The engine driven welders market has witnessed robust growth due to the rising demand for efficient and portable welding solutions. These welders offer the flexibility to operate in areas with limited or no access to electrical power, making them indispensable for industries such as construction, oil and gas, and mining. Moreover, advancements in engine technology and welding processes have enhanced the efficiency and performance of these machines, further driving their adoption across various sectors.

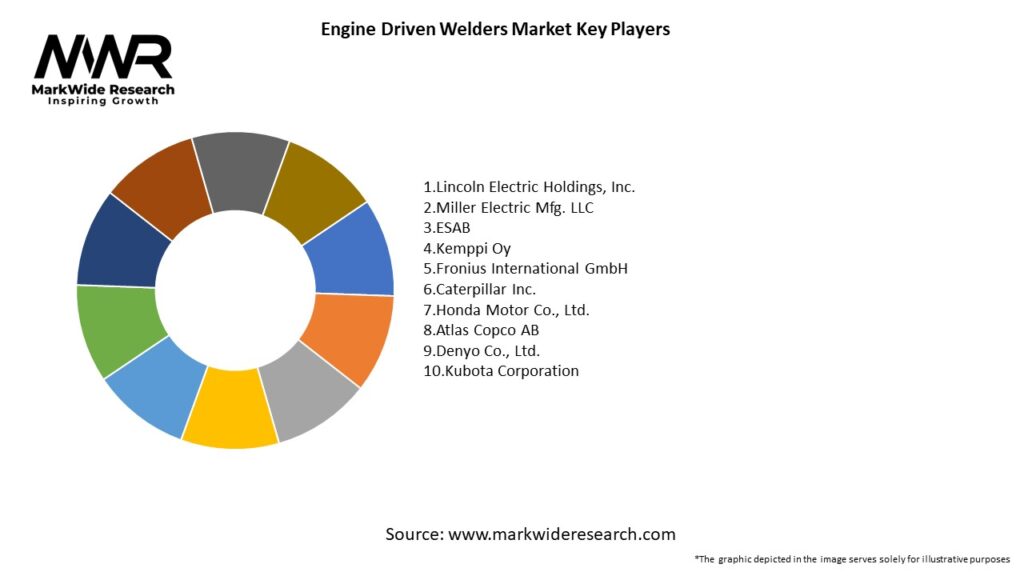

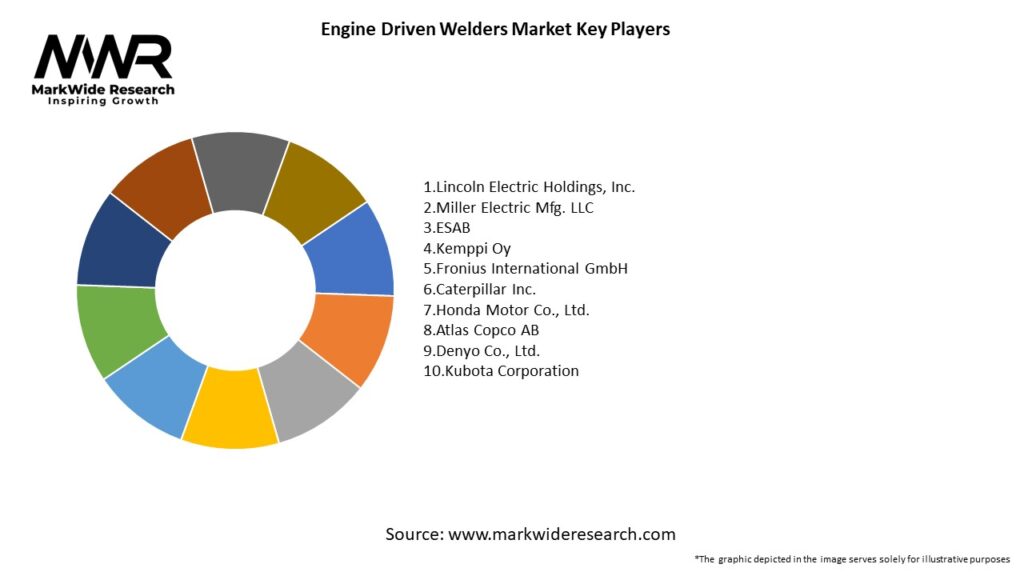

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- The engine driven welders market is projected to grow at a steady pace during the forecast period.

