444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The electrical appliance coatings market refers to the industry that focuses on the production and application of specialized coatings for electrical appliances. These coatings serve various purposes, such as providing insulation, protection against corrosion, and enhancing the aesthetic appeal of electrical devices. This comprehensive market analysis will delve into the key aspects of the electrical appliance coatings industry, including market drivers, restraints, opportunities, regional analysis, competitive landscape, segmentation, key trends, the impact of Covid-19, industry developments, analyst suggestions, future outlook, and a conclusive summary.

Electrical appliance coatings are specially formulated coatings that are designed to meet the unique requirements of electrical devices. These coatings are applied to the surfaces of appliances, such as refrigerators, washing machines, air conditioners, and televisions, to enhance their performance and longevity. The coatings act as a protective layer, safeguarding the appliances from external factors such as moisture, heat, and mechanical stress.

Executive Summary

The electrical appliance coatings market has witnessed significant growth in recent years, driven by the increasing demand for durable and visually appealing electrical devices across residential, commercial, and industrial sectors. The market is characterized by the presence of several key players offering a wide range of coating solutions. This executive summary provides a concise overview of the key findings and insights presented in this market analysis.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The growth of the Electrical Appliance Coatings Market is driven by several factors:

Expansion of the Electrical Appliance Industry: The growing demand for household appliances, including refrigerators, washing machines, air conditioners, and kitchen appliances, is driving the need for coatings that enhance their durability and performance.

Consumer Preference for Durability and Aesthetics: Consumers are increasingly demanding appliances that are not only functional but also visually appealing. This trend is pushing manufacturers to use coatings that provide a polished appearance while ensuring long-lasting protection.

Technological Advancements in Coating Materials: The development of high-performance coatings with better corrosion resistance, electrical insulation, and heat resistance is a key factor driving the market’s growth. Coatings that improve appliance efficiency and reduce energy consumption are particularly in demand.

Environmental and Sustainability Concerns: The push for eco-friendly products and coatings that have a minimal environmental impact is accelerating market growth. Manufacturers are opting for non-toxic, biodegradable coatings that meet sustainability standards.

Energy Efficiency and Regulatory Compliance: With increasing regulations around energy efficiency and environmental impact, manufacturers are focusing on creating coatings that enhance the overall energy performance of electrical appliances.

Market Restraints

Despite its growth prospects, the Electrical Appliance Coatings Market faces several challenges:

High Cost of Advanced Coatings: The cost of advanced, high-performance coatings, such as those providing superior heat resistance and electrical insulation, can be high. This may limit the adoption of these coatings, particularly in cost-sensitive markets.

Complex Manufacturing Processes: The application of coatings to electrical appliance components requires precise manufacturing techniques and can increase production time and costs. This complexity may hinder the widespread adoption of certain coatings.

Environmental Concerns with Traditional Coatings: Traditional coatings, particularly those containing volatile organic compounds (VOCs), can pose environmental and health risks. The shift toward eco-friendly alternatives requires significant investment in research and development.

Market Competition and Price Sensitivity: The electrical appliance coatings market is highly competitive, with several players offering a wide range of products. Price sensitivity among manufacturers may limit the adoption of premium coatings.

Market Opportunities

The Electrical Appliance Coatings Market presents several opportunities for growth:

Eco-Friendly and Sustainable Coatings: With growing consumer awareness of environmental issues, there is a rising demand for eco-friendly and sustainable coatings that offer high performance with minimal environmental impact. This presents opportunities for companies that specialize in green coatings.

Growth of Smart Homes: The rapid growth of smart homes and the increasing adoption of IoT-enabled appliances present significant opportunities for the development of coatings tailored to the needs of these advanced devices, including enhanced protection, durability, and aesthetics.

Regional Expansion in Emerging Markets: The rise of middle-class populations and increasing disposable incomes in emerging markets such as Asia-Pacific and Latin America present growth opportunities for the electrical appliance coatings market.

Customization and Innovation: Manufacturers that focus on developing customized coatings that meet specific needs, such as anti-microbial coatings or coatings that improve energy efficiency, are likely to gain a competitive edge in the market.

Market Dynamics

The Electrical Appliance Coatings Market is influenced by several dynamic factors:

Technological Advancements: New developments in coating materials, such as thermally stable coatings, corrosion-resistant coatings, and low-emission coatings, are improving the overall performance and durability of electrical appliances, driving the market forward.

