444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Electronic prototyping refers to the process of developing and testing electronic circuits and systems before they are mass-produced. It involves creating a physical prototype of a design concept to evaluate its functionality, performance, and feasibility. This process plays a crucial role in the development of new electronic products and technologies.

Meaning

Electronic prototyping is the initial stage in the product development lifecycle where engineers and designers bring their ideas to life by building and testing working prototypes. It involves the use of various tools, components, and software to design, assemble, and validate electronic systems.

Executive Summary

The electronic prototyping market has witnessed significant growth in recent years. The increasing demand for innovative electronic products, advancements in technology, and the need for faster time-to-market have been the key drivers for market expansion. This market offers a wide range of prototyping tools, such as software simulation, breadboards, development boards, and 3D printing, which enable engineers to build and test their designs efficiently.

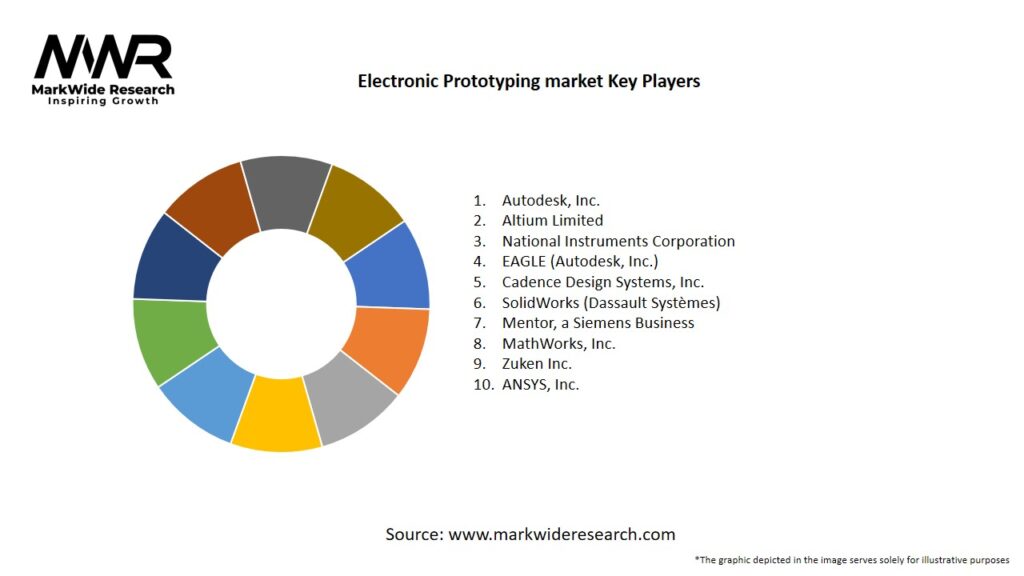

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The electronic prototyping market is driven by a combination of factors, including technological advancements, changing consumer demands, and industry collaborations. The market is highly dynamic, with continuous innovations and the introduction of new tools and techniques. Collaboration between manufacturers, designers, and engineers is becoming more prevalent, leading to the development of comprehensive prototyping solutions.

Regional Analysis

The electronic prototyping market exhibits a global presence, with key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. North America has traditionally been at the forefront of technological advancements and innovation, driving the growth of the electronic prototyping market. However, Asia Pacific is experiencing rapid growth due to the presence of major electronics manufacturers and the increasing adoption of IoT devices in countries like China, India, and Japan.

Competitive Landscape

Leading Companies in the Electronic Prototyping Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The electronic prototyping market can be segmented based on the type of prototyping tools, applications, end-users, and regions. By type, the market can be categorized into software simulation tools, breadboards and development boards, 3D printing, and others. Applications of electronic prototyping include consumer electronics, automotive, healthcare, aerospace, industrial automation, and others. The market serves various end-users, including large enterprises, SMEs, and individual inventors.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had both positive and negative impacts on the electronic prototyping market. On one hand, the increased adoption of remote work and online collaboration tools has fueled the demand for virtual prototyping and simulation software. Engineers and designers have leveraged these tools to continue their prototyping activities despite physical limitations.

However, the pandemic has also disrupted global supply chains, leading to component shortages and delays in prototyping projects. Travel restrictions and social distancing measures have impacted the ability to conduct physical testing and validation, causing setbacks in product development timelines.

Key Industry Developments

Analyst Suggestions

Future Outlook

The electronic prototyping market is poised for significant growth in the coming years. The demand for innovative electronic products, coupled with advancements in technology and the need for faster time-to-market, will continue to drive market expansion. The integration of AI, machine learning, and IoT capabilities in prototyping tools will further enhance the efficiency and accuracy of the prototyping process. The market will also witness increased collaboration and knowledge sharing among industry players, leading to the development of comprehensive and cost-effective prototyping solutions.

Conclusion

The electronic prototyping market is a vital component of the product development lifecycle, enabling engineers and designers to bring their ideas to life. With the growing demand for innovative electronic products, advancements in technology, and the need for faster time-to-market, the market is experiencing significant growth. While facing challenges such as high initial setup costs and skill gaps, the market offers substantial opportunities driven by the rise of IoT devices, additive manufacturing, and collaborative prototyping platforms. By embracing these trends, fostering collaboration, and investing in talent development, industry participants can leverage the benefits of electronic prototyping and drive future innovation in the electronic industry.

What is Electronic Prototyping?

Electronic prototyping refers to the process of creating a preliminary model of an electronic device or system. This involves designing and testing circuits, components, and software to validate concepts before full-scale production.

What are the key players in the Electronic Prototyping market?

Key players in the Electronic Prototyping market include companies like Arduino, Raspberry Pi, and Texas Instruments, which provide essential tools and platforms for prototyping electronic devices, among others.

What are the main drivers of growth in the Electronic Prototyping market?

The growth of the Electronic Prototyping market is driven by the increasing demand for rapid prototyping in product development, the rise of IoT applications, and the need for cost-effective solutions in electronics design.

What challenges does the Electronic Prototyping market face?

Challenges in the Electronic Prototyping market include the complexity of integrating various technologies, the rapid pace of innovation requiring constant updates, and the need for skilled personnel to manage prototyping processes.

What opportunities exist in the Electronic Prototyping market?

Opportunities in the Electronic Prototyping market include the expansion of smart devices, advancements in 3D printing technologies for electronic components, and the growing trend of DIY electronics among hobbyists and startups.

What trends are shaping the Electronic Prototyping market?

Trends in the Electronic Prototyping market include the increasing use of open-source hardware, the integration of artificial intelligence in design processes, and the growing popularity of cloud-based prototyping tools.

Electronic Prototyping market

| Segmentation Details | Description |

|---|---|

| Product Type | Development Boards, Prototyping Tools, Simulation Software, Test Equipment |

| Technology | 3D Printing, PCB Design, Embedded Systems, IoT Solutions |

| End User | Startups, Educational Institutions, R&D Departments, Manufacturing Firms |

| Application | Consumer Electronics, Automotive Prototyping, Industrial Automation, Medical Devices |

Leading Companies in the Electronic Prototyping Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at