444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Europe Articulated Robot Market refers to the market for robotic systems that are designed with multiple rotary joints, allowing them to perform complex and precise movements. These robots are widely used in various industries, including automotive, electronics, healthcare, and manufacturing. With their ability to automate repetitive tasks and enhance productivity, articulated robots have gained significant popularity in the European market.

Meaning

Articulated robots are a type of industrial robots that consist of a series of joints connected by rigid links. These joints enable the robot to move in multiple axes, providing flexibility and dexterity in performing tasks. The articulated design resembles the human arm, allowing the robots to mimic human-like movements. They are equipped with sensors, actuators, and control systems to execute precise motions and interact with their environment.

Executive Summary

The Europe Articulated Robot Market has experienced substantial growth in recent years. The demand for these robots is driven by the need for automation and improved efficiency in industries across the region. Articulated robots offer advantages such as increased production speed, reduced labor costs, improved quality control, and enhanced worker safety. As a result, they have become an integral part of various manufacturing processes.

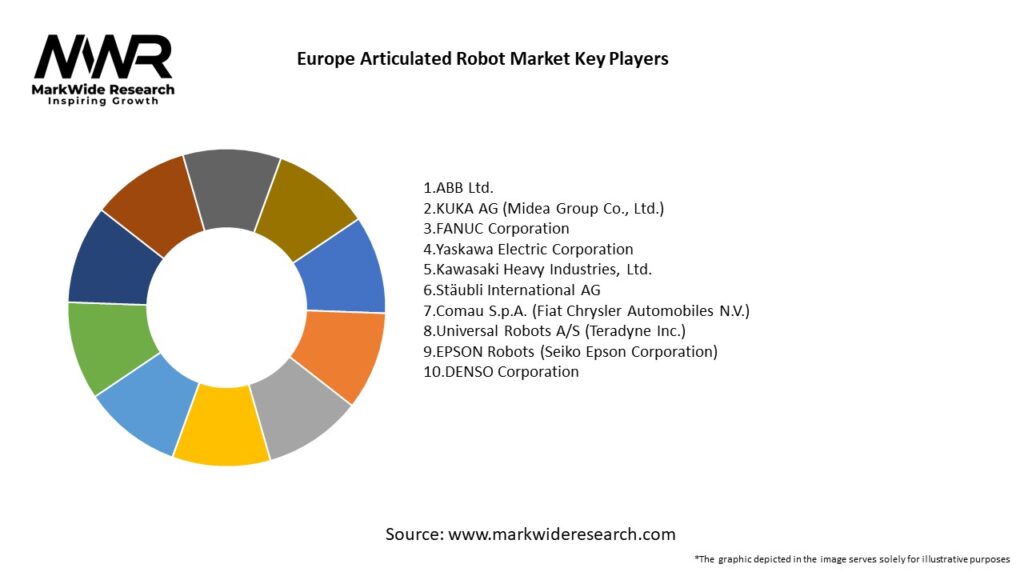

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Europe Articulated Robot Market is driven by a combination of technological advancements, industry trends, and economic factors. The market is witnessing a shift towards more advanced, intelligent, and collaborative robotic systems. The demand for articulated robots is expected to remain strong as industries continue to embrace automation, efficiency, and safety in their operations.

Regional Analysis

The European market for articulated robots is segmented into various regions, including Western Europe, Eastern Europe, and Southern Europe. Western Europe, comprising countries such as Germany, France, and the United Kingdom, holds the largest market share due to the presence of established manufacturing industries and technological advancements. Eastern Europe, including countries like Poland, Hungary, and the Czech Republic, is witnessing significant growth as industries in this region modernize and adopt advanced automation solutions.

Competitive Landscape

Leading companies in the Europe Articulated Robot Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