Consumer Demand for Multi-Functional Products: Consumers increasingly demand appliances that offer more functionality with enhanced aesthetics, creating the need for coatings that serve both protective and decorative purposes.

Sustainability Initiatives: With increasing environmental regulations and pressure from consumers for sustainable products, manufacturers are adopting eco-friendly coatings made from non-toxic and biodegradable materials.

Industry 4.0 and Automation: Automation in manufacturing processes is improving the efficiency and consistency of coating applications, contributing to the overall growth of the market.

Regional Analysis

The Electrical Appliance Coatings Market is segmented by key regions:

North America: The North American market is one of the largest for electrical appliance coatings, driven by the high demand for household appliances and strict environmental regulations. The U.S. and Canada are key contributors to market growth, with a focus on energy-efficient products.

Europe: Europe is a significant market for electrical appliance coatings, especially in countries like Germany, France, and the UK, which have a strong manufacturing base and a high demand for eco-friendly and energy-efficient appliances.

Asia-Pacific: Asia-Pacific is expected to be the fastest-growing region in the electrical appliance coatings market, driven by rapid industrialization, growing disposable income, and an increasing demand for consumer electronics and household appliances in countries like China, India, and Japan.

Latin America and Middle East & Africa: The market in these regions is growing due to rising urbanization, increased purchasing power, and expanding middle-class populations, which are driving the demand for household appliances and durable coatings.

Competitive Landscape

Leading Companies in the Electrical Appliance Coatings Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

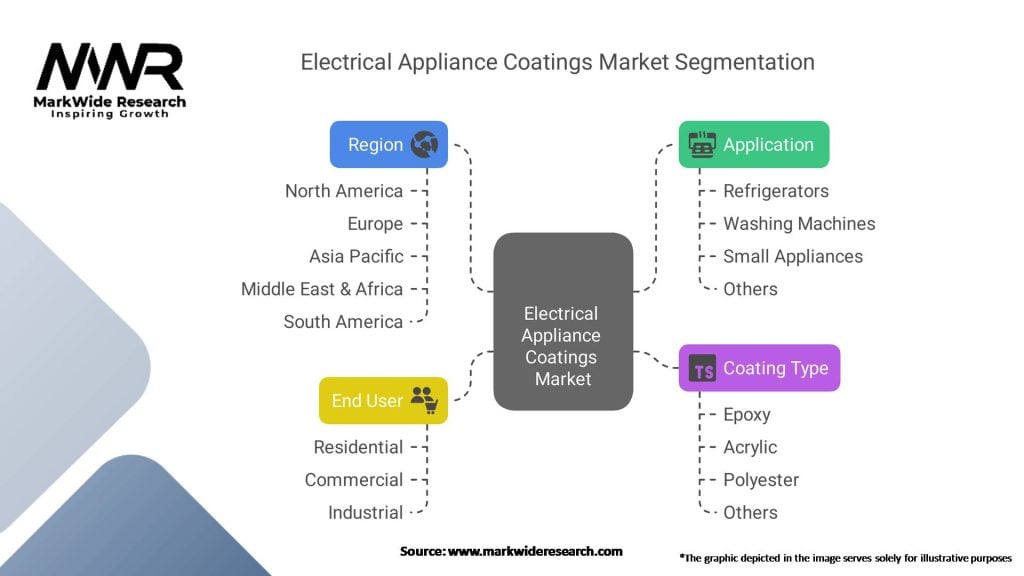

Segmentation

The Electrical Appliance Coatings Market can be segmented based on the following factors:

Type: Powder Coatings, Liquid Coatings, Thermal Barrier Coatings.

End-Use Industry: Household Appliances, Kitchen Appliances, HVAC Systems, Consumer Electronics.

Application: Protective Coatings, Aesthetic Coatings, Insulating Coatings, Corrosion-Resistant Coatings.

Category-wise Insights

Powder Coatings: Powder coatings are gaining popularity in the electrical appliance market due to their durability, environmental benefits, and ability to create high-quality finishes.

Liquid Coatings: Liquid coatings offer versatility and are commonly used in electrical appliances requiring fine finishes and coatings for smaller components.

