444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The digital shipbuilding market represents a transformative paradigm shift in the maritime industry, leveraging advanced technologies to streamline shipbuilding processes and enhance operational efficiency. This market segment encompasses a wide array of digital solutions and technologies aimed at optimizing design, construction, and maintenance processes within the shipbuilding ecosystem. From digital twins and augmented reality to blockchain-enabled supply chain management, digitalization is revolutionizing traditional shipbuilding practices, ushering in a new era of innovation and competitiveness.

Meaning

Digital shipbuilding refers to the integration of digital technologies and solutions across various stages of the shipbuilding lifecycle, encompassing design, engineering, production, and maintenance. It entails the utilization of digital tools such as computer-aided design (CAD), simulation software, Internet of Things (IoT) sensors, and data analytics to enhance collaboration, streamline workflows, and improve decision-making processes. By digitizing key aspects of shipbuilding operations, stakeholders can achieve greater precision, efficiency, and cost-effectiveness throughout the entire lifecycle of a vessel.

Executive Summary

The digital shipbuilding market is undergoing rapid evolution driven by the imperative for shipyards and maritime companies to embrace digital transformation. With the proliferation of advanced technologies and the growing demand for smarter, more sustainable vessels, the adoption of digital solutions has become imperative for maintaining competitiveness in the global shipbuilding landscape. From virtual prototyping and digital twinning to predictive maintenance and remote monitoring, digitalization offers a plethora of benefits for industry stakeholders. However, challenges such as data security concerns, interoperability issues, and workforce upskilling requirements need to be addressed to unlock the full potential of digital shipbuilding.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The digital shipbuilding market is characterized by rapid technological advancements, shifting customer expectations, and evolving regulatory landscapes. Industry players must adapt to these dynamics by embracing digital transformation, fostering innovation, and forging strategic partnerships. Collaboration across the value chain, from ship designers and manufacturers to software developers and service providers, is essential for driving market growth and unlocking new opportunities.

Regional Analysis

The adoption of digital shipbuilding technologies varies across regions, influenced by factors such as technological infrastructure, regulatory frameworks, and market demand. While established maritime hubs in Europe and Asia lead in terms of innovation and digitalization initiatives, emerging markets in Latin America and Africa offer untapped potential for digital shipbuilding solutions. Regional disparities in digital readiness and investment climate shape the trajectory of the digital shipbuilding market on a global scale.

Competitive Landscape

Leading Companies in the Digital Shipbuilding Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

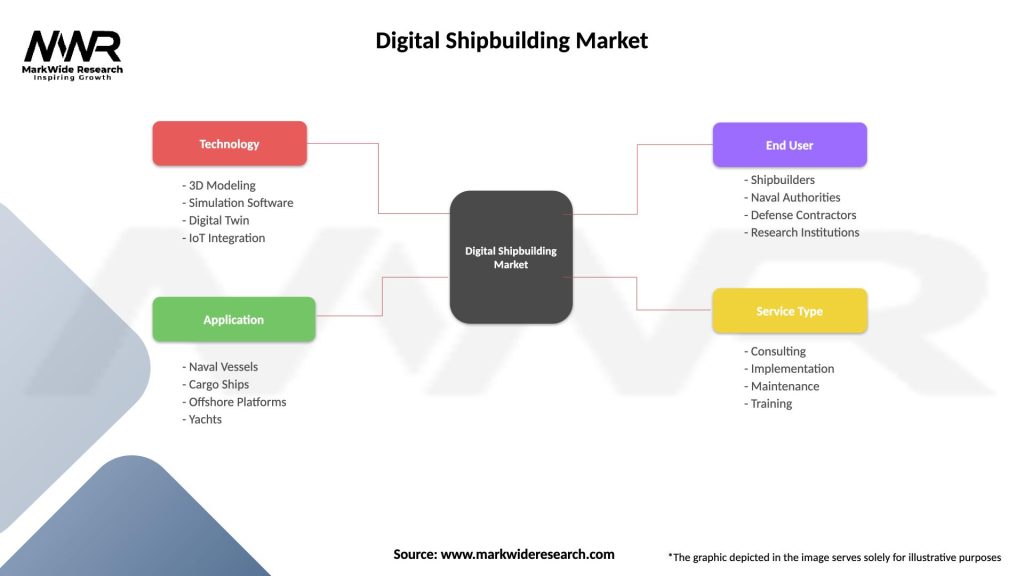

The digital shipbuilding market can be segmented based on various factors, including:

