444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Electric Flow Control Ball Valves market is experiencing significant growth, driven by the increasing demand for advanced flow control solutions in various industries such as oil and gas, water treatment, HVAC, and process automation. Electric flow control ball valves are precision-engineered devices designed to regulate fluid flow in pipelines, HVAC systems, and industrial processes using electric actuators for precise control and automation. With the growing emphasis on energy efficiency, environmental sustainability, and operational optimization, the adoption of electric flow control ball valves is on the rise, driving market expansion across different applications and end-user sectors.

Meaning

Electric flow control ball valves are specialized valves equipped with electric actuators for remote control, automation, and regulation of fluid flow in pipelines, HVAC systems, and industrial processes. These valves feature a spherical closure element (ball) with a through hole, which rotates to regulate the flow of liquids or gases through the valve body. Electric actuators provide the necessary torque to open, close, or modulate the valve, enabling precise control over flow rates, pressure levels, and fluid handling operations. Electric flow control ball valves offer advantages such as rapid response times, accurate positioning, and compatibility with digital control systems, making them ideal for applications requiring reliable flow control and automation.

Executive Summary

The Electric Flow Control Ball Valves market is witnessing rapid growth, fueled by the increasing demand for energy-efficient, environmentally friendly, and digitally integrated flow control solutions across industrial and commercial sectors. Key factors driving market expansion include advancements in valve technology, the transition towards smart and connected systems, and the growing adoption of automation and process optimization solutions. Despite challenges such as price competition and technical complexities, the market is poised for sustained growth, driven by emerging opportunities in renewable energy, smart infrastructure, and digital manufacturing.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Electric Flow Control Ball Valves market is characterized by dynamic factors such as technological innovation, market competition, regulatory compliance, and end-user requirements. Manufacturers are continually investing in research and development to enhance valve performance, control features, and connectivity options, as well as exploring new market opportunities and strategic partnerships to drive innovation and market expansion. Moreover, industry standards, regulatory compliance, and quality assurance protocols play a significant role in shaping market dynamics and influencing product development and adoption trends in flow control technology.

Regional Analysis

The Electric Flow Control Ball Valves market is geographically segmented into regions such as North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. North America currently dominates the market, owing to the presence of leading manufacturers, technological innovation, and the adoption of advanced flow control solutions in industries such as oil and gas, water treatment, and HVAC. However, Asia-Pacific is emerging as a lucrative market for electric flow control ball valves, driven by rapid industrialization, urbanization, and infrastructure development in countries such as China, India, and Southeast Asia.