Thermal Barrier Coatings: These coatings are essential for appliances that experience high temperatures, such as ovens and HVAC systems, providing protection against heat and improving energy efficiency.

Key Benefits for Industry Participants and Stakeholders

Cost-Effective Production: Electrical appliance manufacturers benefit from coatings that provide both aesthetic and functional benefits, improving product quality and longevity while reducing production costs.

Enhanced Durability: Coatings that improve resistance to heat, moisture, and corrosion increase the lifespan of electrical appliances, reducing maintenance costs and improving customer satisfaction.

Sustainability: Eco-friendly coatings help manufacturers meet sustainability goals and comply with environmental regulations, making them more attractive to environmentally conscious consumers.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Key trends shaping the Electrical Appliance Coatings Market include:

Sustainability: Growing demand for eco-friendly, non-toxic coatings is pushing manufacturers to innovate and reduce environmental impact.

Customization: Increased demand for customized coatings that improve functionality and design appeal is driving innovation in the market.

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on various industries, including the electrical appliance coatings market. This section analyzes the effects of the pandemic on the market, including supply chain disruptions, demand fluctuations, and changing consumer behavior. It provides insights into the short-term and long-term implications of the pandemic and suggests strategies to navigate the challenges.

Key Industry Developments

This section highlights the key developments and innovations within the electrical appliance coatings industry. It includes product launches, mergers and acquisitions, collaborations, and partnerships among market players. These developments shape the industry landscape and influence market growth and competitiveness.

Analyst Suggestions

Based on the analysis and insights presented in this report, our analysts provide suggestions and recommendations for industry participants to capitalize on market opportunities, mitigate risks, and drive business growth. These suggestions are aimed at assisting companies in making informed decisions and staying competitive in the dynamic market environment.

Future Outlook

This section offers a forward-looking perspective on the electrical appliance coatings market, taking into account various factors such as market trends, technological advancements, and regulatory landscape. It provides insights into the expected market size, growth rate, and emerging opportunities over the forecast period. Industry participants can use this outlook to strategize their long-term plans and investments.

Conclusion

In conclusion, the electrical appliance coatings market is witnessing steady growth due to increasing consumer demand for durable and visually appealing electrical devices. The market offers lucrative opportunities for industry participants to develop innovative coating solutions and cater to the evolving needs of the industry. By understanding the market dynamics, regional trends, competitive landscape, and emerging opportunities, stakeholders can position themselves for success in this thriving market.

What are electrical appliance coatings?

Electrical appliance coatings are specialized materials applied to the surfaces of electrical appliances to enhance their durability, aesthetic appeal, and resistance to environmental factors. These coatings can include paints, varnishes, and other protective layers that improve performance and longevity.

What are the key companies in the electrical appliance coatings market?

Key companies in the electrical appliance coatings market include PPG Industries, AkzoNobel, Sherwin-Williams, and BASF, among others.

What are the growth factors driving the electrical appliance coatings market?

The growth of the electrical appliance coatings market is driven by increasing consumer demand for durable and aesthetically pleasing appliances, advancements in coating technologies, and the rising trend of energy-efficient appliances that require specialized coatings.

What challenges does the electrical appliance coatings market face?

The electrical appliance coatings market faces challenges such as stringent environmental regulations regarding volatile organic compounds (VOCs) in coatings, competition from alternative materials, and fluctuations in raw material prices that can impact production costs.

What opportunities exist in the electrical appliance coatings market?

Opportunities in the electrical appliance coatings market include the development of eco-friendly coatings, innovations in nanotechnology for improved performance, and the expansion of the market in emerging economies where appliance demand is growing.

What trends are shaping the electrical appliance coatings market?

Trends in the electrical appliance coatings market include the increasing use of smart coatings that provide additional functionalities, the shift towards sustainable and low-emission coatings, and the growing popularity of customized finishes that cater to consumer preferences.

Electrical Appliance Coatings Market

| Segmentation | Details |

|---|---|

| Application | Refrigerators, Washing Machines, Small Appliances, Others |

| Coating Type | Epoxy, Acrylic, Polyester, Others |

| End User | Residential, Commercial, Industrial |

| Region | North America, Europe, Asia Pacific, Middle East & Africa, South America |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Electrical Appliance Coatings Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at