444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The marine industry plays a significant role in global trade and transportation, and the emission control catalyst for the marine market is gaining prominence due to environmental regulations and sustainability concerns. Emission control catalysts are crucial components used in marine engines to reduce harmful emissions, such as nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM). These catalysts assist in the conversion of pollutants into less harmful substances before they are released into the atmosphere. The demand for emission control catalysts in the marine sector is expected to grow steadily in the coming years as stricter emission regulations are implemented worldwide.

Meaning

Emission control catalysts for the marine market are advanced technological solutions designed to address the environmental challenges associated with marine engine emissions. These catalysts are typically composed of precious metals, such as platinum, palladium, and rhodium, which act as catalysts in the chemical reactions that convert harmful pollutants into less toxic substances. By facilitating these reactions, emission control catalysts help reduce the environmental impact of marine vessels and promote cleaner air quality. These catalysts are installed in the exhaust systems of marine engines, where they effectively control emissions and enable compliance with stringent regulatory standards.

Executive Summary

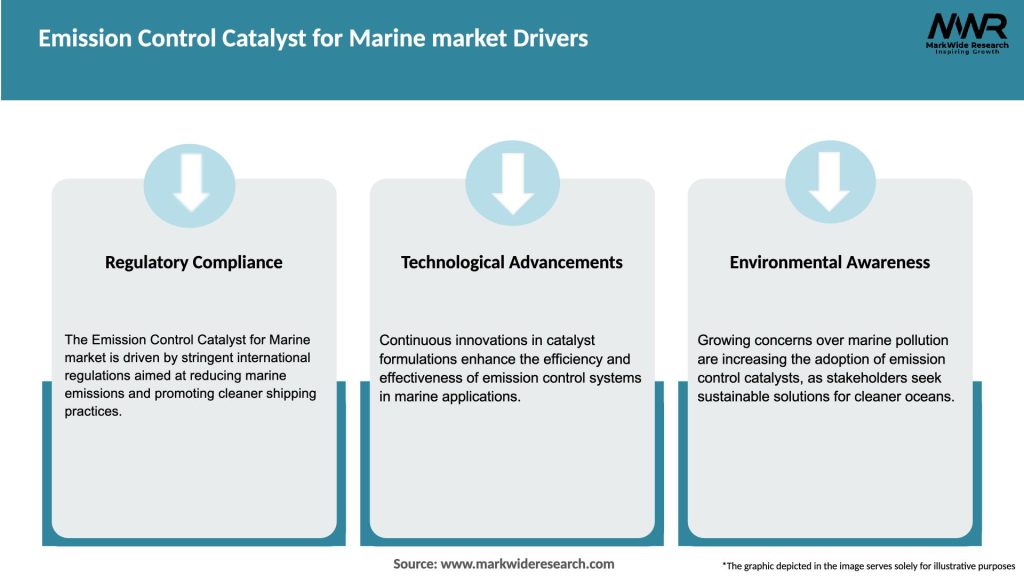

The emission control catalyst for the marine market is witnessing significant growth due to increasing environmental concerns and the implementation of strict emission control regulations by governing bodies across the globe. The demand for emission control catalysts is primarily driven by the need to reduce harmful emissions from marine engines, such as NOx, SOx, and PM. Stringent regulations, such as the International Maritime Organization’s (IMO) MARPOL Annex VI, have mandated the use of emission control catalysts to ensure compliance with emission limits. The market is characterized by the presence of established manufacturers offering technologically advanced catalyst solutions that meet regulatory requirements while delivering optimum performance. The market is expected to witness substantial growth in the coming years, driven by increasing awareness of environmental sustainability and the growing focus on reducing marine pollution.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The emission control catalyst market for the marine sector is influenced by various dynamics, including regulatory developments, technological advancements, and market competition. The following factors shape the market landscape:

Regional Analysis

The emission control catalyst market for the marine sector exhibits regional variations due to differences in emission regulations, vessel types, and environmental priorities. The market can be divided intoseveral key regions:

Each region presents unique market dynamics, including regulatory frameworks, industry size, environmental priorities, and technological advancements. Manufacturers operating in these regions need to consider these factors to tailor their catalyst solutions and effectively penetrate the respective markets.

Competitive Landscape

Leading Companies in the Emission Control Catalyst for Marine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