Segmentation enables stakeholders to tailor their digitalization strategies and offerings to specific market segments and customer segments, thereby maximizing value creation and market penetration.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT analysis of the digital shipbuilding market reveals the following:

A nuanced understanding of these factors enables industry participants to capitalize on strengths, address weaknesses, leverage opportunities, and mitigate threats effectively.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has accelerated digitalization efforts in the shipbuilding industry, prompting stakeholders to adopt remote working, virtual collaboration, and digital twin technologies to mitigate disruptions and ensure business continuity. While the pandemic has posed challenges such as supply chain disruptions and workforce shortages, it has also underscored the importance of digital transformation in building resilience and adaptability.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the digital shipbuilding market is promising, with continued advancements in technology, increasing demand for smarter, more sustainable vessels, and growing regulatory pressures driving market growth. Industry players that embrace digital transformation, invest in innovation, and foster collaboration are poised to capitalize on emerging opportunities and thrive in the digital age.

Conclusion

The digital shipbuilding market represents a transformative force within the maritime industry, offering stakeholders the tools and technologies needed to drive efficiency, innovation, and sustainability across the shipbuilding lifecycle. From virtual design and engineering to remote monitoring and predictive maintenance, digitalization enables shipbuilders to create smarter, safer, and more sustainable vessels that meet the demands of the modern maritime market. By embracing digital transformation, addressing key challenges, and seizing emerging opportunities, industry participants can navigate the complexities of the digital shipbuilding landscape and build a more resilient and competitive future.

What is Digital Shipbuilding?

Digital Shipbuilding refers to the integration of digital technologies in the shipbuilding process, enhancing design, construction, and maintenance through tools like simulation, data analytics, and automation.

What are the key players in the Digital Shipbuilding Market?

Key players in the Digital Shipbuilding Market include companies like Siemens, ABB, and Rolls-Royce, which are known for their innovative solutions in ship design and manufacturing, among others.

What are the main drivers of growth in the Digital Shipbuilding Market?

The main drivers of growth in the Digital Shipbuilding Market include the increasing demand for efficiency in ship production, the need for advanced technologies to reduce costs, and the growing emphasis on sustainability in maritime operations.

What challenges does the Digital Shipbuilding Market face?

Challenges in the Digital Shipbuilding Market include the high initial investment required for digital technologies, the need for skilled workforce to operate advanced systems, and potential cybersecurity risks associated with digital integration.

What opportunities exist in the Digital Shipbuilding Market?

Opportunities in the Digital Shipbuilding Market include the potential for developing smart ships, advancements in automation and robotics, and the increasing adoption of digital twins for enhanced operational efficiency.

What trends are shaping the Digital Shipbuilding Market?

Trends shaping the Digital Shipbuilding Market include the rise of artificial intelligence in design processes, the use of big data for predictive maintenance, and the growing focus on environmentally friendly shipbuilding practices.

Digital Shipbuilding Market

| Segmentation Details | Description |

|---|---|

| Technology | 3D Modeling, Simulation Software, Digital Twin, IoT Integration |

| Application | Naval Vessels, Cargo Ships, Offshore Platforms, Yachts |

| End User | Shipbuilders, Naval Authorities, Defense Contractors, Research Institutions |

| Service Type | Consulting, Implementation, Maintenance, Training |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Digital Shipbuilding Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at