment costs and the need for skilled operators. Furthermore, regulatory compliance and safety standards can complicate the adoption of demolition robots in certain regions.

What opportunities exist in the Europe Demolition Robot Market?

Opportunities in the Europe Demolition Robot Market include the expansion of smart city initiatives and the increasing focus on sustainable construction practices. Additionally, the integration of AI and automation in demolition processes presents significant growth potential.

What trends are shaping the Europe Demolition Robot Market?

Trends shaping the Europe Demolition Robot Market include the rise of remote-controlled and autonomous demolition robots, as well as the development of eco-friendly demolition solutions. These innovations are aimed at improving efficiency and reducing environmental impact.

Europe Demolition Robot Market

| Segmentation Details | Description |

|---|---|

| Product Type | Hydraulic Robots, Electric Robots, Remote-Controlled Robots, Autonomous Robots |

| End User | Construction Companies, Demolition Contractors, Industrial Facilities, Government Agencies |

| Technology | Teleoperation, AI Integration, Sensor-Based Navigation, Machine Learning |

| Application | Building Demolition, Bridge Demolition, Site Clearance, Material Recycling |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Europe Demolition Robot Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at