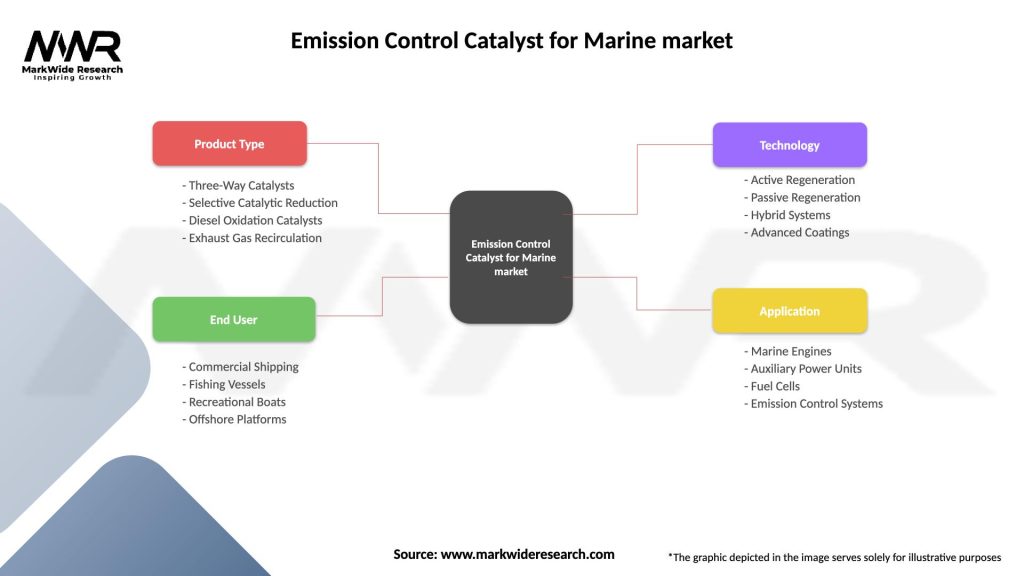

The emission control catalyst market for the marine sector can be segmented based on various factors, including catalyst type, vessel type, and geography.

Segmenting the market allows for a better understanding of specific market segments and enables manufacturers to target their products and services accordingly.

Category-wise Insights

Understanding the specific characteristics and applications of different catalyst types helps stakeholders make informed decisions and select the most suitable catalyst solutions for their marine operations.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides an overview of the emission control catalyst market for the marine sector:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the marine industry, including the emission control catalyst market. The pandemic disrupted global trade, leading to reduced shipping activity and vessel utilization. This slowdown in the maritime sector affected the demand for emission control catalysts, as vessel owners prioritized cost-saving measures over environmental compliance investments.

However, the pandemic also highlighted the importance of sustainable practices and environmental responsibility. As the industry recovers from the pandemic’s impact, there is a renewed focus on emissions reduction and compliance with environmental regulations. This presents an opportunity for the emission control catalyst market to regain momentum as the maritime industry strives for greener and cleaner operations.

Key Industry Developments

Analyst Suggestions

Future Outlook

The emission control catalyst market for the marine sector is expected to witness steady growth in the coming years. Stricter emission regulations, growing environmental awareness, and the need for sustainable shipping practices will drive the demand for emission control catalysts. Technological advancements, including the integration of digital technologies and the development of multi-pollutant catalysts, will further enhance catalyst efficiency and performance. Collaboration among stakeholders and increased focus on retrofit opportunities will also contribute to market expansion. Despite challenges such as high initial costs and regional variations in regulations, the emission control catalyst market holds significant potential for manufacturers, service providers, and vessel owners looking to achieve compliance and promote sustainable marine operations.

Conclusion

The emission control catalyst market for the marine sector is witnessing significant growth driven by increasing environmental concerns, stricter emission regulations, and the need for sustainable shipping practices. Emission control catalysts play a crucial role in reducing harmful emissions from marine engines, ensuring compliance with regulatory standards and promoting cleaner air quality. The market offers opportunities for manufacturers and service providers to develop advanced catalyst solutions that improve efficiency, durability, and adaptability. Collaboration among stakeholders, education and awareness programs, and government incentives can further drive the adoption of emission control catalysts. As the industry recovers from the Covid-19 pandemic, the focus on emissions reduction and environmental responsibility will lead to a renewed emphasis on emission control catalysts, paving the way for a greener and cleaner future in the marine sector.

What is Emission Control Catalyst for Marine?

Emission Control Catalyst for Marine refers to specialized catalytic converters designed to reduce harmful emissions from marine engines. These catalysts help in converting toxic gases into less harmful substances, thereby improving air quality and complying with environmental regulations.

What are the key players in the Emission Control Catalyst for Marine market?

Key players in the Emission Control Catalyst for Marine market include companies like Johnson Matthey, BASF, and Haldor Topsoe, which are known for their innovative catalytic solutions. These companies focus on developing advanced technologies to enhance emission control in marine applications, among others.

What are the growth factors driving the Emission Control Catalyst for Marine market?

The growth of the Emission Control Catalyst for Marine market is driven by increasing regulatory pressure to reduce emissions from ships and the rising demand for cleaner marine fuels. Additionally, advancements in catalyst technology and growing awareness of environmental sustainability are contributing to market expansion.

What challenges does the Emission Control Catalyst for Marine market face?

The Emission Control Catalyst for Marine market faces challenges such as high costs associated with catalyst materials and the need for regular maintenance. Furthermore, the variability in fuel quality and the complexity of retrofitting existing vessels with new technologies can hinder market growth.

What opportunities exist in the Emission Control Catalyst for Marine market?

Opportunities in the Emission Control Catalyst for Marine market include the development of next-generation catalysts that offer higher efficiency and lower costs. Additionally, the increasing adoption of alternative fuels and the expansion of international regulations present significant growth potential for innovative solutions.

What trends are shaping the Emission Control Catalyst for Marine market?

Trends in the Emission Control Catalyst for Marine market include the shift towards hybrid and electric marine vessels, which require advanced emission control technologies. Moreover, the integration of digital monitoring systems for real-time emissions tracking is becoming increasingly popular among marine operators.

Emission Control Catalyst for Marine market

| Segmentation Details | Description |

|---|---|

| Product Type | Three-Way Catalysts, Selective Catalytic Reduction, Diesel Oxidation Catalysts, Exhaust Gas Recirculation |

| End User | Commercial Shipping, Fishing Vessels, Recreational Boats, Offshore Platforms |

| Technology | Active Regeneration, Passive Regeneration, Hybrid Systems, Advanced Coatings |

| Application | Marine Engines, Auxiliary Power Units, Fuel Cells, Emission Control Systems |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Emission Control Catalyst for Marine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at