444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Duplex stainless steel pipes are a type of stainless steel pipes that exhibit a combination of ferritic and austenitic microstructures. These pipes are known for their superior strength, corrosion resistance, and excellent weldability. Duplex stainless steel pipes find extensive applications in various industries, including oil and gas, chemical processing, petrochemicals, and desalination plants.

Duplex stainless steel pipes are manufactured using a specific metallurgical process that creates a unique microstructure consisting of approximately 50% ferrite and 50% austenite. This balanced composition gives duplex stainless steel pipes their exceptional mechanical properties, making them ideal for demanding applications where high strength and resistance to corrosion are required.

Executive Summary

The global duplex stainless steel pipe market has been witnessing significant growth in recent years. The rising demand for corrosion-resistant materials, especially in the oil and gas industry, along with the increasing investments in infrastructure development, is driving the market’s growth. Additionally, the growing awareness about the benefits of duplex stainless steel pipes, such as their high strength and durability, is further propelling market expansion.

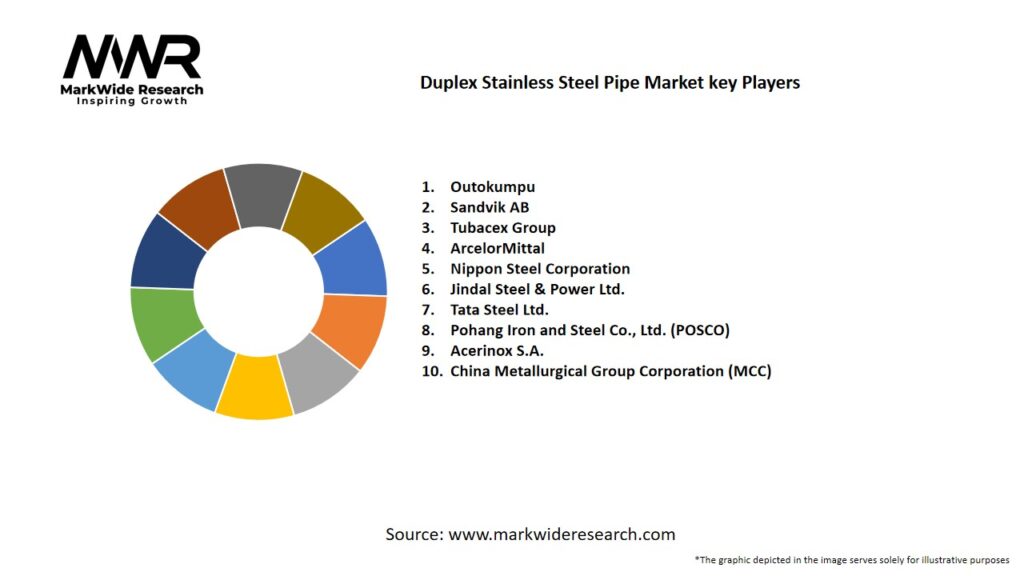

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The duplex stainless steel pipe market is characterized by intense competition among market players, technological advancements, and the adoption of various growth strategies. The market is driven by factors such as increasing demand from the oil and gas industry, infrastructure development projects, and the need for corrosion-resistant materials. However, challenges related to the high cost of duplex stainless steel pipes and complex manufacturing processes may restrict market growth. Nonetheless, emerging economies and advancements in manufacturing technologies provide promising opportunities for market expansion.

Regional Analysis

The global duplex stainless steel pipe market can be segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Currently, Asia Pacific holds the largest market share, driven by the rapid industrialization and infrastructure development in countries like China and India. North America and Europe are also significant markets due to the presence of well-established industries and stringent quality standards. Latin America and the Middle East and Africa are expected to witness considerable growth in the coming years due to the increasing investments in oil and gas exploration and infrastructure projects in these regions.

Competitive Landscape

Leading Companies in the Duplex Stainless Steel Pipe Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

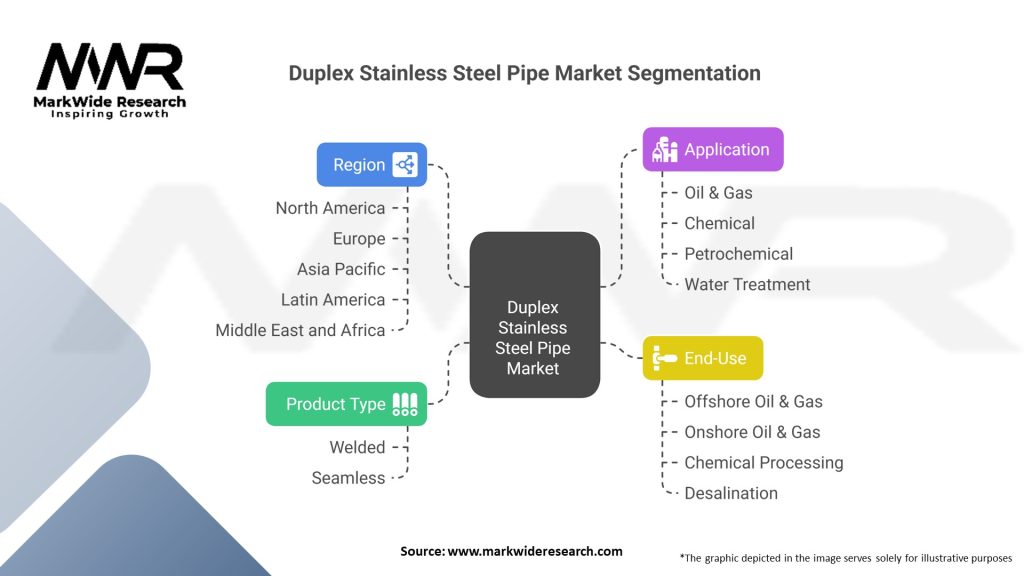

Segmentation

The duplex stainless steel pipe market can be segmented based on product type, manufacturing process, end-use industry, and region.

