444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview The electron beam welding systems market represents a critical segment within the welding and joining technologies industry, offering precision, efficiency, and versatility in high-performance welding applications. These systems harness electron beams to produce high-quality welds with minimal heat input, making them indispensable in aerospace, automotive, medical, and semiconductor manufacturing sectors.

Meaning Electron beam welding systems employ focused electron beams to generate localized heat and join metallic components with precision and efficiency. These systems facilitate high-quality welds with minimal distortion, enabling manufacturers to achieve superior weld integrity and mechanical properties in critical applications.

Executive Summary The electron beam welding systems market stands at the forefront of welding technology innovation, driven by the demand for high-performance welding solutions in aerospace, automotive, and electronics manufacturing industries. With their ability to deliver precise, distortion-free welds, electron beam welding systems offer unparalleled advantages in critical applications requiring superior weld quality and mechanical performance.

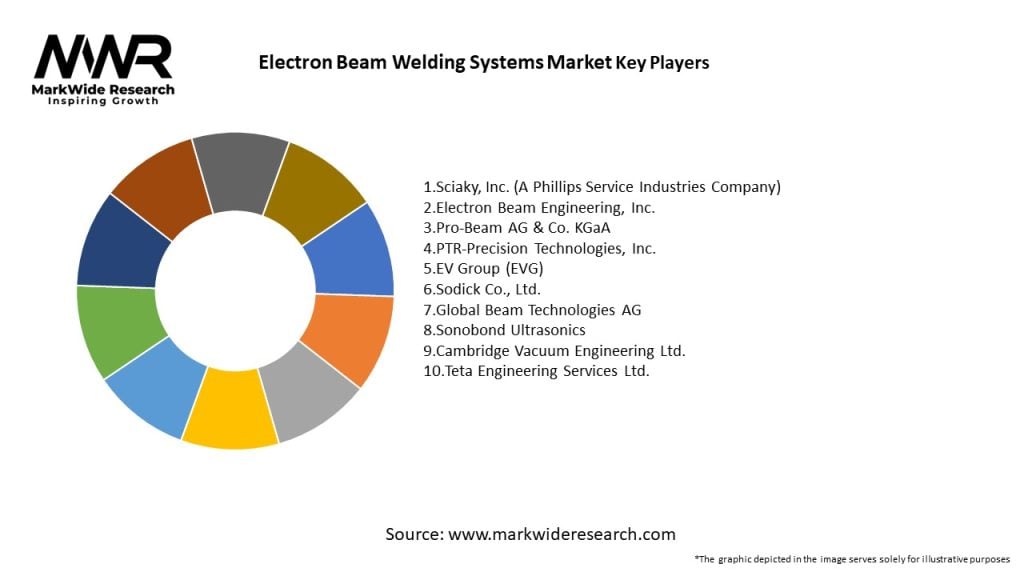

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics The electron beam welding systems market operates within a dynamic landscape shaped by technological advancements, industry trends, regulatory requirements, and competitive dynamics. Navigating these dynamics requires manufacturers to demonstrate agility, innovation, and customer-centricity to maintain competitive advantage and market leadership.

Regional Analysis The regional dynamics of the electron beam welding systems market vary based on factors such as manufacturing capabilities, industry verticals, technological advancements, and regulatory environments. From the aerospace hubs in North America to the automotive manufacturing centers in Europe and Asia-Pacific, each region presents unique opportunities and challenges for market players.

Competitive Landscape

Leading Companies in the Electron Beam Welding Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