- Portable and compact engine driven welders are in high demand, primarily due to their versatility and convenience.

- Increasing infrastructure development activities worldwide are boosting the demand for engine driven welders.

- The oil and gas industry is a major end-user segment driving the growth of the engine driven welders market.

- Technological advancements in welding processes, such as inverter-based engines and advanced control systems, are positively impacting the market.

Market Drivers

- Growing Infrastructure Development: Rapid urbanization and industrialization have fueled the demand for infrastructure projects, leading to increased adoption of engine driven welders in construction and fabrication activities.

- Rise in Off-Grid Applications: Engine driven welders offer a reliable and self-contained power solution for welding and other operations in remote locations, contributing to their popularity in industries like mining, agriculture, and disaster recovery.

- Portable and Versatile Welding Solutions: The compact size and portability of engine driven welders make them ideal for applications that require mobility, enabling welders to easily transport the equipment to different job sites.

- Efficient Power Generation: Engine driven welders not only provide welding capabilities but also serve as power generators, offering a dual functionality that reduces the need for separate power sources on job sites.

Market Restraints

- High Initial Investment: Engine driven welders are considered a significant investment, which may deter small-scale enterprises or individual welders from adopting these machines, particularly in cost-sensitive regions.

- Environmental Concerns: The emissions produced by engine driven welders are subject to environmental regulations, posing a challenge for manufacturers to develop machines that comply with strict emission standards.

- Technical Complexity: Advanced engine driven welders may require specialized training and knowledge to operate and maintain, limiting their adoption among less-experienced welders.

Market Opportunities

- Integration of Advanced Technologies: The integration of advanced features like digital controls, smart connectivity, and energy-efficient engines presents an opportunity for manufacturers to cater to the evolving needs of end-users and gain a competitive edge.

- Development of Eco-Friendly Engines: As environmental regulations become more stringent, there is a growing need for engine driven welders that minimize emissions and offer sustainable power solutions, creating opportunities for manufacturers to develop eco-friendly models.

- Emerging Markets: The expanding industrial sectors in developing economies present untapped opportunities for engine driven welders, as these regions witness increased construction, infrastructure development, and manufacturing activities.

Market Dynamics

The engine driven welders market is characterized by intense competition and continuous technological advancements. Key market dynamics shaping the industry include:

- Product Innovations: Manufacturers are investing in research and development activities to introduce advanced engine driven welders with improved performance, higher fuel efficiency, and enhanced welding capabilities.

- Strategic Partnerships and Collaborations: Companies are forming strategic alliances with engine and generator manufacturers to leverage their expertise and expand their product portfolios.

- Focus on Environmental Sustainability: With growing environmental concerns, manufacturers are striving to develop engine driven welders that comply with emission regulations and reduce the carbon footprint.

- Customization and Service Offerings: To cater to diverse customer requirements, manufacturers are offering customized engine driven welders and comprehensive after-sales services, including maintenance, training, and technical support.

Regional Analysis

The engine driven welders market exhibits regional variations in terms of demand, market size, and growth opportunities. The key regional segments include:

- North America: The North American market is driven by the presence of well-established industries, such as construction, oil and gas, and manufacturing. The region also experiences a high demand for portable welding solutions in remote areas.

- Europe: Europe showcases a growing demand for engine driven welders due to infrastructure development initiatives, maintenance activities in the manufacturing sector, and the presence of a robust automotive industry.

- Asia Pacific: Rapid urbanization, infrastructure projects, and industrial growth in countries like China, India, and Southeast Asian nations have fueled the demand for engine driven welders in the Asia Pacific region.

- Latin America: Infrastructure development and mining activities in countries like Brazil and Mexico contribute to the demand for engine driven welders in Latin America.

- Middle East and Africa: The Middle East and Africa region exhibit significant potential for engine driven welders, driven by ongoing construction projects, oil and gas operations, and mining activities.