Category-wise Insights

Oil and Gas Industry The oil and gas industry is a major end-user of duplex stainless steel pipes. These pipes are used in various applications, including offshore drilling, subsea pipelines, and refineries. The oil and gas industry requires materials that can withstand extreme conditions, such as high-pressure and corrosive environments, making duplex stainless steel pipes an ideal choice. The increasing exploration activities and investments in offshore oil and gas fields are driving the demand for duplex stainless steel pipes in this sector.

Chemical Processing In the chemical processing industry, duplex stainless steel pipes are widely used due to their superior corrosion resistance and strength. These pipes are utilized in chemical reactors, storage tanks, and pipelines, where the transportation of corrosive chemicals is involved. The chemical processing industry relies on materials that can resist chemical reactions and maintain the integrity of the infrastructure. Duplex stainless steel pipes offer excellent resistance to a wide range of corrosive chemicals, making them indispensable in this industry.

Desalination Plants Desalination plants are crucial for producing freshwater from seawater or brackish water. Duplex stainless steel pipes are extensively used in desalination plants due to their excellent resistance to chloride-induced stress corrosion cracking and their ability to handle high-pressure seawater. As the global demand for freshwater continues to rise, the construction of desalination plants is increasing, leading to a growing demand for duplex stainless steel pipes in this sector.

Construction In the construction industry, duplex stainless steel pipes are used in various applications, including bridges, tunnels, and architectural structures. These pipes offer high strength, durability, and resistance to corrosion, making them suitable for demanding construction projects. The increasing investments in infrastructure development, urbanization, and architectural designs that require corrosion-resistant materials drive the demand for duplex stainless steel pipes in the construction sector.

Others Apart from the aforementioned industries, duplex stainless steel pipes find applications in various other sectors, such as pulp and paper, water treatment, and food processing. The pulp and paper industry utilizes duplex stainless steel pipes in pulp digesters, bleach plants, and chemical recovery units. Water treatment facilities employ these pipes for handling corrosive wastewater and chemicals. In the food processing industry, duplex stainless steel pipes are used for conveying food products and corrosive liquids.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The global duplex stainless steel pipe market experienced a moderate impact from the COVID-19 pandemic. The temporary shutdown of various industries, including oil and gas, construction, and chemical processing, disrupted the demand for duplex stainless steel pipes. However, as economies gradually recover and industries resume operations, the demand for these pipes is expected to rebound. The market is also witnessing a renewed focus on health and hygiene, leading to increased investments in water treatment and desalination projects, which will further drive the demand for duplex stainless steel pipes.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the duplex stainless steel pipe market appears promising, with steady growth projected over the forecast period. The increasing demand from industries such as oil and gas, chemical processing, and construction, coupled with the growing need for corrosion-resistant materials, will drive market expansion. Technological advancements, product innovations, and sustainability initiatives will shape the market’s trajectory. Additionally, emerging economies and infrastructure development projects will provide significant growth opportunities for market participants.

Conclusion

The global duplex stainless steel pipe market is witnessing robust growth, driven by the demand from various industries, including oil and gas, chemical processing, and construction. The unique properties of duplex stainless steel pipes, such as high strength, corrosion resistance, and weldability, make them a preferred choice in critical applications. Market players should focus on product development, strengthening distribution networks, and collaborating with end-use industries to capitalize on the growing demand. Despite challenges related to cost and complex manufacturing processes, the market’s future outlook remains optimistic, fueled by emerging economies, technological advancements, and sustainability initiatives.

What is Duplex Stainless Steel Pipe?

Duplex Stainless Steel Pipe refers to a type of pipe made from a stainless steel alloy that contains both austenitic and ferritic phases. This combination provides enhanced strength and corrosion resistance, making it suitable for various applications in industries such as oil and gas, chemical processing, and marine environments.

What are the key players in the Duplex Stainless Steel Pipe market?

Key players in the Duplex Stainless Steel Pipe market include Outokumpu, Sandvik, and Aperam, which are known for their high-quality stainless steel products. These companies focus on innovation and sustainability to meet the growing demand in various sectors, among others.

What are the growth factors driving the Duplex Stainless Steel Pipe market?

The Duplex Stainless Steel Pipe market is driven by factors such as the increasing demand for corrosion-resistant materials in the oil and gas industry, the growth of the chemical processing sector, and the rising need for durable construction materials in infrastructure projects.

What challenges does the Duplex Stainless Steel Pipe market face?

Challenges in the Duplex Stainless Steel Pipe market include fluctuating raw material prices, the complexity of manufacturing processes, and competition from alternative materials such as carbon steel and plastic pipes, which may limit market growth.

What opportunities exist in the Duplex Stainless Steel Pipe market?

Opportunities in the Duplex Stainless Steel Pipe market include the expansion of renewable energy projects, increased investments in infrastructure development, and the growing trend towards sustainable materials in construction and manufacturing.

What trends are shaping the Duplex Stainless Steel Pipe market?

Trends in the Duplex Stainless Steel Pipe market include advancements in manufacturing technologies, a shift towards more sustainable production practices, and an increasing focus on high-performance materials that can withstand extreme environments.

Duplex Stainless Steel Pipe Market

| Segmentation Details | Details |

|---|---|

| Product Type | Welded Duplex Stainless Steel Pipe, Seamless Duplex Stainless Steel Pipe |

| Application | Oil & Gas Industry, Chemical Industry, Petrochemical Industry, Water Treatment, Others |

| End-Use | Offshore Oil & Gas, Onshore Oil & Gas, Chemical Processing, Desalination, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Duplex Stainless Steel Pipe Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at