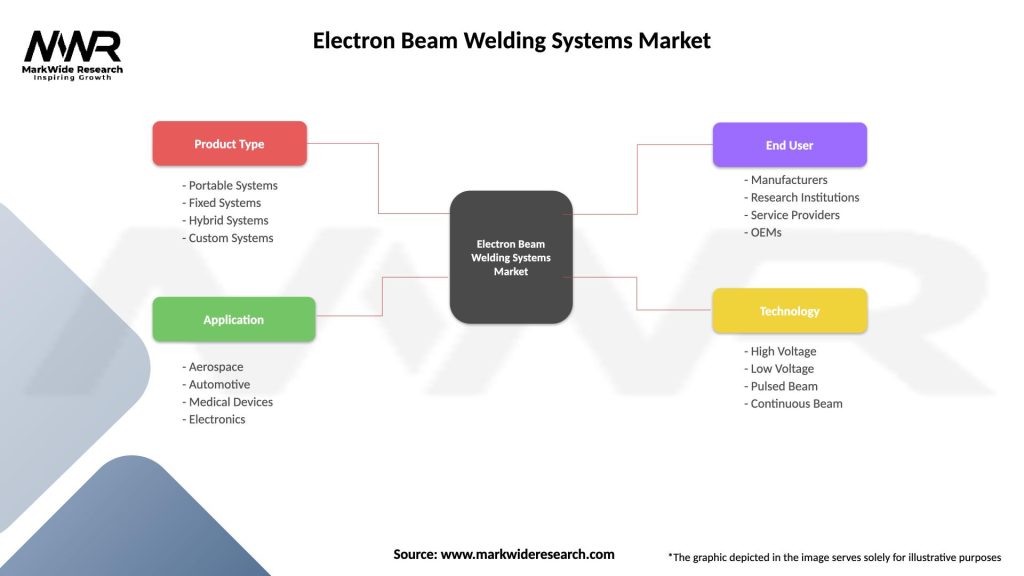

Segmentation The electron beam welding systems market can be segmented based on various parameters, including system type, application, end-user industry, and geographical region. Segmentation enables market players to target specific customer segments, tailor their offerings, and optimize resource allocation for maximum impact.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact The Covid-19 pandemic exerted multifaceted impacts on the electron beam welding systems market, disrupting supply chains, delaying projects, and reshaping market dynamics. From fluctuating demand to workforce challenges and project cancellations, Covid-19 introduced unprecedented uncertainties and disruptions for industry players.

Key Industry Developments

Analyst Suggestions

Future Outlook The future of the electron beam welding systems market holds promise and potential, driven by technological advancements, industry trends, and market dynamics. From additive manufacturing innovations to industry 4.0 integration and sustainability initiatives, the market charts a course towards innovation, resilience, and sustainable growth in the years ahead.

Conclusion:

In conclusion, the electron beam welding systems market is poised for significant growth, driven by advancements in precision manufacturing and the increasing demand for high-quality welds in industries such as aerospace, automotive, and electronics. The ability of electron beam welding to deliver superior results in terms of joint strength and minimal thermal distortion positions it as a preferred choice for complex applications. Emerging opportunities are notably present in the integration of automation and robotics, which enhance operational efficiency and reduce production costs. Furthermore, the ongoing trend toward lightweight materials and the need for sustainable manufacturing processes are likely to accelerate the adoption of these systems. However, challenges such as high initial investment costs and the need for skilled operators must be addressed to fully capitalize on market potential. Stakeholders, including manufacturers and end-users, must stay attuned to technological innovations and evolving regulatory standards to navigate the competitive landscape effectively. As the market continues to evolve, strategic collaborations and investments in research and development will be crucial in unlocking new applications and expanding market reach. Overall, the electron beam welding systems market presents a promising outlook, with the potential for significant advancements that will redefine manufacturing capabilities and drive future growth.

What is Electron Beam Welding Systems?

Electron Beam Welding Systems are advanced welding technologies that utilize a focused beam of electrons to join materials, typically metals. This process is known for its precision and ability to weld complex geometries with minimal thermal distortion.

What are the key players in the Electron Beam Welding Systems Market?

Key players in the Electron Beam Welding Systems Market include companies like General Electric, Mitsubishi Electric, and IHI Corporation, which are known for their innovative welding solutions and technologies, among others.

What are the main drivers of growth in the Electron Beam Welding Systems Market?

The growth of the Electron Beam Welding Systems Market is driven by the increasing demand for high-precision welding in industries such as aerospace, automotive, and electronics. Additionally, the need for efficient and cost-effective manufacturing processes contributes to market expansion.

What challenges does the Electron Beam Welding Systems Market face?

Challenges in the Electron Beam Welding Systems Market include the high initial investment costs and the need for skilled operators to manage the technology effectively. Furthermore, competition from alternative welding methods can also pose a challenge.

What opportunities exist in the Electron Beam Welding Systems Market?

The Electron Beam Welding Systems Market presents opportunities for growth through advancements in automation and integration with Industry Four Point Zero technologies. Additionally, expanding applications in medical device manufacturing and renewable energy sectors are promising.

What trends are shaping the Electron Beam Welding Systems Market?

Trends in the Electron Beam Welding Systems Market include the increasing adoption of hybrid welding techniques and the development of portable electron beam welding systems. These innovations are enhancing flexibility and efficiency in various industrial applications.

Electron Beam Welding Systems Market

| Segmentation Details | Description |

|---|---|

| Product Type | Portable Systems, Fixed Systems, Hybrid Systems, Custom Systems |

| Application | Aerospace, Automotive, Medical Devices, Electronics |

| End User | Manufacturers, Research Institutions, Service Providers, OEMs |

| Technology | High Voltage, Low Voltage, Pulsed Beam, Continuous Beam |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Electron Beam Welding Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at