Competitive Landscape

Leading companies in the Engine Driven Welders Market:

- Lincoln Electric Holdings, Inc.

- Miller Electric Mfg. LLC

- ESAB

- Kemppi Oy

- Fronius International GmbH

- Caterpillar Inc.

- Honda Motor Co., Ltd.

- Atlas Copco AB

- Denyo Co., Ltd.

- Kubota Corporation

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

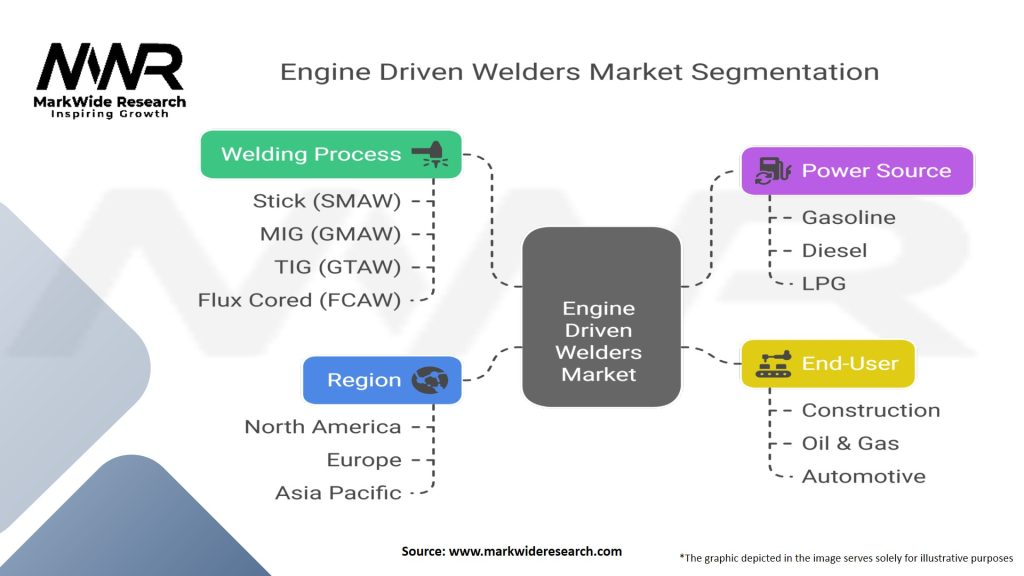

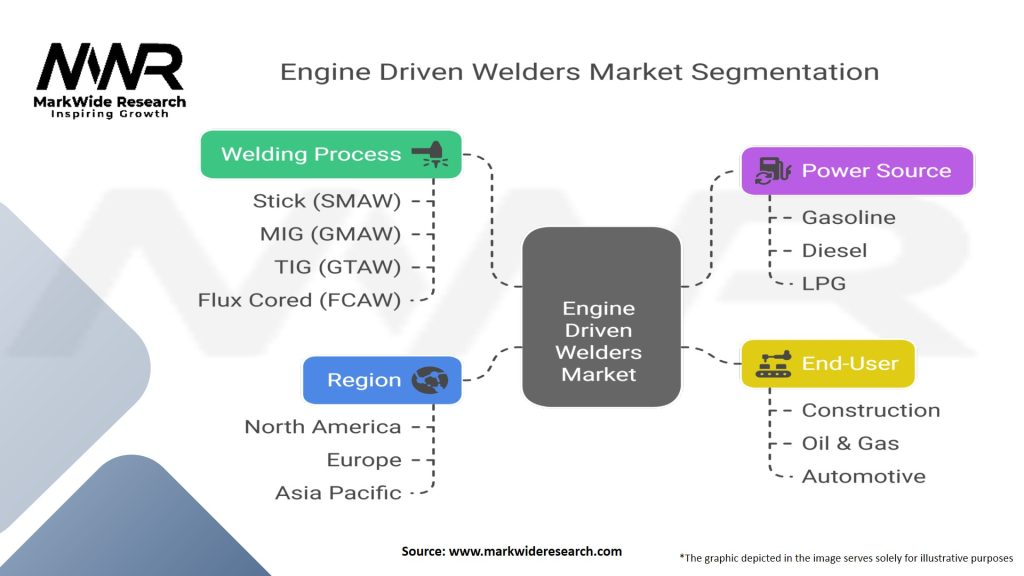

Segmentation

The engine driven welders market can be segmented based on the following criteria:

- By Welding Process:

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW)

- Flux-Cored Arc Welding (FCAW)

- Others (Tungsten Inert Gas, Plasma Arc, etc.)

