444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Europe Carbon Black Market is witnessing steady growth due to increasing demand from various industries. Carbon black, a form of amorphous carbon, is widely used as a reinforcing filler in tires and other rubber products. It is also utilized in plastics, coatings, inks, and other applications. The market in Europe is characterized by the presence of several key players and a strong focus on product innovation and development.

Meaning

Carbon black is a fine black powder produced by the incomplete combustion of hydrocarbon fuels. It consists of carbon clusters that form aggregates and can be further classified based on their physical and chemical properties. The material is known for its high tinting strength, conductivity, and reinforcing properties. Carbon black is extensively used in the manufacturing of tires, as it improves their strength and durability.

Executive Summary

The Europe Carbon Black Market is expected to experience steady growth in the coming years. Factors such as the increasing demand for tires, rising industrialization, and growing automotive sector are driving the market. The market is also witnessing significant investments in research and development activities to enhance product quality and meet the evolving customer requirements. However, the market is not without its challenges, including stringent regulations and the adverse environmental impact associated with carbon black production.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

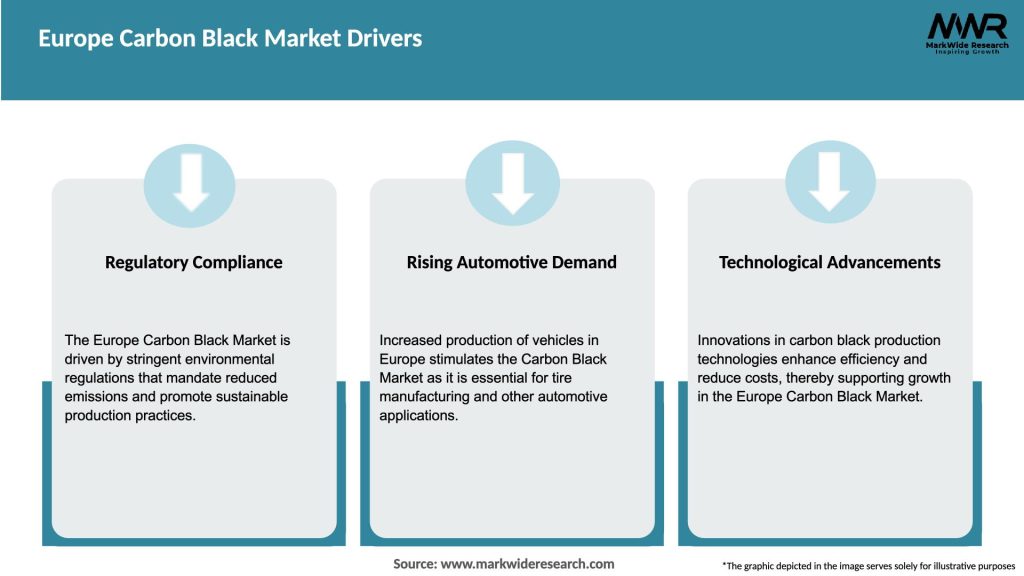

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Europe Carbon Black Market is characterized by intense competition among key players, technological advancements, and shifting consumer preferences. The market dynamics are influenced by factors such as raw material availability, regulatory frameworks, and economic conditions. Manufacturers are focusing on product innovation, expansion into new geographies, and strategic collaborations to gain a competitive edge.

Regional Analysis

Europe is a significant market for carbon black, with countries such as Germany, France, the United Kingdom, and Italy leading in terms of consumption. These countries have a well-established automotive industry, which drives the demand for carbon black. The presence of major tire manufacturers in the region also contributes to market growth. Additionally, the increasing focus on sustainability and environmental regulations in Europe is shaping the market landscape.

Competitive Landscape

Leading Companies in the Europe Carbon Black Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Europe Carbon Black Market can be segmented based on the following criteria:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the Europe Carbon Black Market. The market experienced a temporary slowdown due to disruptions in the automotive sector and reduced industrial activities during lockdowns. However, with the gradual easing of restrictions and the resumption of economic activities, the market has shown signs of recovery. The demand for tires, in particular, has rebounded as the automotive industry regained momentum. Manufacturers have implemented safety measures and adapted their operations to ensure business continuity.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Europe Carbon Black Market is expected to continue its growth trajectory in the coming years. The increasing demand from industries such as automotive, packaging, and construction, coupled with technological advancements and sustainability initiatives, will drive market expansion. However, manufacturers need to address environmental concerns, comply with stringent regulations, and invest in research and development to stay competitive in the evolving market landscape.

Conclusion

The Europe Carbon Black Market is witnessing steady growth driven by the demand from various industries. The tire industry remains a major consumer of carbon black, while other sectors such as plastics, coatings, and rubber goods also contribute to market growth. The market faces challenges related to environmental regulations and volatile raw material prices. However, opportunities lie in sustainable manufacturing practices, specialty carbon black grades, and emerging applications. With strategic investments in innovation, collaboration, and sustainability, the market is expected to thrive in the future.

What is carbon black in the context of the Europe Carbon Black Market?

Carbon black is a fine black powder made from burning hydrocarbons in insufficient air. It is primarily used as a reinforcing agent in rubber products, particularly tires, and as a pigment in plastics and coatings within the Europe Carbon Black Market.

Who are the key players in the Europe Carbon Black Market?

Key players in the Europe Carbon Black Market include Continental Carbon, Orion Engineered Carbons, and Cabot Corporation, among others.

What are the main drivers of growth in the Europe Carbon Black Market?

The growth of the Europe Carbon Black Market is driven by the increasing demand for tires in the automotive industry, the expansion of the construction sector, and the rising use of carbon black in coatings and plastics.

What challenges does the Europe Carbon Black Market face?

The Europe Carbon Black Market faces challenges such as environmental regulations regarding emissions, fluctuations in raw material prices, and competition from alternative materials.

What opportunities exist in the Europe Carbon Black Market?

Opportunities in the Europe Carbon Black Market include the development of sustainable carbon black production methods, the growing demand for high-performance materials in various industries, and advancements in recycling technologies.

What trends are shaping the Europe Carbon Black Market?

Trends in the Europe Carbon Black Market include a shift towards eco-friendly products, increased investment in research and development for innovative applications, and the rising popularity of specialty carbon blacks for specific industrial uses.

Europe Carbon Black Market

| Segmentation | Details |

|---|---|

| Process | Furnace Black, Channel Black, Acetylene Black |

| Application | Tire, Rubber Goods, Plastics, Inks |

| Region | Germany, UK, France, Italy, Spain, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Europe Carbon Black Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at