Competitive Landscape

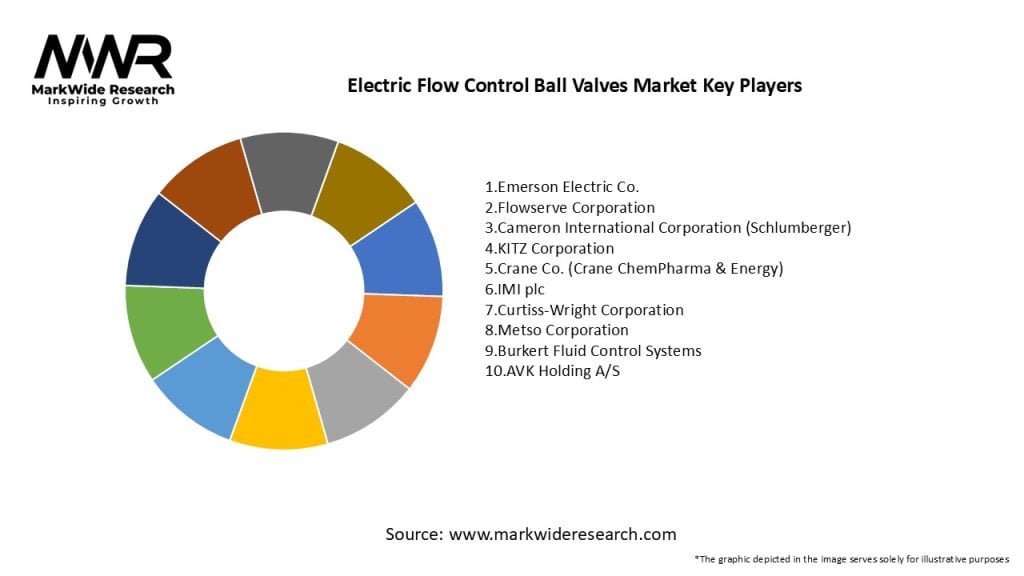

The Electric Flow Control Ball Valves market is highly competitive, with several key players vying for market share. Major players in the market include Emerson Electric Co., Flowserve Corporation, Cameron International Corporation, AVK Holding A/S, and Rotork plc. These companies are focusing on product innovation, research and development, and strategic partnerships to gain a competitive edge and expand their market presence globally.

Segmentation

The Electric Flow Control Ball Valves market can be segmented based on valve type, actuator type, control type, size, material, and end-user industry. By valve type, it includes floating ball valves, trunnion-mounted ball valves, and fully welded ball valves. By actuator type, it encompasses electric actuators, pneumatic actuators, and hydraulic actuators. By control type, it covers on-off control, modulating control, and emergency shutdown (ESD) control. By size, it includes quarter-turn valves, half-turn valves, and multi-turn valves. By material, it includes stainless steel, carbon steel, brass, and others. By end-user industry, it includes oil and gas, water treatment, HVAC, chemicals, pharmaceuticals, and others.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had mixed effects on the Electric Flow Control Ball Valves market, with disruptions to supply chains, project timelines, and investments in certain industries such as oil and gas, construction, and manufacturing. However, the pandemic has also underscored the importance of automation, remote operation, and digitalization in ensuring business continuity, operational resilience, and safety in industrial and commercial operations. Moving forward, electric flow control ball valves are expected to play a vital role in supporting the recovery and adaptation of industries to the post-pandemic business environment, driving investments in smart infrastructure, digital manufacturing, and sustainable development.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Electric Flow Control Ball Valves market is poised for continued growth and innovation in the coming years, driven by increasing investments in infrastructure development, industrial automation, and smart city projects worldwide. Technological advancements, market expansion into new regions and applications, and growing awareness about the benefits of electric flow control solutions for energy efficiency, sustainability, and operational optimization are expected to drive market growth. However, manufacturers need to address challenges such as technical complexities, price competition, and regulatory compliance to capitalize on growth opportunities and maintain market leadership in the dynamic and competitive flow control industry.

Conclusion

In conclusion, the Electric Flow Control Ball Valves market presents promising opportunities for businesses to meet the growing demand for precise, reliable, and energy-efficient flow control solutions in diverse industries such as oil and gas, water treatment, HVAC, and process automation. By leveraging technological advancements, product innovation, and strategic partnerships, manufacturers can develop next-generation electric flow control ball valves with enhanced performance, reliability, and functionality to address evolving customer needs and application requirements. Despite challenges such as technical complexities and market competition, the market is poised for sustained growth, driven by increasing investments in infrastructure development, industrial automation, and smart city initiatives worldwide. To succeed in this dynamic landscape, industry participants need to invest in research and development, foster collaboration and partnerships, and focus on innovation to stay ahead of the competition and meet the evolving needs of customers and end-users in the electric flow control ball valves market.

Electric Flow Control Ball Valves Market

| Segmentation Details | Description |

|---|---|

| Product Type | Standard Ball Valves, Trunnion Ball Valves, V-Port Ball Valves, Multi-Port Ball Valves |

| End User | Oil & Gas, Water Treatment, Chemical Processing, Power Generation |

| Installation | Onshore, Offshore, Industrial, Commercial |

| Control Type | Manual, Electric, Pneumatic, Hydraulic |

Leading Companies in the Electric Flow Control Ball Valves Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at