- By Engine Type:

- By Power Output:

- Below 200 Amps

- 200-400 Amps

- Above 400 Amps

- By End-User Industry:

- Construction

- Oil and Gas

- Manufacturing

- Mining

- Agriculture

- Others (Automotive, Shipbuilding, etc.)

Category-wise Insights

- Construction Sector:

- The construction sector is a significant end-user of engine driven welders, utilizing them for on-site welding and repair activities.

- The demand for engine driven welders in the construction sector is driven by infrastructure development, building construction, and repair and maintenance projects.

- Portable and compact welders are preferred in construction applications, allowing easy movement within construction sites.

- Oil and Gas Industry:

- The oil and gas industry extensively employs engine driven welders for pipeline welding, offshore installations, and repair and maintenance activities.

- The need for welding equipment capable of operating in remote and challenging environments drives the adoption of engine driven welders in the sector.

- Engine driven welders with robust engine performance, high-duty cycles, and advanced safety features are in high demand.

- Manufacturing Sector:

- The manufacturing sector utilizes engine driven welders for fabricating metal structures, equipment repair, and maintenance tasks.

- The versatility and mobility of engine driven welders make them suitable for various welding applications within manufacturing facilities.

- Engine driven welders with advanced control systems and efficient power generation are preferred to improve welding productivity.

- Mining Industry:

- Engine driven welders play a crucial role in the mining industry for repairing and maintaining heavy machinery, equipment, and structures.

- The mining sector often operates in remote and challenging environments, requiring welders that offer reliable power supply and withstand harsh conditions.

- Engine driven welders with rugged designs, high power outputs, and excellent fuel efficiency are in demand in the mining industry.

Key Benefits for Industry Participants and Stakeholders

The engine driven welders market offers several benefits for industry participants and stakeholders, including:

- Welders and Fabricators:

- Portable and compact design enables welders to carry out welding operations in diverse locations, increasing their job opportunities and flexibility.

- Elimination of the need for separate power sources simplifies setup and reduces equipment requirements, enhancing efficiency and productivity.

- Construction Companies:

- Engine driven welders provide on-site power generation and welding capabilities, reducing downtime and increasing operational efficiency.

- The mobility of these welders enables construction companies to work on projects in remote locations without relying on external power sources.

- Oil and Gas Operators:

- Engine driven welders offer a self-contained welding and power generation solution, ensuring uninterrupted operations in offshore and remote oil and gas facilities.

- The versatility and durability of engine driven welders meet the demanding requirements of the oil and gas industry.

- Equipment Rental Companies:

- The high demand for engine driven welders creates lucrative opportunities for equipment rental companies to provide these machines on a short-term or long-term basis.

- Manufacturers:

- Engine driven welders serve as a strategic product offering, allowing manufacturers to diversify their welding equipment portfolio and cater to a wide range of customer needs.

- Advanced technologies integrated into engine driven welders offer a competitive advantage and help manufacturers differentiate their products in the market.

SWOT Analysis

A comprehensive SWOT analysis of the engine driven welders market reveals the following:

- Strengths:

- Versatility and portability of engine driven welders meet the demands of various industries.

- Integration of advanced technologies enhances welding efficiency and power generation capabilities.

- Increasing infrastructure projects worldwide drive the demand for engine driven welders.

- Weaknesses:

- High initial investment required for engine driven welders may limit adoption among small-scale enterprises.

- Environmental concerns regarding emissions pose challenges for manufacturers to comply with stringent regulations.

- Opportunities:

- Integration of advanced features and smart connectivity in engine driven welders provides opportunities for product differentiation.

- Development of eco-friendly engines that reduce emissions aligns with the growing emphasis on environmental sustainability.

- Threats:

- Intense competition in the market from established players and new entrants.

