444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview:

The Europe Composite Process Material Kits market is a dynamic sector witnessing significant growth, driven by the expanding use of composite materials across industries. These kits play a crucial role in simplifying and streamlining the composite manufacturing process, providing comprehensive solutions for a wide range of applications.

Meaning:

Composite process material kits in Europe refer to packaged solutions that include a set of materials essential for composite manufacturing processes. These kits typically consist of various composite materials, resins, reinforcements, and ancillary products required for specific applications in industries such as aerospace, automotive, construction, and marine.

Executive Summary:

The Europe Composite Process Material Kits market is experiencing a surge in demand, thanks to the versatility and lightweight properties of composite materials. This executive summary encapsulates key insights, market trends, and the competitive landscape, offering stakeholders a snapshot of the market’s current state and future potential.

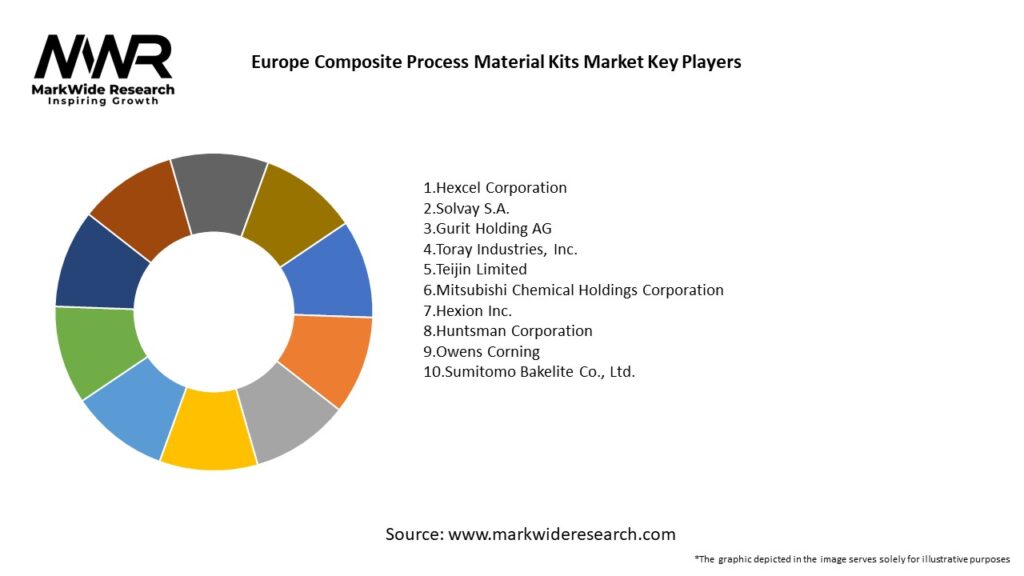

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The Europe Composite Process Material Kits market operates in a dynamic landscape influenced by factors such as technological advancements, industry collaborations, market trends, and regulatory frameworks. Understanding these dynamics is essential for market participants to make informed decisions and stay competitive.

Regional Analysis:

Competitive Landscape:

Leading Companies in the Europe Composite Process Material Kits Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation:

The market segmentation based on industry applications, types of composite materials, and end-user sectors allows for a detailed understanding of specific market segments and facilitates targeted strategies for diverse customer needs.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact:

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The Europe Composite Process Material Kits market is poised for sustained growth, driven by the increasing adoption of composite materials across industries. The future will see continued innovations, with a focus on sustainability, customization, and the integration of smart technologies in composite process material kits.

Conclusion:

The Europe Composite Process Material Kits market represents a vibrant and evolving landscape, with the adoption of composite materials playing a pivotal role in various industries. As industries seek lightweight, durable, and sustainable solutions, composite process material kits provide a streamlined approach to manufacturing processes. While facing challenges related to costs, standardization, and recycling, the market is expected to thrive through innovations, collaborative efforts, and a commitment to sustainable practices. By addressing industry-specific needs and staying adaptable to technological advancements, the market is well-positioned for a transformative future.

What is Composite Process Material Kits?

Composite Process Material Kits refer to a collection of materials and tools used in the manufacturing and processing of composite materials. These kits typically include resins, fibers, and other components necessary for creating composite structures used in various industries such as aerospace, automotive, and construction.

What are the key players in the Europe Composite Process Material Kits Market?

Key players in the Europe Composite Process Material Kits Market include Hexcel Corporation, Toray Industries, and Sika AG, among others. These companies are known for their innovative solutions and extensive product offerings in composite materials.

What are the growth factors driving the Europe Composite Process Material Kits Market?

The growth of the Europe Composite Process Material Kits Market is driven by the increasing demand for lightweight materials in the automotive and aerospace sectors. Additionally, advancements in manufacturing technologies and a growing focus on sustainability are contributing to market expansion.

What challenges does the Europe Composite Process Material Kits Market face?

The Europe Composite Process Material Kits Market faces challenges such as high production costs and the complexity of composite material processing. Additionally, the need for skilled labor and potential regulatory hurdles can hinder market growth.

What opportunities exist in the Europe Composite Process Material Kits Market?

Opportunities in the Europe Composite Process Material Kits Market include the increasing adoption of composites in renewable energy applications, such as wind turbine blades, and the growing trend of lightweighting in various industries. Furthermore, innovations in recycling technologies for composite materials present new avenues for growth.

What trends are shaping the Europe Composite Process Material Kits Market?

Trends shaping the Europe Composite Process Material Kits Market include the rise of bio-based composites and the integration of smart materials that enhance performance. Additionally, the focus on circular economy practices is influencing the development of more sustainable composite solutions.

Europe Composite Process Material Kits Market

| Segmentation Details | Description |

|---|---|

| Product Type | Prepregs, Resins, Reinforcements, Core Materials |

| Application | Aerospace, Automotive, Marine, Wind Energy |

| End User | Manufacturers, OEMs, Tier-1 Suppliers, Research Institutions |

| Distribution Channel | Direct Sales, Distributors, Online Retail, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at