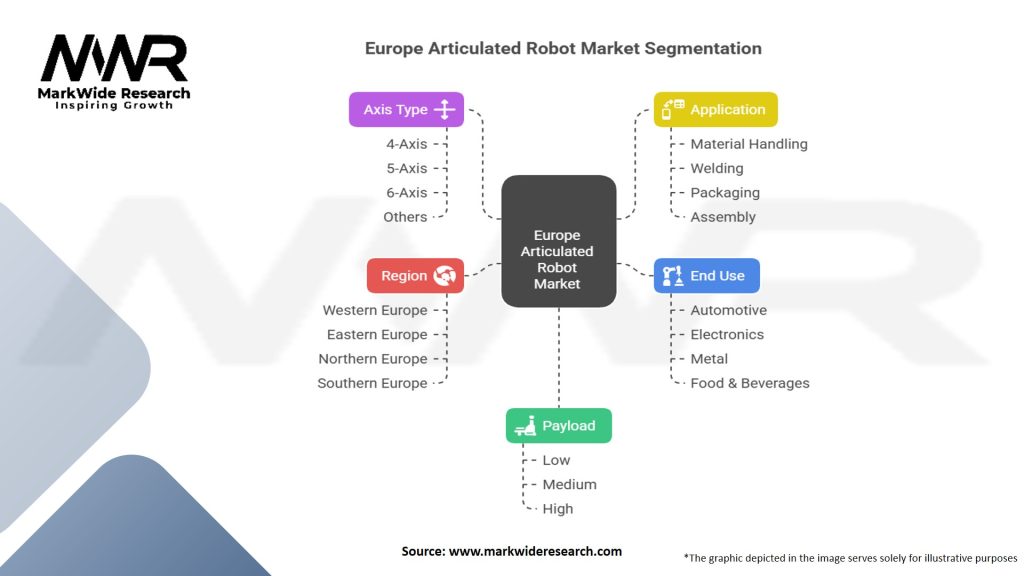

Segmentation

The Europe Articulated Robot Market can be segmented based on the application, industry vertical, and robot payload capacity. Application segments include material handling, welding and soldering, assembly, painting and dispensing, and others. The industry verticals where articulated robots find applications include automotive, electronics, healthcare, food and beverages, aerospace and defense, and others.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the Europe Articulated Robot Market. While the initial phase of the pandemic resulted in disruptions to the supply chain and manufacturing activities, it also accelerated the adoption of automation and robotics. Industries realized the importance of resilient and flexible production systems, leading to increased investments in articulated robots to mitigate the risks associated with future disruptions.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the Europe Articulated Robot Market looks promising, with sustained growth expected in the coming years. The market will be driven by the increasing adoption of automation, advancements in AI and IoT technologies, and the expansion of robotic applications into emerging industries and service sectors. The demand for articulated robots is likely to surge as industries strive for efficiency, precision, and adaptability in their operations.

Conclusion

The Europe Articulated Robot Market is witnessing significant growth driven by the need for automation, improved productivity, and enhanced worker safety. Articulated robots provide flexibility, precision, and efficiency in performing complex tasks across various industries. While there are challenges such as high initial investment and the need for skilled workforce, the market offers significant opportunities in emerging industries, IoT integration, and service robotics. Companies should focus on innovation, strategic partnerships, and customer-centric approaches to capitalize on the market’s potential and cater to evolving industry demands. The future outlook for the Europe Articulated Robot Market remains positive, with continued advancements and expanding applications on the horizon.

What is the Europe Articulated Robot?

The Europe Articulated Robot refers to a type of robotic arm that is designed with multiple joints, allowing for a wide range of motion and flexibility. These robots are commonly used in manufacturing, assembly, and material handling applications across various industries.

Who are the key players in the Europe Articulated Robot Market?

Key players in the Europe Articulated Robot Market include companies such as KUKA, ABB, and FANUC, which are known for their advanced robotic solutions. Other notable companies include Yaskawa and Universal Robots, among others.

What are the main drivers of growth in the Europe Articulated Robot Market?

The main drivers of growth in the Europe Articulated Robot Market include the increasing demand for automation in manufacturing processes, the need for precision in assembly tasks, and the rising labor costs that push companies to adopt robotic solutions.

What challenges does the Europe Articulated Robot Market face?

The Europe Articulated Robot Market faces challenges such as high initial investment costs and the complexity of integrating robots into existing production lines. Additionally, there is a skills gap in the workforce that can hinder the effective use of these technologies.

What opportunities exist in the Europe Articulated Robot Market?

Opportunities in the Europe Articulated Robot Market include the expansion of robotics into new sectors such as healthcare and logistics, as well as advancements in artificial intelligence that enhance robot capabilities. The growing trend of Industry Four Point Zero also presents significant potential for growth.

What trends are shaping the Europe Articulated Robot Market?

Trends shaping the Europe Articulated Robot Market include the increasing adoption of collaborative robots that work alongside humans, advancements in sensor technology for improved precision, and the integration of IoT for real-time monitoring and data analysis.

Europe Articulated Robot Market Segmentations

| Segment | Details |

|---|---|

| Payload | Low, Medium, High |

| Axis Type | 4-Axis, 5-Axis, 6-Axis, Others |

| Application | Material Handling, Welding, Packaging, Assembly |

| End Use | Automotive, Electronics, Metal, Food & Beverages |

| Region | Western Europe, Eastern Europe, Northern Europe, Southern Europe |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Europe Articulated Robot Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at