- Economic fluctuations and geopolitical factors impacting infrastructure development projects may affect market growth.

Market Key Trends

The engine driven welders market is influenced by several key trends,including:

- Integration of Advanced Control Systems: Engine driven welders are incorporating advanced control systems, such as digital interfaces and touchscreens, to improve user experience and provide precise control over welding parameters.

- Smart Connectivity and Remote Monitoring: The integration of IoT (Internet of Things) technology enables remote monitoring, diagnostics, and predictive maintenance of engine driven welders, enhancing operational efficiency and minimizing downtime.

- Energy Efficiency and Fuel Optimization: Manufacturers are focusing on developing engines with improved fuel efficiency and optimization algorithms to reduce operating costs and environmental impact.

- Lightweight and Compact Designs: Engine driven welders with lightweight and compact designs are gaining popularity, as they offer ease of transportation and maneuverability, especially in challenging or remote work environments.

- Enhanced Safety Features: Engine driven welders are incorporating advanced safety features, such as thermal overload protection, low oil shutdown, and improved welding safety controls, ensuring operator safety and equipment protection.

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the engine driven welders market.

Positive Impact:

- Demand for Infrastructure Projects: Governments worldwide have initiated infrastructure development projects as part of economic stimulus packages, driving the demand for engine driven welders in construction and related industries.

Negative Impact:

- Supply Chain Disruptions: Disruptions in the global supply chain due to lockdowns and travel restrictions have impacted the production and availability of engine driven welders and their components.

- Delayed Projects: The pandemic has led to project delays and cancellations in various industries, affecting the demand for engine driven welders.

However, as the global economy recovers and construction activities resume, the engine driven welders market is expected to regain its momentum.

Key Industry Developments

- Introduction of Hybrid Engine Driven Welders: Manufacturers are exploring hybrid engine driven welders that combine traditional engine technologies with battery-powered systems, providing more versatility and energy-efficient options.

- Focus on Emission Reduction: Engine driven welder manufacturers are investing in research and development to develop engines that comply with stringent emission standards, reducing environmental impact and meeting regulatory requirements.

- Integration of Artificial Intelligence: Some engine driven welders are incorporating artificial intelligence algorithms for improved welding performance, automatic parameter adjustment, and predictive maintenance.

- Expansion of Distribution Networks: Manufacturers are expanding their distribution networks to reach untapped markets and strengthen their presence globally, ensuring wider availability of engine driven welders.

Analyst Suggestions

- Continuous Technological Advancements: Manufacturers should focus on research and development to introduce innovative features, enhance welding efficiency, and improve fuel optimization in engine driven welders.

- Customization and Value-added Services: Offering customized engine driven welders and comprehensive after-sales services, including training, technical support, and maintenance, can provide a competitive edge and enhance customer satisfaction.

- Strategic Partnerships and Collaborations: Collaborating with engine and generator manufacturers can provide access to advanced technologies and expertise, enabling manufacturers to develop superior engine driven welders.

- Environmental Sustainability: Manufacturers should prioritize the development of eco-friendly engines with reduced emissions to align with environmental regulations and address the increasing demand for sustainable welding solutions.

Future Outlook

The engine driven welders market is expected to witness steady growth in the coming years, driven by ongoing infrastructure development projects, industrialization, and the need for portable and efficient welding solutions. Technological advancements, such as smart connectivity, energy efficiency, and improved engine performance, will continue to shape the market. Manufacturers will focus on customization, value-added services, and partnerships to meet the evolving demands of end-users and gain a competitive advantage.

Conclusion

The engine driven welders market is experiencing significant growth, driven by the demand for portable, efficient, and versatile welding solutions across various industries. Engine driven welders offer the convenience of on-site power generation and welding capabilities in a single unit, making them indispensable for remote locations and areas without access to electricity. Despite challenges related to initial investment and emissions, the market presents opportunities for product innovation, eco-friendly solutions, and expansion into emerging markets. Continuous technological advancements, strategic partnerships, and a focus on environmental sustainability will shape the future of the engine driven welders market, providing industry participants and stakeholders with a range of benefits and opportunities for growth.